Electronic chip soldering device

A technology for welding devices and electronic chips, which is applied in the direction of electric heating devices, tin feeding devices, auxiliary devices, etc., can solve problems such as connection points and weak welding, and achieve the effect of low proficiency, low requirements, uniform and stable welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

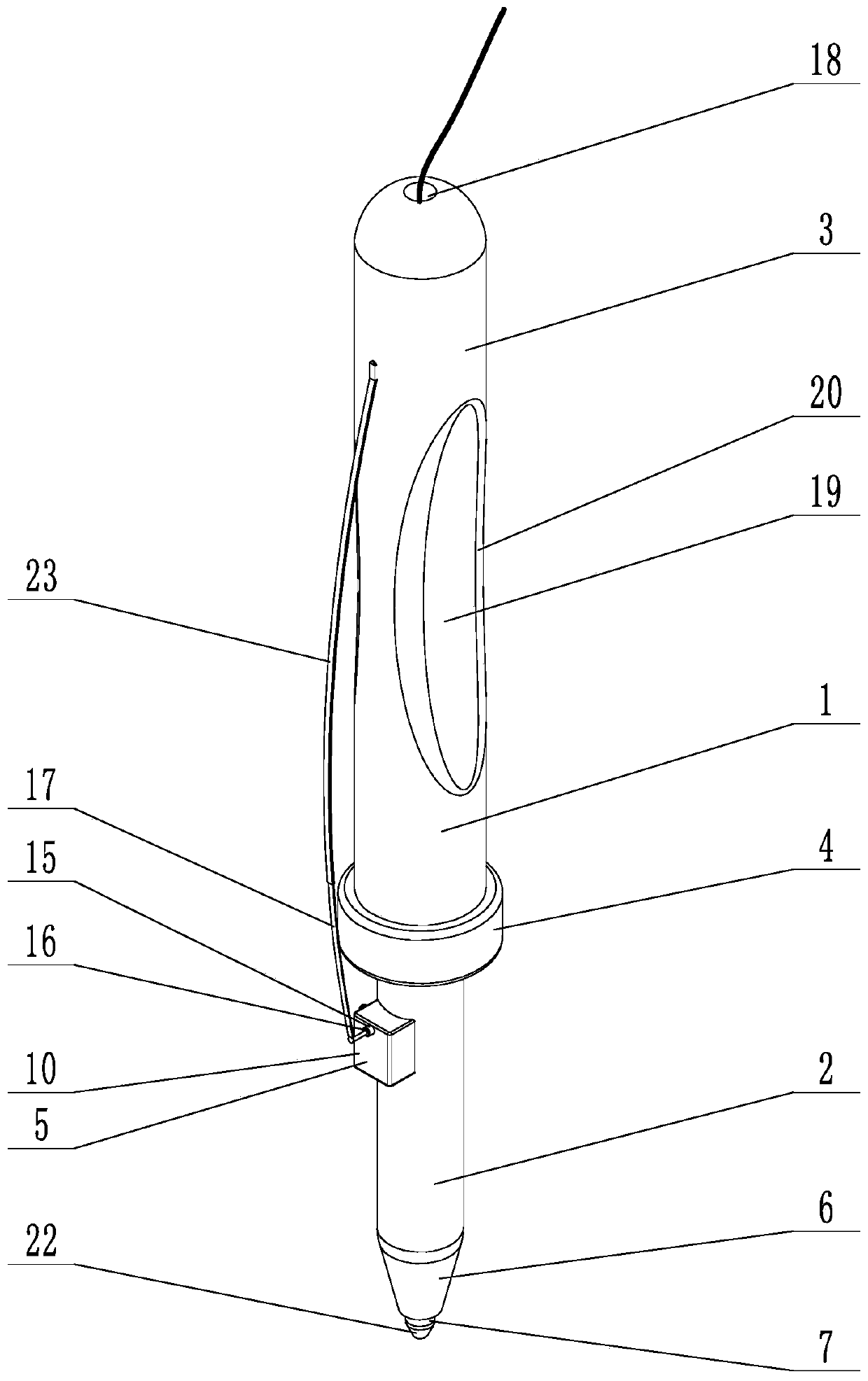

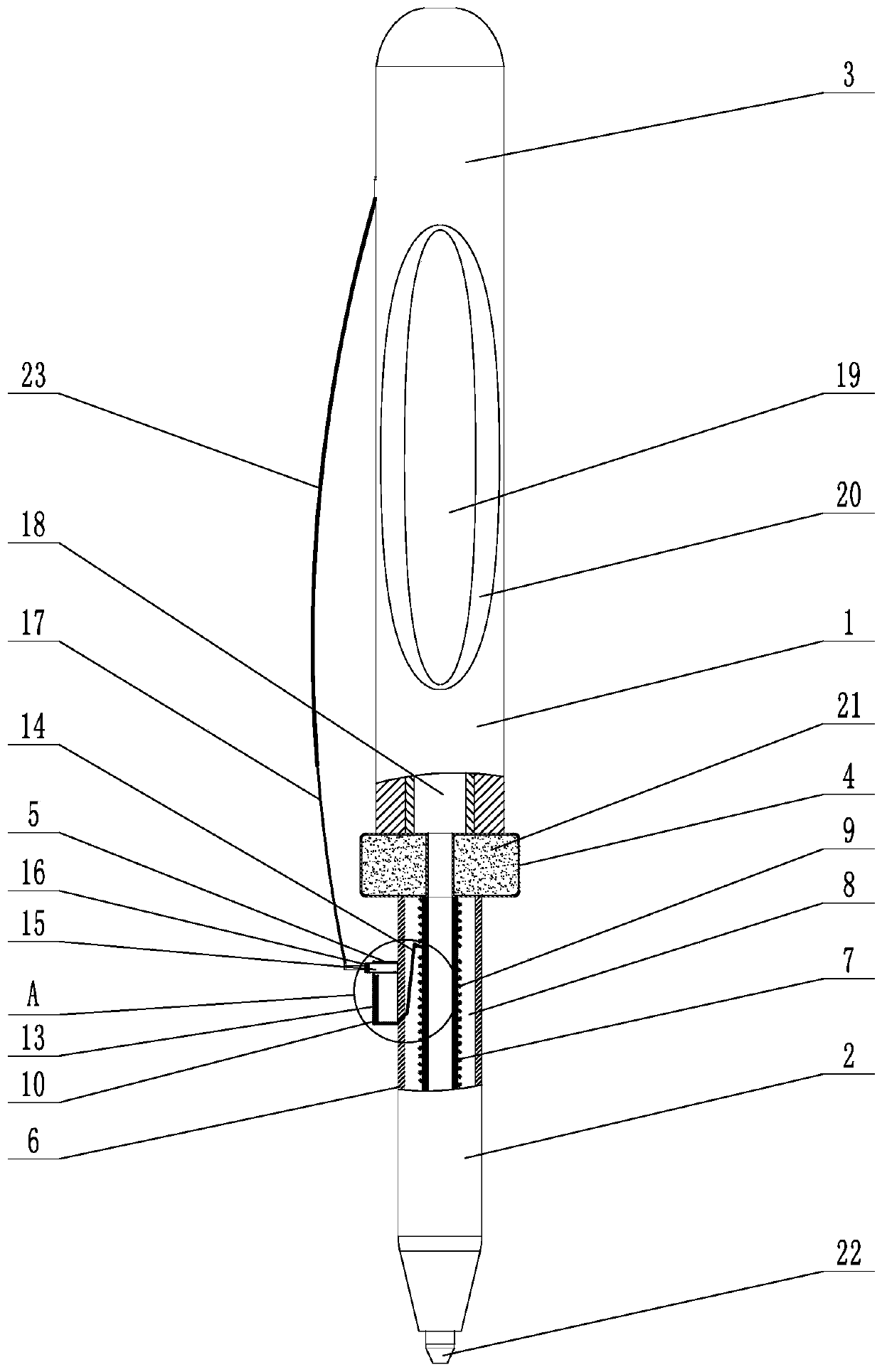

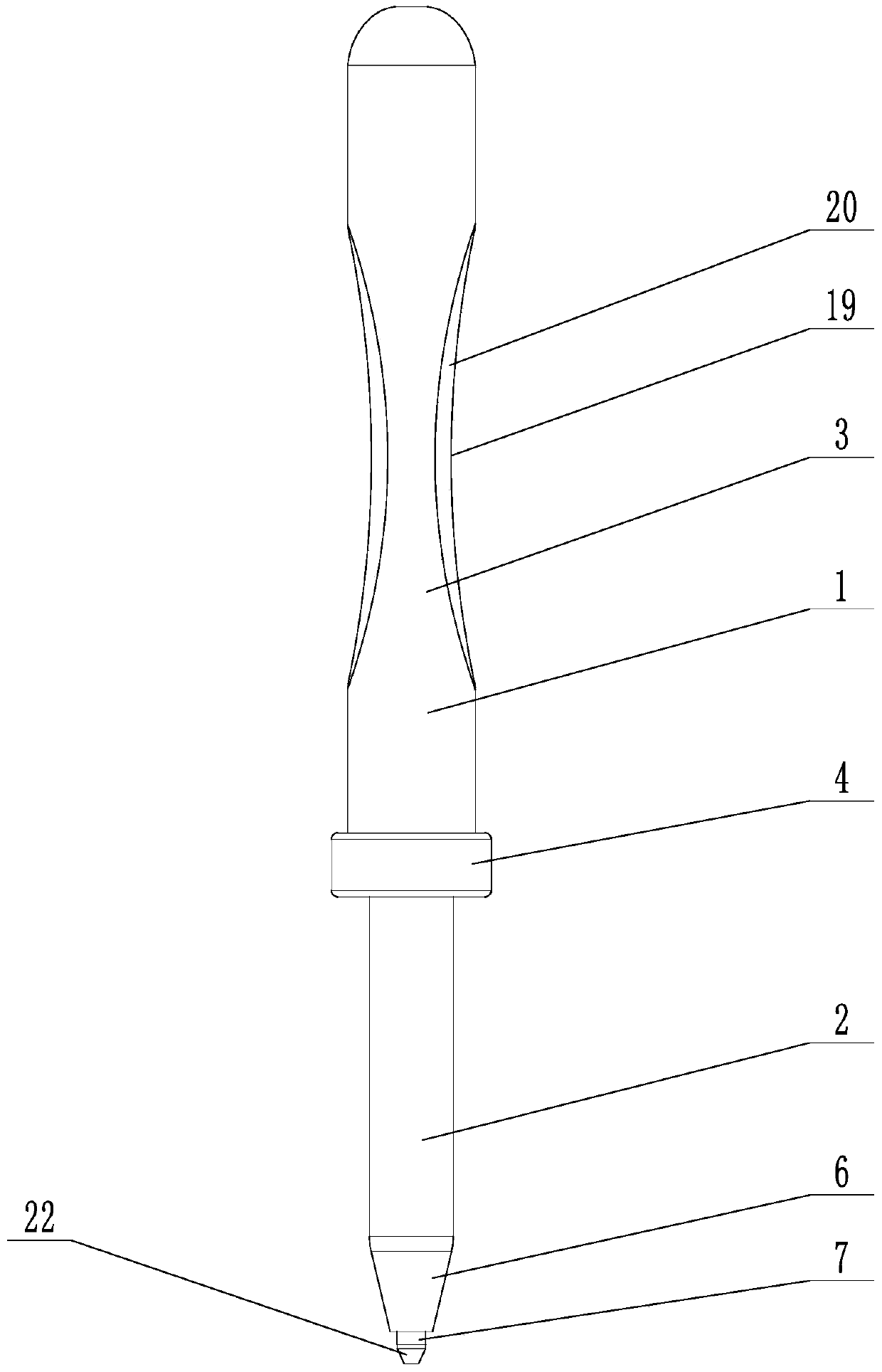

[0038]An electronic chip soldering device includes a soldering pen body 1, the soldering pen body 1 includes a soldering portion 2 and a hand-held portion 3, the soldering portion 2 is located below the hand-held portion 3, and between the soldering portion 2 and the hand-held portion 3 A connecting portion 4 is provided, and a hot-melting portion 5 is provided on the welding portion 2 . The welded portion 2 includes an outer layer 6 and an inner tube 7, and the outer layer and the inner tube are both made of metal. Between the outer layer 6 and the inner tube 7 is a heating chamber 8 , and the tops of the outer layer 6 and the inner tube 7 are welded to the connecting portion 4 . The outer layer 6 is tapered, the diameter of the outer layer 6 gradually decreases from top to bottom, a through hole is formed at the bottom of the outer layer, the through hole passes through the heating chamber 8, and the inner tube 7 passes through the through hole Exposed to the outside, a hea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap