Process for high-efficiently laser three-dimensional (3D) printing Fe-based amorphous component

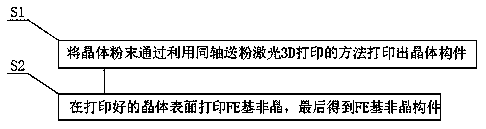

A 3D printing and laser technology, applied in the field of high-efficiency laser 3D printing Fe-based amorphous components, can solve the problems of low amorphous content and crack production efficiency, and achieve the effect of high amorphous content and lower raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 430 stainless steel powder with a particle size of 20 μm~200 μm and Fe 41 co 7 Cr 15 Mo 14 C 15 B 6 Y 2 (Atomic percent, at%) amorphous alloy powders were placed in two powder feeding barrels of the coaxial powder feeding laser 3D printer.

[0029] Using the coaxial powder feeding laser 3D printing equipment, the 430 stainless steel powder with a particle size of 20μm~200μm was processed under the conditions of laser power 600W, scanning speed 600mm / min, laser spot diameter 2mm, and oxygen content in the printing environment below 10ppm. A square 430 stainless steel component with a length of 40 mm, a width of 10 mm and a height of 10 mm was printed on a 45# steel substrate with a thickness of 10 mm.

[0030] After the above-mentioned 430 stainless steel components were naturally cooled in the printing chamber for 30 min, the laser starting coordinates were recalibrated. Fe in the other powder bucket 41 co 7 Cr 15 Mo 14 C 15 B 6 Y 2 Amorphous alloy powder ...

Embodiment 2

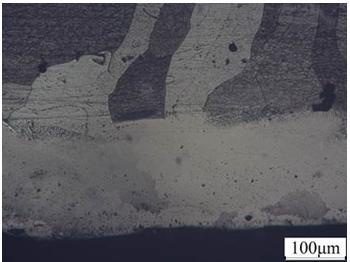

[0033] The difference between this embodiment and Embodiment 1 is: after the 430 stainless steel member is naturally cooled in the printing chamber for 60 minutes, the laser starting coordinates are recalibrated. Fe-based amorphous was printed with laser power of 900 W and scanning speed of 3000 mm / min. Others are the same as in Example 1. Under the process conditions, a crack-free Fe-based amorphous printing component can be obtained, and the Fe-based amorphous is well bonded to 430 stainless steel without obvious bonding traces.

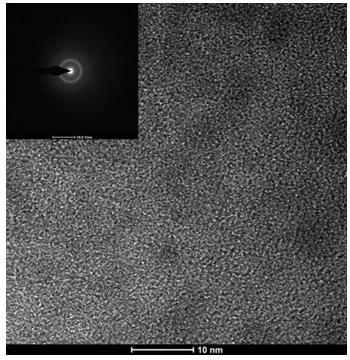

[0034] image 3 In order to print the transmission electron microscope image of Fe-based amorphous components, it can be seen from the figure that the printed Fe-based amorphous components have a disordered structure, and the electron diffraction pattern is a typical amorphous diffraction halo, which can prove that the printed non-crystalline The crystal member is fully amorphous. Figure 4 To print the Vickers hardness map of 430 stainless stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com