Method and apparatus for producing high porosity through hole multi-hole aluminum alloy

A technology with high porosity and aluminum alloy, which is applied in the field of metal material processing to achieve the effect of uniform skeleton, high through-hole degree and increased uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 A method for manufacturing a high-porosity through-hole porous aluminum alloy includes the following steps: first, weigh a certain mass of aluminum alloy (the aluminum alloy can be an aluminum-silicon alloy containing 6% to 11% silicon or an aluminum-silicon alloy containing Copper 4-10% aluminum-copper alloy), the quality is the actual aluminum alloy casting quality, heat it to melt, keep the aluminum alloy melt temperature at 660°C-750°C, the temperature can be 660°C, 680°C, 700°C ℃, 750℃, put the filler particles into the mold 1, keep warm at 500℃~660℃ until the temperature of the filler particles is uniform, the temperature can be 500℃, 550℃, 600℃, 620℃, 640℃, 660℃, where : Actual aluminum alloy casting quality = theoretical aluminum alloy casting quality + margin, theoretical aluminum alloy casting quality = filler particle accumulation height × filler particle accumulation cross-sectional area × aluminum alloy density × (1-porous aluminum alloy porosity),...

Embodiment 2

[0017] Example 2 A high-porosity through-hole porous aluminum alloy obtained by the method described in Example 1 (the aluminum alloy can be an aluminum-silicon alloy containing 6% to 11% silicon or an aluminum-copper alloy containing 4-10% copper) , its porosity is 70% to 95%, the porosity can be 70%, 75%, 78%, 80%, 85%, 90%, 95%, the shape of the pores is polygonal or spherical, the pores are evenly distributed, and the average pore size 0.5-7mm, can be 0.5mm, 1.0mm, 3mm, 5mm, 7mm, and the through hole can reach 20%-35%.

