Die casting magnesium alloy steering column support

A steering column and alloy technology, which is applied to the steering column and the steering control installed on the car, etc., can solve the problems that affect the adjustment accuracy of the steering column, the rack assembly error is difficult to eliminate, and the rack strength is not very ideal. , to achieve the effect of reducing weight, eliminating assembly errors, and improving damping and shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

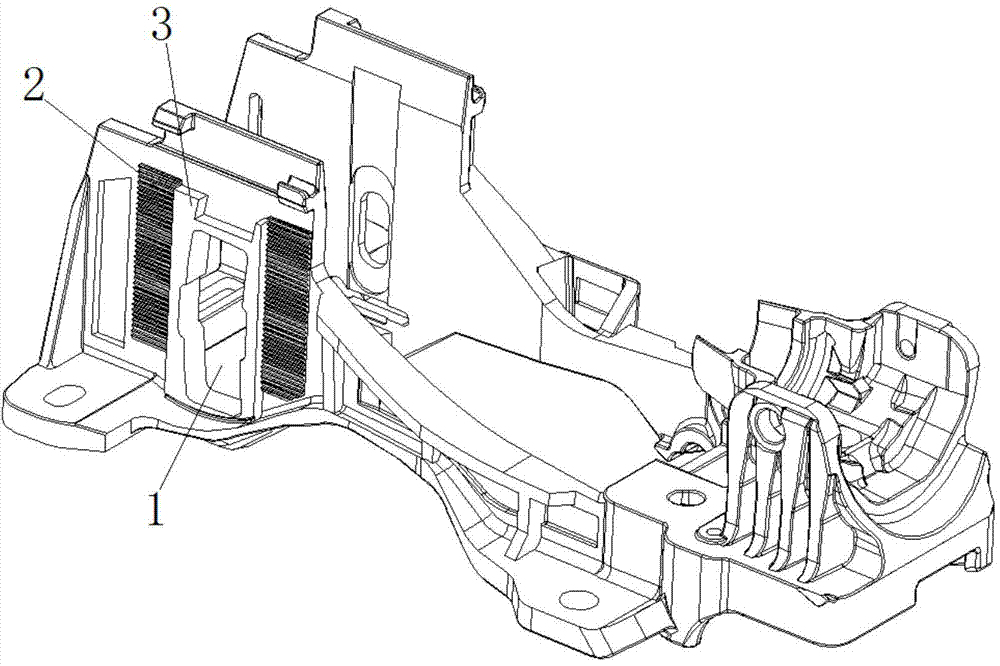

[0014] Such as figure 1 As shown, a die-casting magnesium alloy steering column bracket includes an installation slot 1 for installing an adjustment mechanism, and the installation slot 1 is used for installing the adjustment mechanism of the steering column.

[0015] A rack 2 is arranged on both sides of the installation slot 1, and the rack 2 is used for adjusting the steering column. In order to enhance the bite strength of the rack 2 here, the rack 2 is a helical rack, the top of the teeth of the rack 2 and the bottom of the alveolar are rounded, and the alveolar is the tooth and the tooth. The diameter of the fillet at the top of the tooth is 0.35 mm, and the diameter of the fillet at the bottom of the alveolar is 0.25 mm.

[0016] A boss 3 is arranged around the mounting slot 1, and the boss 3 is also formed by one-time die-casting. The height of the boss 3 above the rack 1 is 1.5 mm. The arrangement of the boss 3 reduces the adjustment stroke of the steering column ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com