Multi-functional rotary plastering board

A multi-functional, rotating direction technology, applied in the direction of construction, building structure, etc., can solve the problems of high labor intensity, low efficiency, cumbersome work process, etc., and achieve the effect of improving work efficiency, ensuring flatness, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

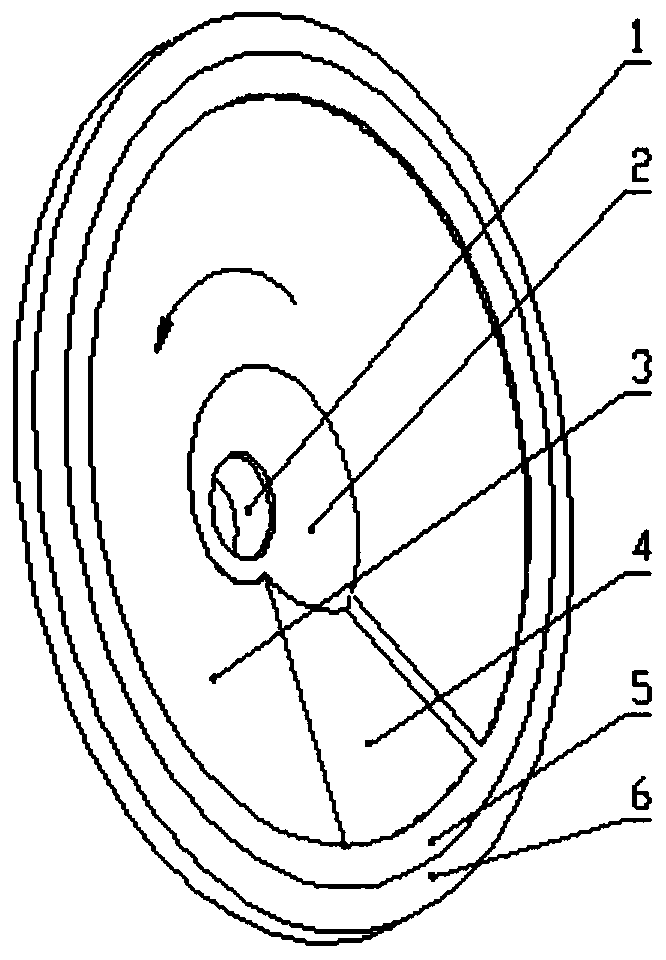

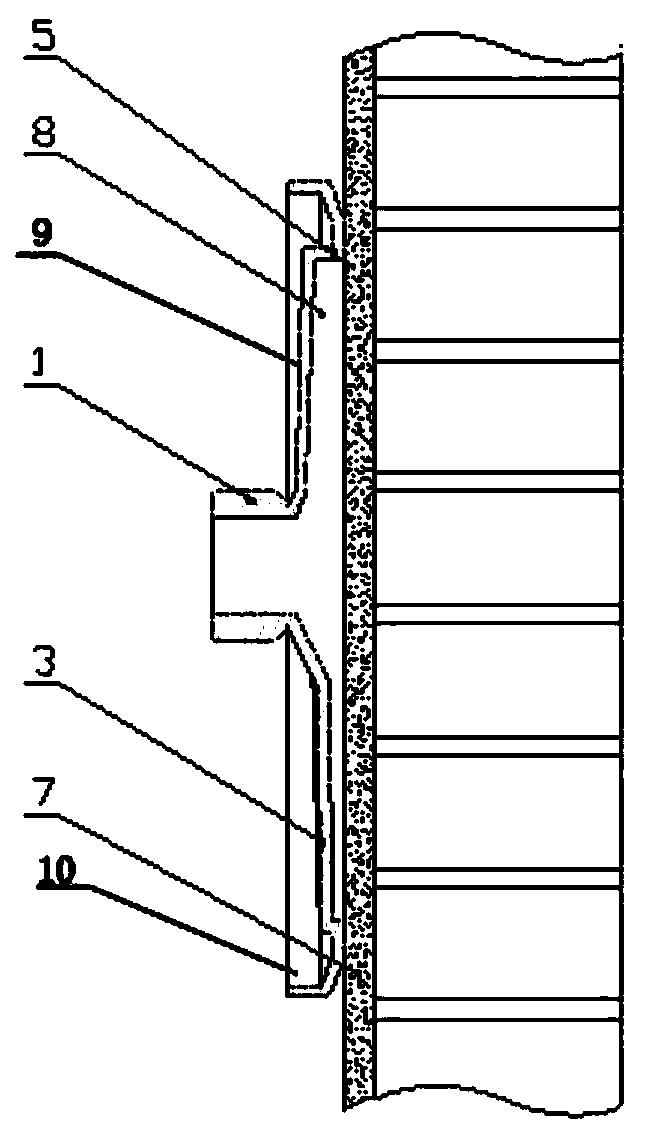

[0032] A multi-functional rotary wiper, such as figure 1 , figure 2 As shown, it includes a wiper 10, the wiper 10 is provided with a concave cavity 9, the middle of the concave cavity 9 is provided with a feed port 1, and the inner surface of the concave cavity 9 is a spiral surface a connected to each other. 3 and the helical surface b 4 , the helicoid a 3 and the helicoid b 4 rotate in opposite directions, and the edge of the concave cavity 9 is provided with a protruding cavity outer edge 5 . In the multifunctional rotary wiper of the present invention, a concave cavity 9 filled with materials is provided on the wiper 10, and a feed port 1 is provided in the middle of the concave cavity 9, and the feed port 1 is connected to the feed pipe to feed the concave cavity 9. Feeding in the cavity 9, the wiper 10 rotates with the central axis of the feed port 1 as the center of rotation, and the feed pipe continues to feed into the concave cavity 9 to ensure that the working tra...

