Advanced support structure applicable to unconsolidated formation and construction method thereof

A technology of advanced support and construction method, which is applied in the direction of earth square drilling, mine roof support, mining equipment, etc., to achieve the effect of increasing corrosion resistance, improving pressure bearing capacity, enhancing integrity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

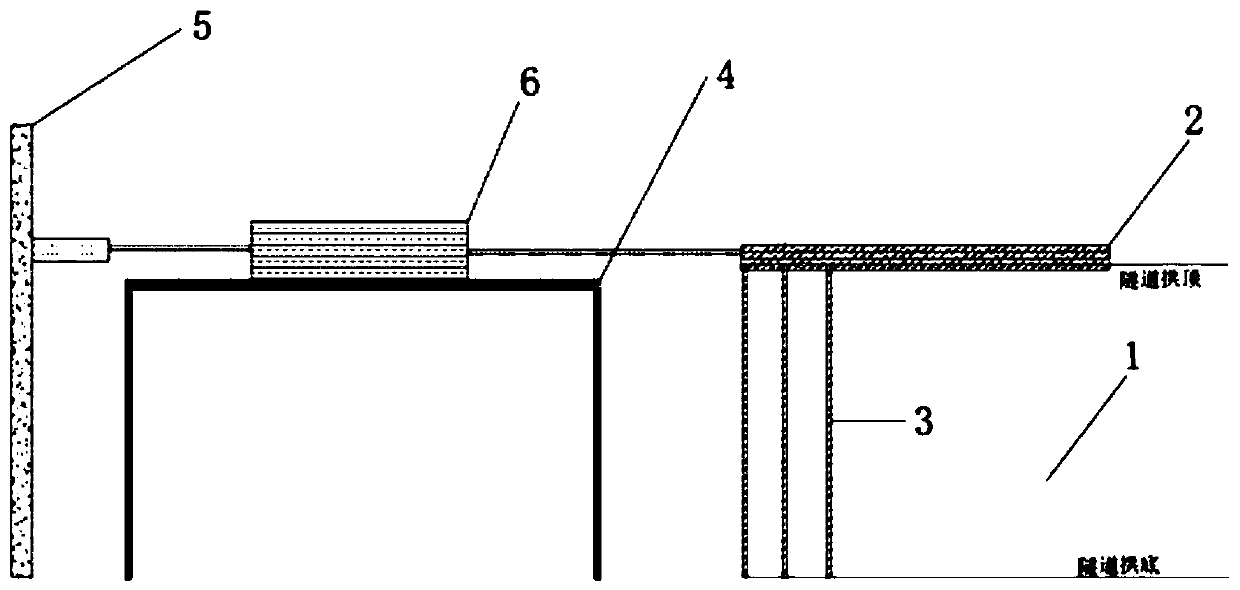

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, the present invention is applicable to the advanced support structure of loose ground, including steel corrugated plate 2 and I-shaped steel frame 3; the steel corrugated plate 2 is driven into the weak surrounding rock 1 of the tunnel through the pusher 5 to form the advanced support, The reinforcement range is at the vault of the tunnel; the I-shaped steel frame 3 is erected under the steel corrugated plate 2 after the tunnel is excavated for a certain distance.

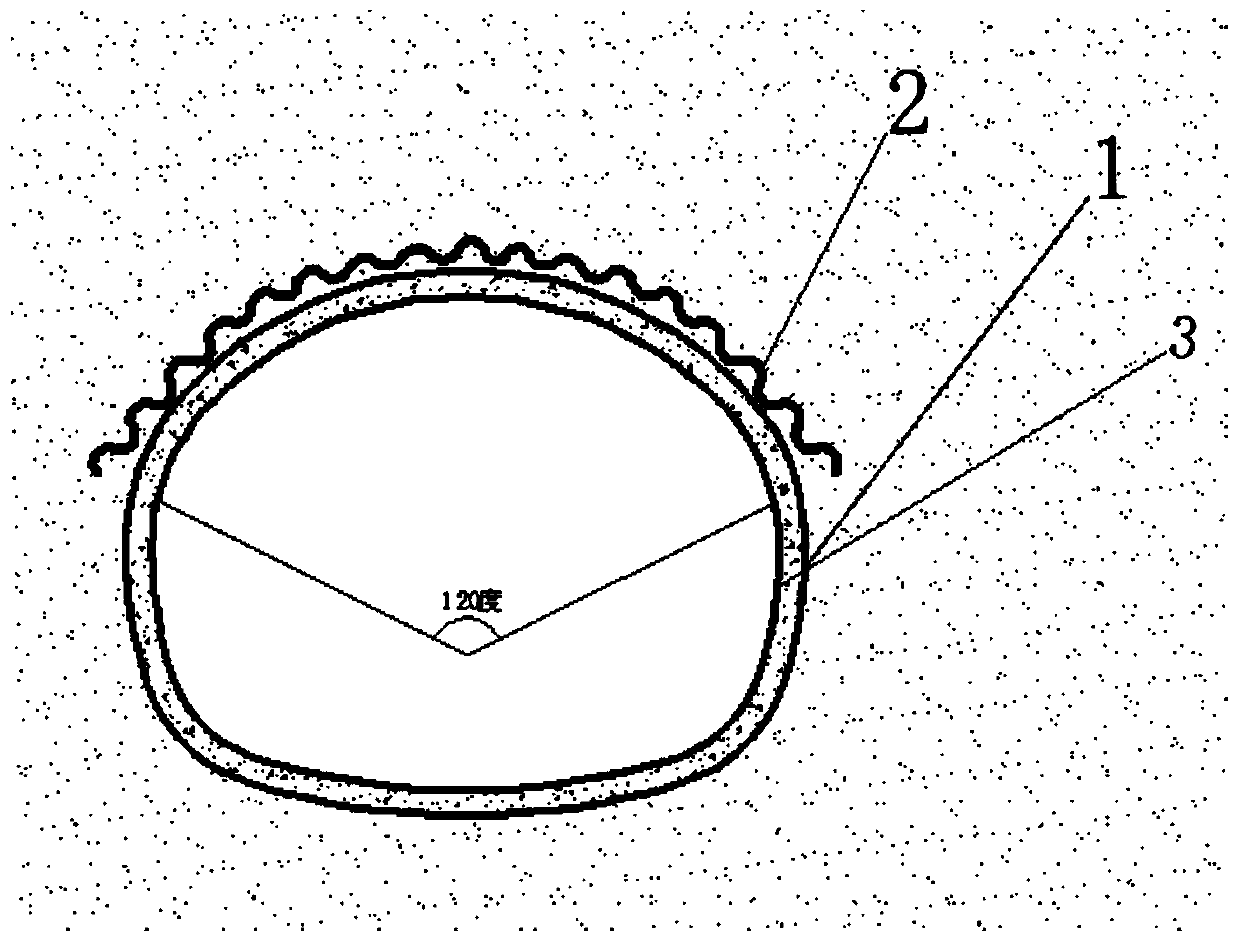

[0025] figure 2 It is a cross-sectional view of the steel corrugated plate. The wall thickness of the steel corrugated plate 2 of the present embodiment is 12mm, the wave pitch is 380mm, and the wave height is 140mm. The reinforcement range is the weak surrounding rock 1 within 120° of the tunnel vault. In addition, the inner and outer surfaces ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap