A kind of energy-absorbing shock-absorbing PC/ABS alloy and preparation method thereof

A technology of shock absorption and ABS resin, which is applied in the field of polymer material processing, can solve the problems that the energy absorption and shock absorption of PC/ABS alloys cannot meet the requirements of use, and achieve increased rigidity, improved energy absorption and surface impact performance, and high compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

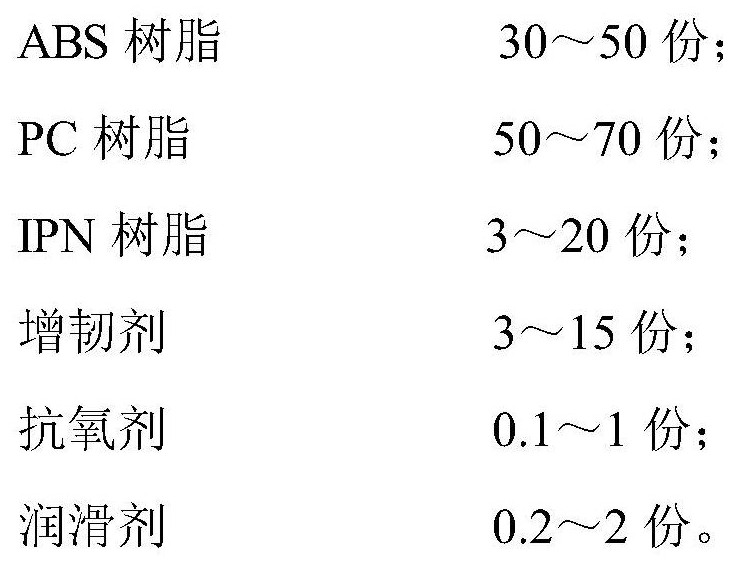

Method used

Image

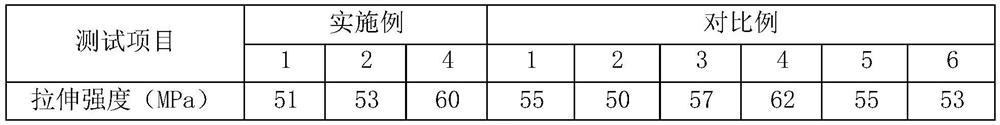

Examples

Embodiment 1

[0052] This embodiment provides an energy-absorbing and shock-absorbing PC / ABS alloy and a preparation method thereof, the method comprising the following steps:

[0053] (1) Weigh each component by weight: PC: 50, ABS: 30, toughening agent: 15; antioxidant 0.1, lubricant 0.2, IPN resin 3.

[0054] (2) Feed the raw materials ABS resin, PC resin, toughener, antioxidant and lubricant from the feeding port, feed the IPN resin into the seventh zone, and melt and extrude it at 200-280°C. The rotating speed of the extruder is 400rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

[0055] (3) The screw diameter of the extruder is 40 mm, and the aspect ratio is 42.

Embodiment 2

[0057] This embodiment provides an energy-absorbing and shock-absorbing PC / ABS alloy and a preparation method thereof, the method comprising the following steps:

[0058] (1) Weigh each component by weight: PC: 60, ABS: 40, toughening agent: 5; antioxidant 0.2, lubricant 0.3, IPN resin 10.

[0059] (2) Feed the raw materials ABS resin, PC resin, toughener, antioxidant and lubricant from the feeding port, feed the IPN resin into the seventh zone, and melt and extrude it at 200-280°C. The rotating speed of the extruder is 400rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

[0060] (3) The screw diameter of the extruder is 40 mm, and the aspect ratio is 42.

Embodiment 3

[0062] This embodiment provides an energy-absorbing and shock-absorbing PC / ABS alloy and a preparation method thereof, the method comprising the following steps:

[0063] (1) Weigh each component by weight: PC: 70, ABS: 50, toughening agent: 3; antioxidant 1, lubricant 2, IPN resin 20.

[0064] (2) Feed the raw materials ABS resin, PC resin, toughener, antioxidant and lubricant from the feeding port, feed the IPN resin into the seventh zone, and melt and extrude it at 200-280°C. The rotating speed of the extruder is 400rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

[0065] (3) The screw diameter of the extruder is 40 mm, and the aspect ratio is 42.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com