Portable fuze booster tube decomposing machine

A technology of detonator and decomposition machine, which is applied to weapon accessories, ammunition, offensive equipment, etc. It can solve the problems of backward mechanical structure and electrical control system, failure to take fuze detonator accident protection into consideration, and inability to disassemble the fuze detonator. , to achieve the effect of simple and efficient decomposition work, easy maintenance and repair, and enhanced safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

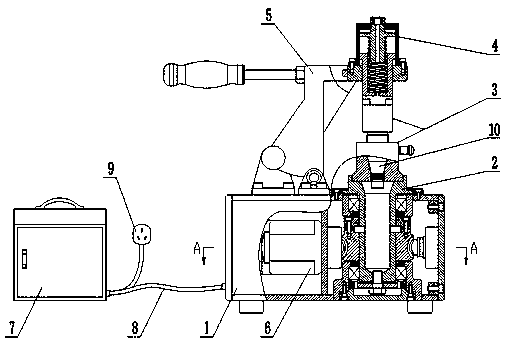

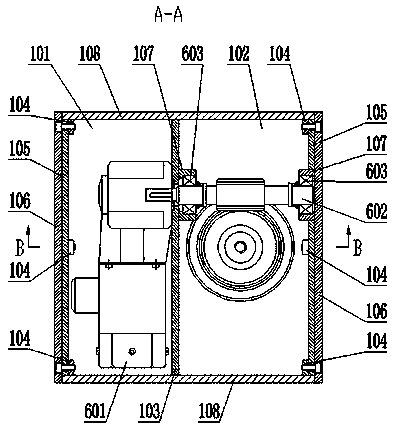

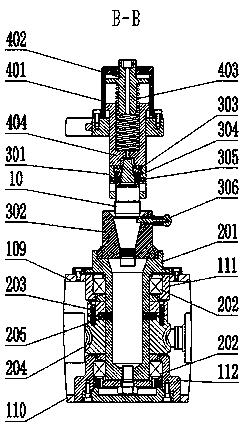

[0053] like figure 1 As shown, a portable fuze detonator decomposition machine of the present invention includes a box body 1, a transmission assembly 2, a fuze element decomposition assembly 3, a pressing device 4, a rotary device 5, a power device 6, a control box 7, a control Cable 8, power cord 9 and fuze element 10. another example figure 2 , image 3 As shown, the box body 1 is a square box body, the box body is provided with an upper panel 109 and a lower panel 110, two left and right panels 106 and two front and rear panels 108 are arranged between the upper panel 109 and the lower panel 110, each left and right panel 106 inboards are also provided with left and right inner baffles 105, and the upper side of the upper panel 109 and the upper side of the lower panel 110 are also welded with mounting blocks 104, and the left and right inner baffles 105 and the left and right panels 106 are installed on the mounting blocks 104 by bolts. The bottom of the box body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com