Embodiment 3

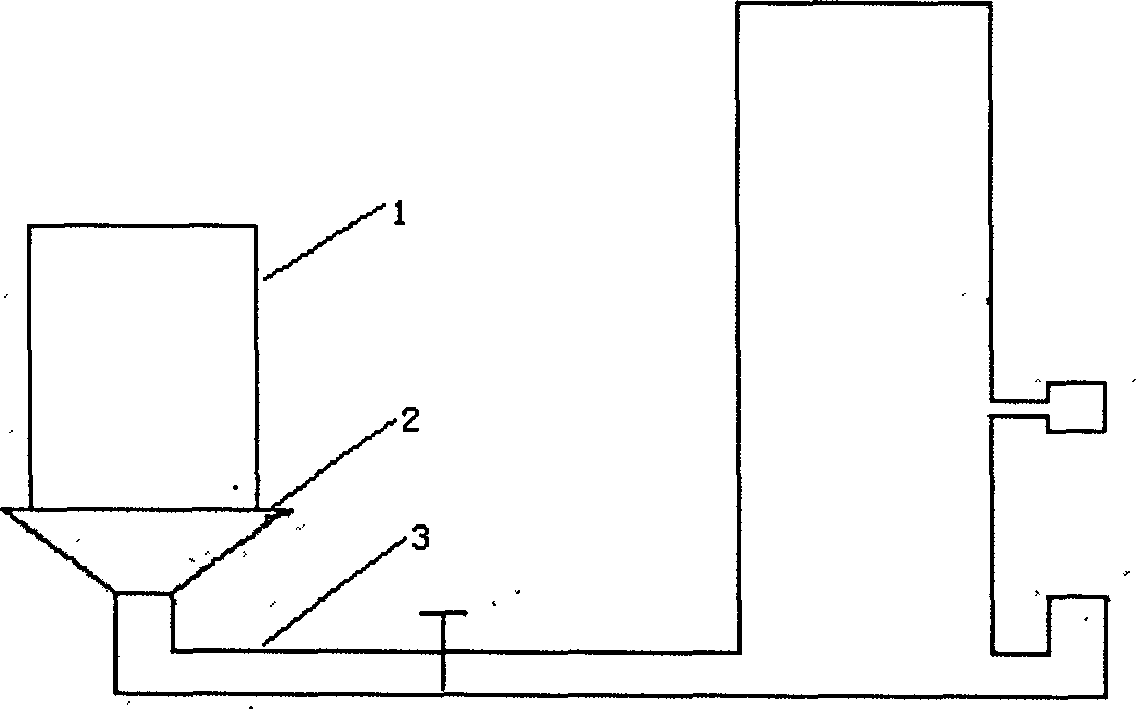

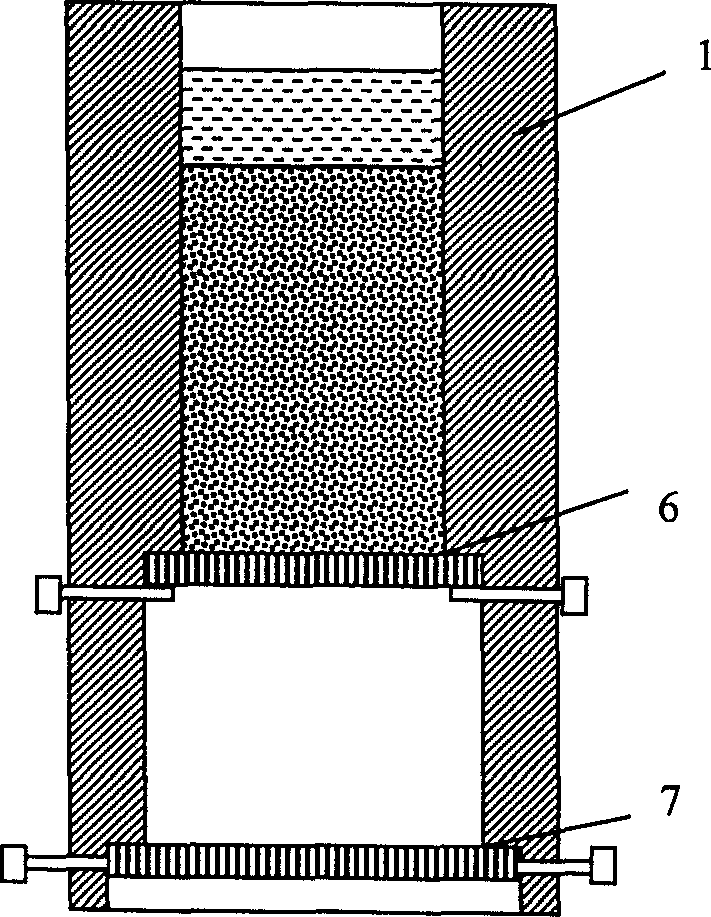

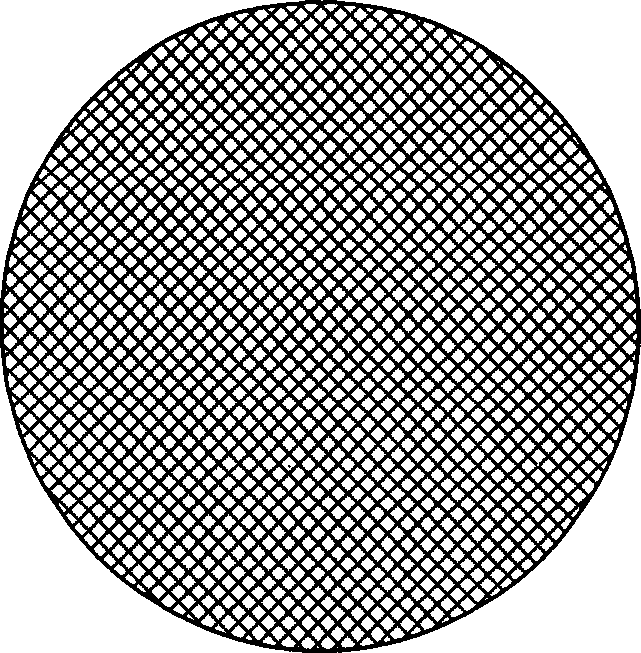

[0018] Example 3 A special device for manufacturing high-porosity through-hole porous aluminum alloys used in the method described in Example 1, including a negative pressure system 3 and a mold 1, one end of the mold 1 is connected to the negative pressure system 3, and inside the mold 1 An upper base plate 6 and a lower base plate 7 are placed, wherein the upper base plate 6 is a barbed wire mesh with a grid side length of 2 to 6 mm, and the side length can be 2 mm, 4 mm, and 6 mm, and the lower base plate 7 is pasted with 100 to 200 meshes (which can be 100 mesh, 150 mesh, 200 mesh) the hole diameter of the barbed wire is 2-6mm orifice plate, the hole diameter can be 2mm, 4mm, 6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com