Fluid distribution valve and fluid treatment device

A fluid distribution valve and fluid channel technology, applied in valve devices, ion exchange processing devices, feeding devices, etc., can solve the problems of high operating cost, high manufacturing difficulty, large inertial force, etc., to simplify equipment structure and reduce manufacturing. The effect of difficulty and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

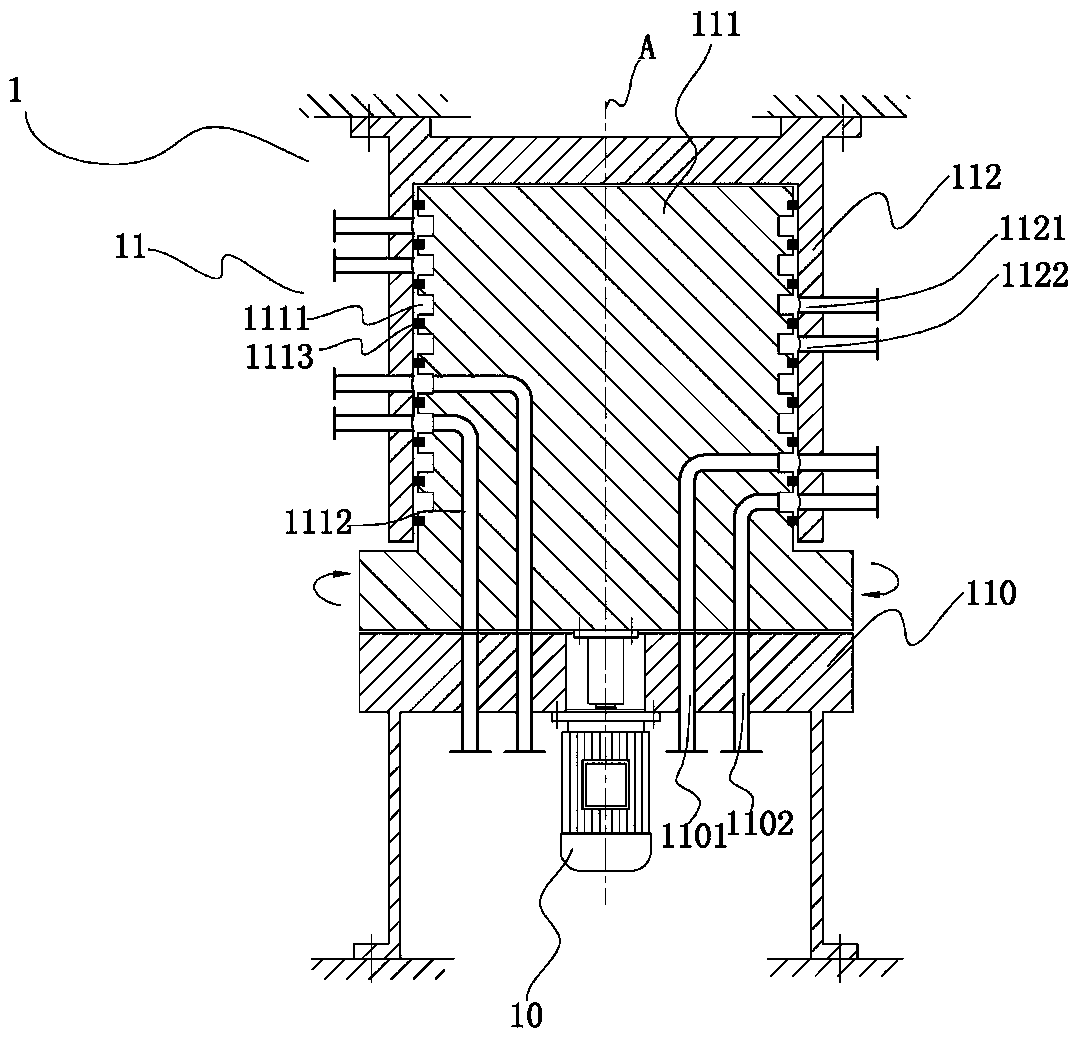

[0021] Such as figure 1 As shown, the fluid dispensing valve 1 of the present invention includes a valve assembly 11 and a transmission device 10;

[0022] Wherein the valve assembly includes a fixed valve disc 110, a rotating valve core 111 and a fixed sleeve 112;

[0023] On the fixed valve disc 110, there are N pairs (N≥2) correspondingly arranged and penetrating the body of the fixed valve disc. Each pair of fluid channels includes a feed fluid channel 1101 and a discharge fluid channel 1102;

[0024] The rotating valve core 111 is arranged on the upper part of the fixed valve disc 110, and is sealedly connected with the fixed sleeve 112 in the fixed sleeve 112 and can rotate around the central axis A; the fixed sleeve 112 is provided with M pairs of feed ports 1121 and outlets. The feed port 1122; the rotary valve core 111 is provided with M pairs of annular flow channels 1111, and the annular flow channels 1111 correspond to and communicate with the feed port 1121 and ...

