Buffer protection transmission device and method for shuttle type distribution trolley

A cloth trolley and transmission technology, applied in vibration suppression adjustment, lighting and heating equipment, furnace types, etc., can solve the problems of uncontrollable adjustment of buffer stroke, influence of device operation, etc., to improve rigid force conditions and reduce friction. , reduce the effect of inertial impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

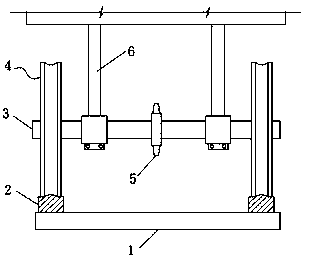

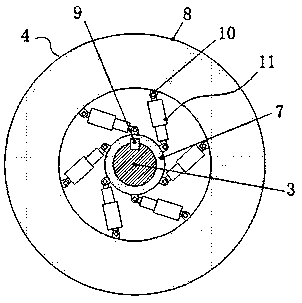

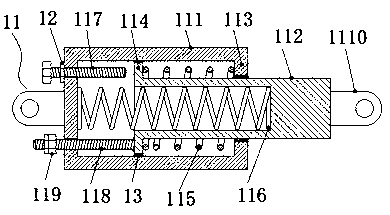

[0033] See Figure 1-3 , The present invention provides a technical solution: a buffer protection transmission device for a shuttle-type distributing trolley, comprising a trolley base 1, a moving track 2, a transmission wheel shaft 3, a roller assembly 4, a transmission sprocket 5 and a trolley frame 6. The moving track 2 is laid symmetrically on the top of the trolley base 1. The roller assembly 4 is arranged at both ends of the drive axle 3. The roller assembly 4 moves along the moving track 2, and the drive sprocket 5 is fixedly sleeved on the middle of the drive axle 3 by a key connection. , The trolley frame 6 is movably installed on the drive axle 3; the roller assembly 4 includes a mounting inner ring 7 and a movable outer ring 8. The inner ring of the mounting inner ring 7 is sleeved with the drive axle 3 and is fixed and driven by the key 9. A buffer device 11 is hinged between the outer part of the ring 7 and the inner wall of the movable outer ring 8 through a hinge...

Embodiment 2

[0038] The embodiment of the present invention provides a buffer protection transmission device for a shuttle-type distributing trolley. On the basis of Embodiment 1, a tightening thin nut 12 is screwed on the constriction screw 117 to play a role of tightening and preventing loosening.

Embodiment 3

[0040] The embodiment of the present invention provides a buffer protection transmission device for a shuttle-type distributing trolley. On the basis of embodiment 1, between the inner edge 113 and the outer wall of the inner sleeve 112 and before the outer flange 114 and the inner wall of the outer sleeve 111 Both are provided with a lubricating seal ring 13, which reduces the resistance of the components and improves the cushioning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com