Damping rubber

A shock-absorbing glue and damping technology, applied in the field of damping and shock-absorbing glue, can solve the problems of large dust, large working space and large consumption in coating factories, and achieve the effects of high shock-proof quality, weight reduction and consumption reduction.

Pending Publication Date: 2022-05-24

张家港爱科思汽车配件有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The asphalt damping plate used in the painting factory now has problems such as manual operation, spraying on unnecessary parts, large consumption, large working space, and large dust in the painting factory.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] Below in conjunction with embodiment, the technical scheme of the present invention is further described:

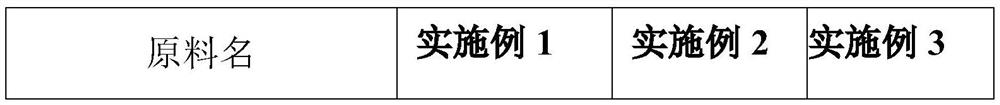

[0018] Raw material quality (Kg)

[0019]

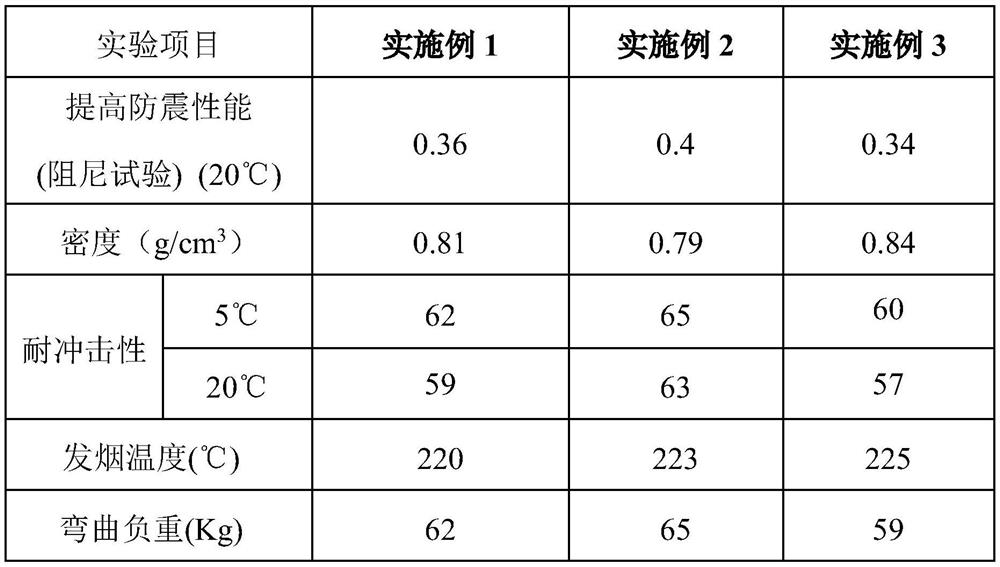

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses damping shock absorption rubber which is prepared from the following components in parts by mass: 35-40 parts of rubber nanospheres, 40-65 parts of water-soluble acrylic resin, 5-10 parts of light calcium carbonate, 10-11 parts of water, 2.0-2.6 parts of a foaming agent, 2-3.5 parts of carbon black, 0.2-0.5 part of a tackifier, 5-8 parts of dioctyl terephthalate and / or diisononyl phthalate, 2-8 parts of carbon nanotubes, 1-3 parts of an adhesion promoter, 1-4 parts of a stabilizer and 3-5 parts of a flexibilizer. By adding a certain proportion of rubber nanospheres, the elastic effect of the rubber nanospheres is effectively utilized, and after the rubber nanospheres are adhered to the surface of an automobile through water-soluble acrylic resin, a very good damping effect is achieved; and by adding the light calcium carbonate and the carbon nanotubes, the weight of the coating is greatly reduced while the strength of the coating is ensured, and the light weight of the coating is realized.

Description

technical field [0001] The invention relates to a damping glue, in particular to a damping damping glue. Background technique [0002] Vibration is ubiquitous in real life, and the phenomenon of vibration cannot be ignored and indispensable. People have been devoted to the research on the generation, control and elimination of vibration. However, vibration will also have many adverse effects on people's lives. For example, resonance will cause damage to mechanical equipment, and noise generated by cars, high-speed trains, etc. will affect the living environment of human beings. How to reduce the adverse effects of vibration on people? Minimizing is the current development and pursuit of shock absorption technology. [0003] The requirements for low cost, high quality and noise reduction of vehicles are increasing every year. In order to meet the market demand, noise reduction materials have developed rapidly. The representative asphalt damping plate among noise reduction ag...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L33/00C08L7/00C08L23/22C08L9/00C08K3/04C08K5/12C08K3/26C08J9/04

CPCC08J9/04C08J9/0061C08J9/0066C08J9/0071C08J9/0023C08J2333/00C08J2407/00C08J2423/22C08J2409/00

Inventor 牛方方张世俊王星陈鑫鑫

Owner 张家港爱科思汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com