Embodiment 2

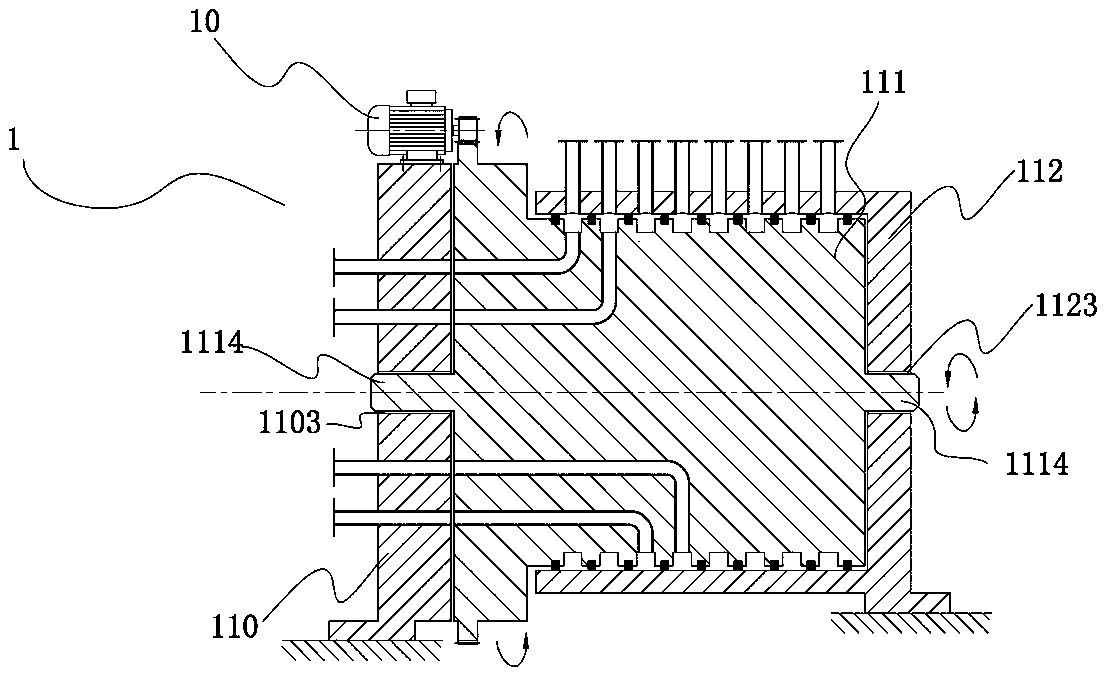

[0026] Such as figure 2 As shown, the difference between it and Embodiment 1 is that the entire fluid distributing valve is arranged horizontally, which is suitable for occasions with a large number of annular flow passages, feed inlets, and discharge outlets (such as vertical, rotary valve cores) will need to be set particularly high), which greatly reduces the height of the equipment. The transmission device 10 is set on the side of the rotary valve core 111 and connected with the rotary valve core 111. The connection method can be conventional chain connection, gear connection, etc., driven by the side The rotary spool 111 rotates. Further, as a preferred mode, recessed parts 1103 and 1123 are provided at the center of the side walls of the fixed valve disc 110 and the fixed sleeve 112, and convex parts 1114 are provided at both ends of the rotary valve core 111, and the convex parts 1114 are arranged in the recessed parts. It is movably connected with the concave part. I...