Embodiment 2

[0034] Based on the above-mentioned embodiment 1, such as figure 1 As shown, the feed port 1 is provided with an overflow port 2 . When the material inlet 1 is provided with an overflow port 2, the material 8 entering from the material inlet 1 overflows outwards evenly through the overflow port 2, thereby ensuring that the material 8 is evenly arranged on the inner surface of the concave cavity 9. In this embodiment, the overflow port 2 is preferably conical. In addition, it is not limited to the conical shape, and other shapes can also be selected, such as flat cylinder, spiral and so on. In this embodiment, other content not described is the same as that in the foregoing embodiment, and will not be repeated here.

Embodiment 3

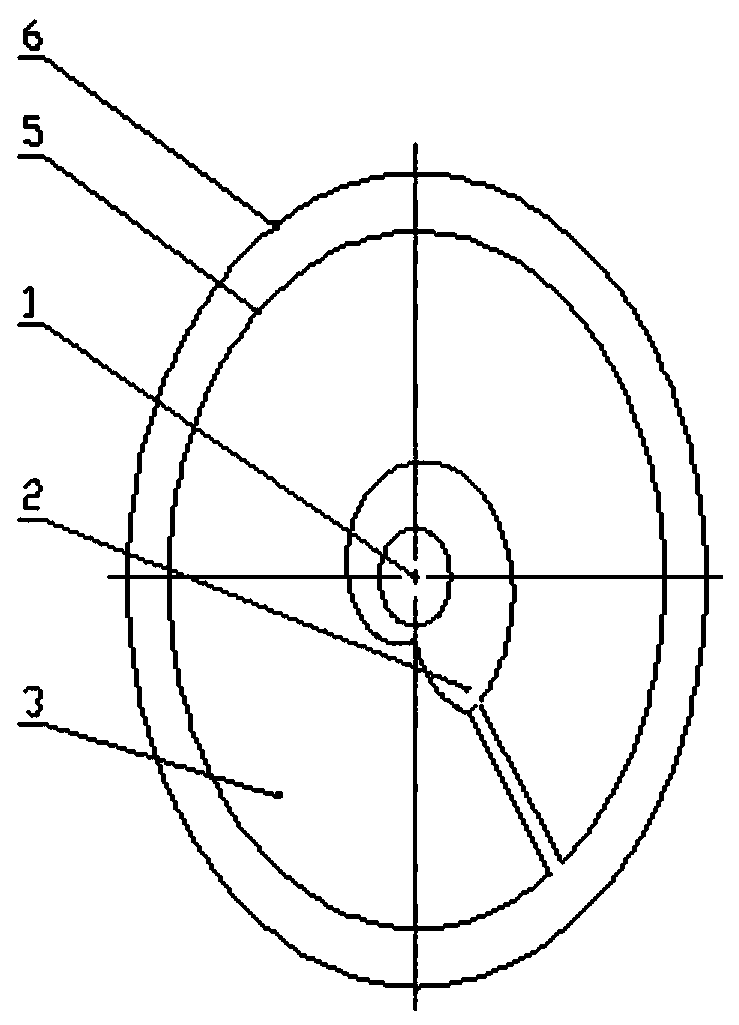

[0036] Based on the above-mentioned embodiment 1, such as image 3 As shown, the central axis of the feeding port 1 coincides with the central axis of the wiper 10 . The central axis of the feed port 1 coincides with the central axis of the wiper 10, and the wiper 10 rotates coaxially with the central axis of the feed port 1; when the wiper moves in this way, it can prevent the wall 7 from extruding flange-like lines. In this embodiment, other content not described is the same as that in the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com