In-situ device for measuring surface thermal stress of thermal barrier coating system

A technology of thermal barrier coating and thermal stress, which is applied in measuring devices, using stable tension/pressure to test material strength, material thermal analysis, etc., can solve problems such as complex service environment and difficult stress measurement, and achieve simple device structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

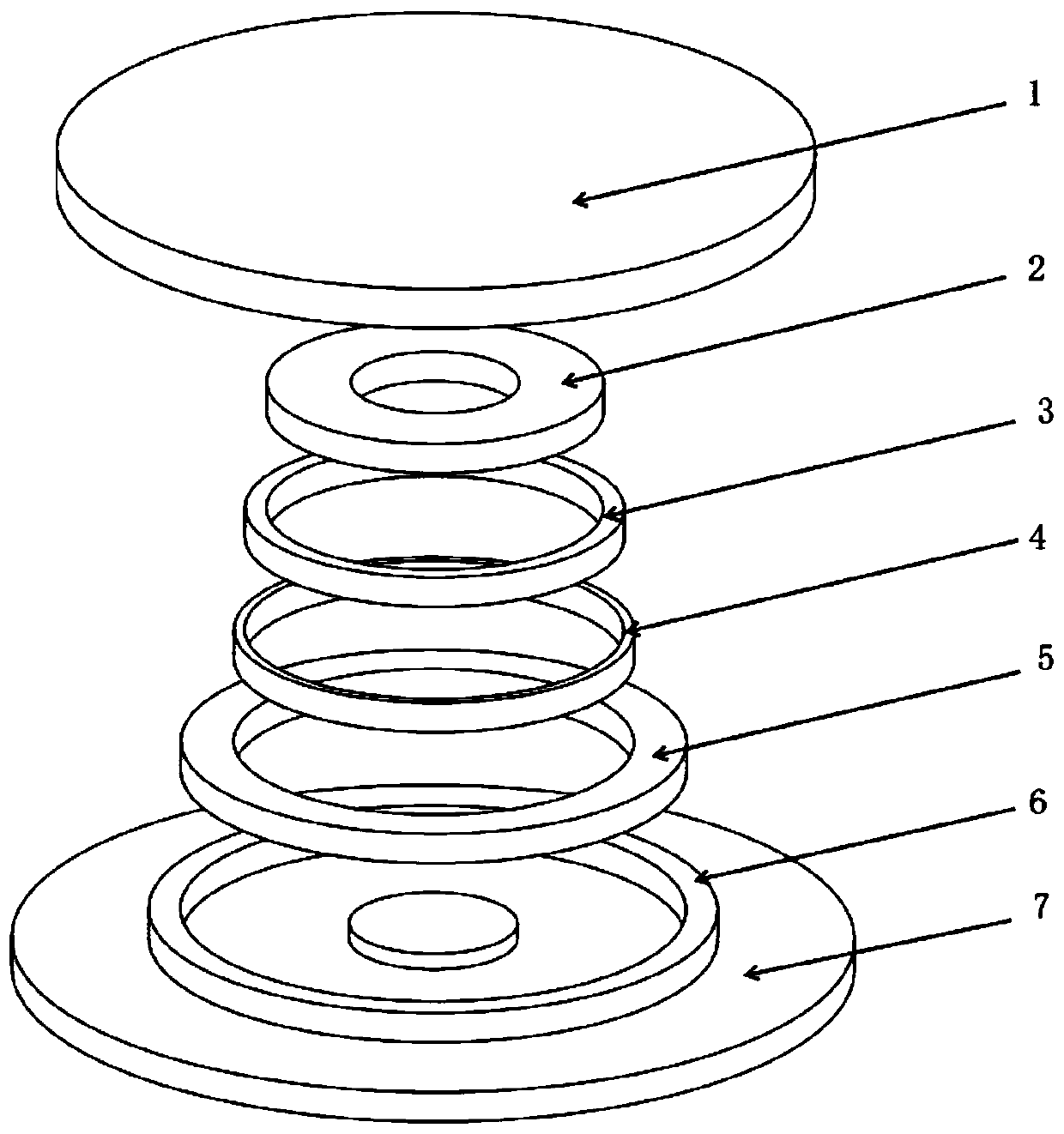

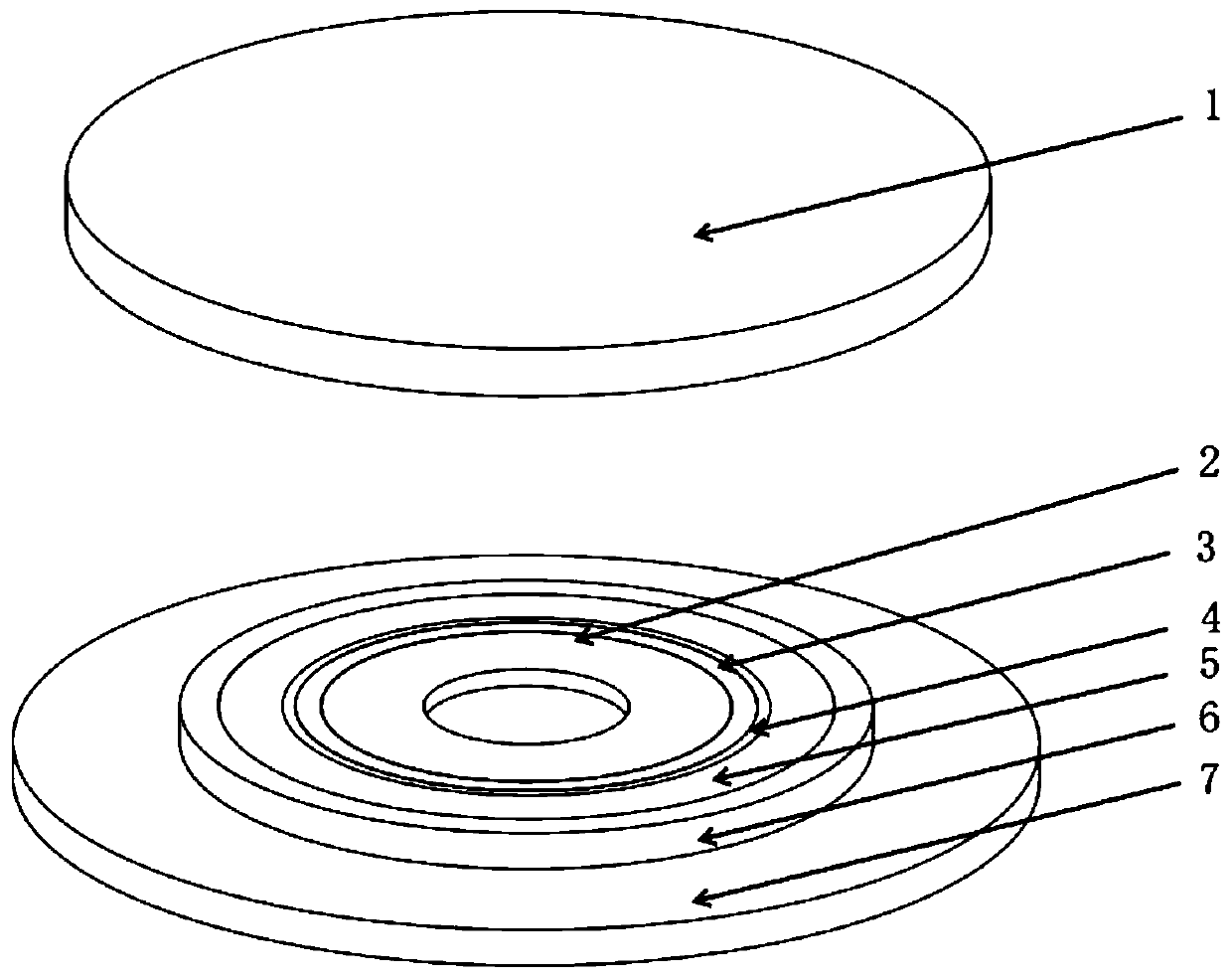

[0018] An in-situ device for measuring the thermal stress on the surface of a thermal barrier coating system, which ensures that the temperature of the thermal barrier coating system can be changed during the thermal stress measurement experiment, and the thermal stress during the heating-heating-cooling process of the sample can be detected without damage . The device includes a stress measuring instrument (101), a substrate (102), an adhesive layer (103), an aluminum oxide film (104), a ceramic layer (105), a heating plate (106) and a fixing plate (107).

[0019] The substrate (102), the bonding layer (103), the aluminum oxide film (104), the ceramic layer (105), and the heating plate (106) are arranged on the fixing plate (107) from inside to outside;

[0020] The stress measuring instrument (101) exists independently above the substrate (102); the outer wall of the substrate (102) is sprayed to form a bonding layer (103); the surface of the bonding layer (103) is sputtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com