Embodiment 3

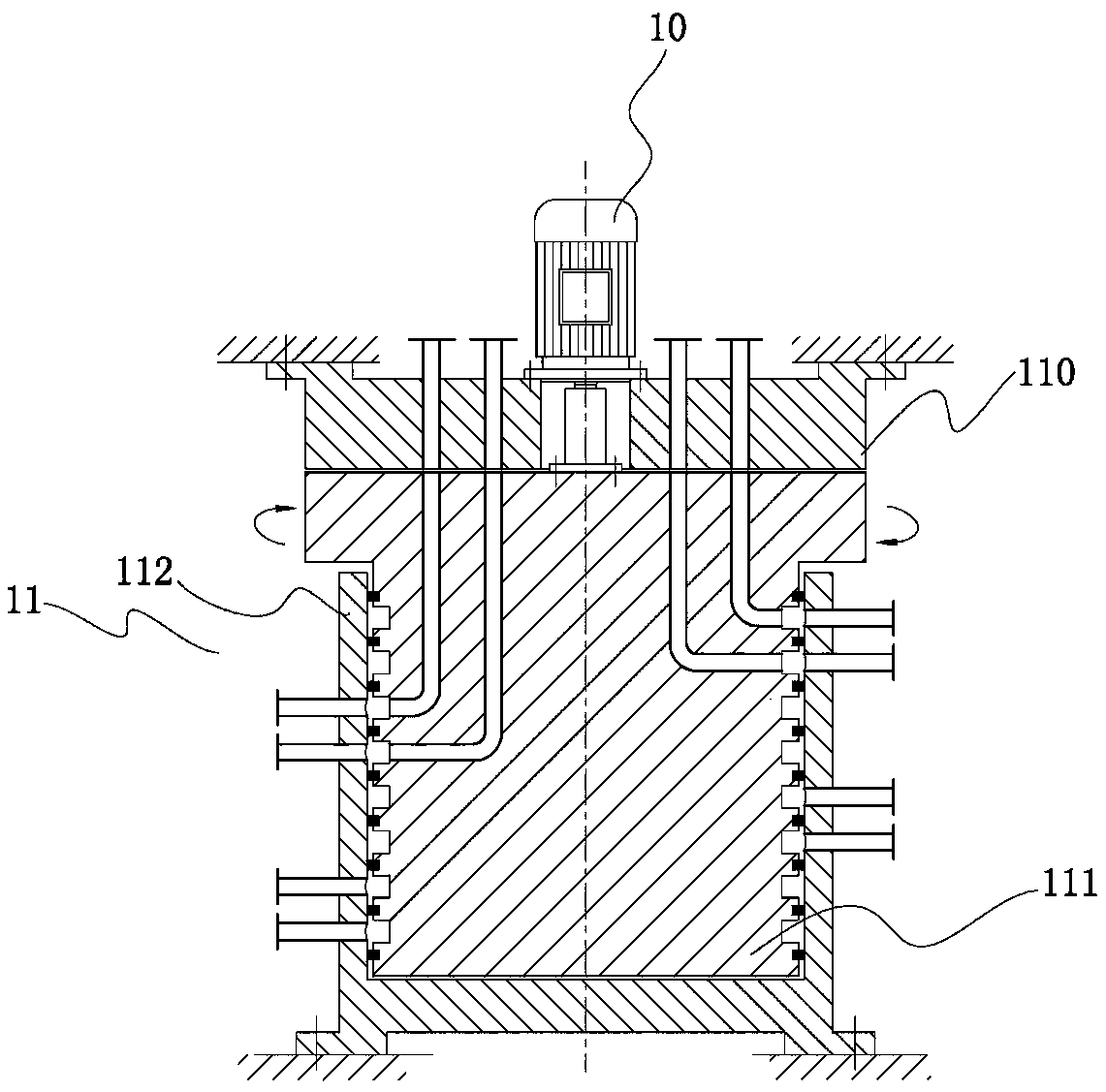

[0028] Such as image 3 As shown, the difference between it and Embodiment 1 is that the rotary valve core 111 is located at the lower part of the fixed valve disc 110, and the purpose of the invention can also be achieved in this way.

[0029] The present invention also includes a fluid treatment device using the above-mentioned fluid dispensing valve, such as Figure 4 As shown, the fluid distribution treatment device of the present invention includes a fluid distribution valve 1 and N reaction vessels 2, and the reaction vessel 2 is provided with a feed liquid inlet 21 and a feed liquid outlet 22, and each pair of fixed valve discs 101 The feed fluid channel 1101 communicates with the feed liquid inlet 21 of the corresponding reaction vessel 2 through a pipeline, and the discharge fluid channel 1102 communicates with the feed liquid outlet 22 of the corresponding reaction vessel 2 through a pipeline.

[0030] In specific use, taking the fluid treatment device applied to ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com