How to change the color of float glass

A float glass and glass plate technology, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of long duration of color change cycle, shorten the color change time, speed up homogenization, and increase the temperature difference between the upper and lower sides Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

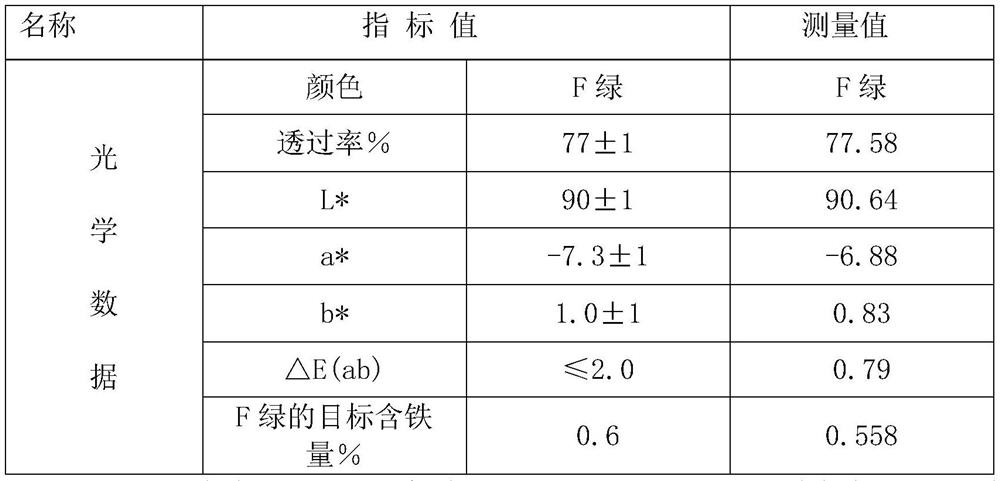

Embodiment 1

[0048] This example prepares a method for changing the color of float glass, specifically converting colorless glass into green glass by using a transitional replacement method, including the following steps:

[0049] S11. Provide a melting furnace and a tin tank, the inlet end of the tin tank is connected to the end of the melting furnace, the inlet end includes a flow channel, and the melting furnace includes a feeding port, a melting part, a neck and a cooling furnace arranged in sequence The melting part is provided with a bubbler, the neck is provided with a water bag and a stirrer, the outlet end of the cooling part is connected to the tin tank with the flow channel, and the cooling part is loaded with a diluted Fans and spray guns;

[0050] S12, using a mixture of F green cullet, transition color glass and iron powder as a coloring material, putting the coloring material into the feeding port, so that the coloring material is continuously mixed with the colorless glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com