Evaluation method for yellowing risk after compounding of PVC artificial leather and PU sponge

A technology of artificial leather and sponge, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

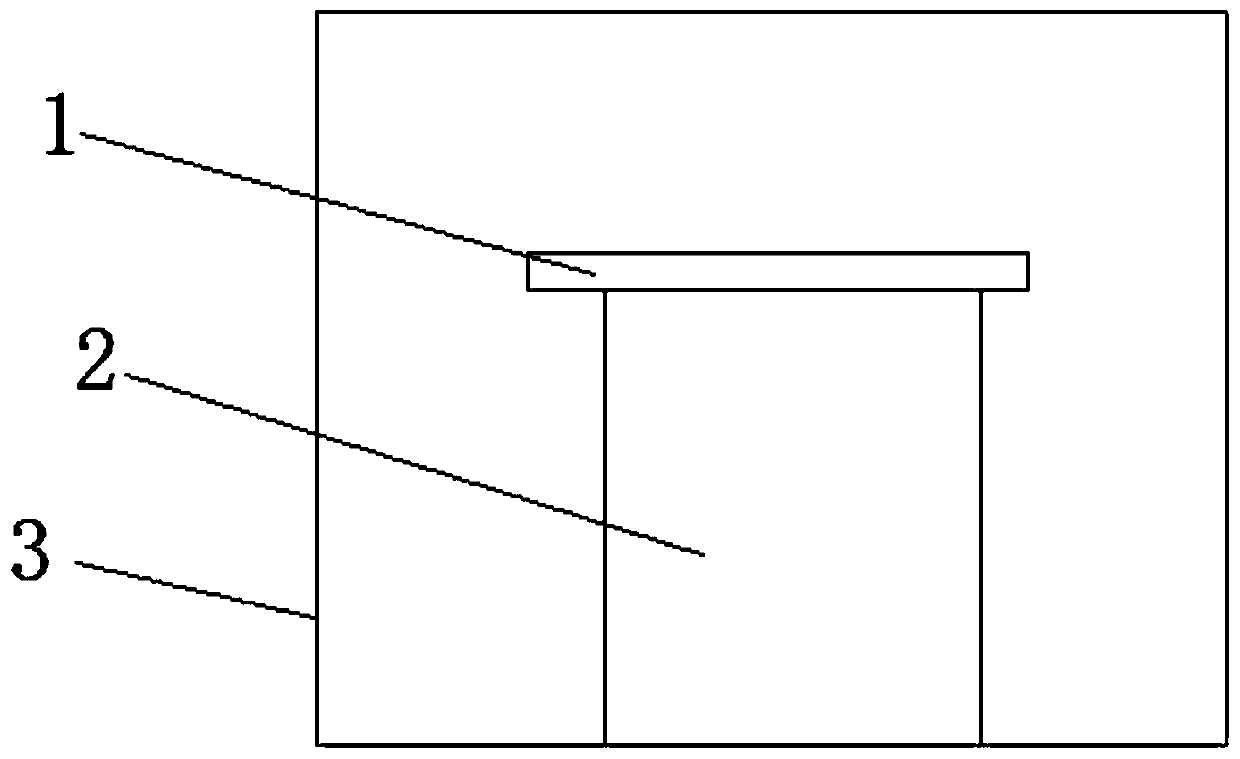

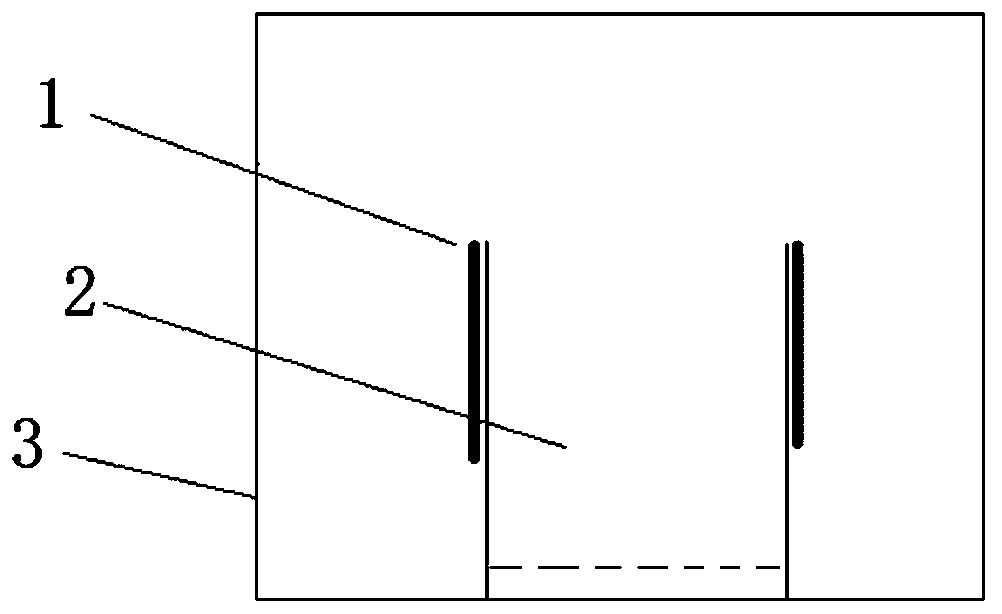

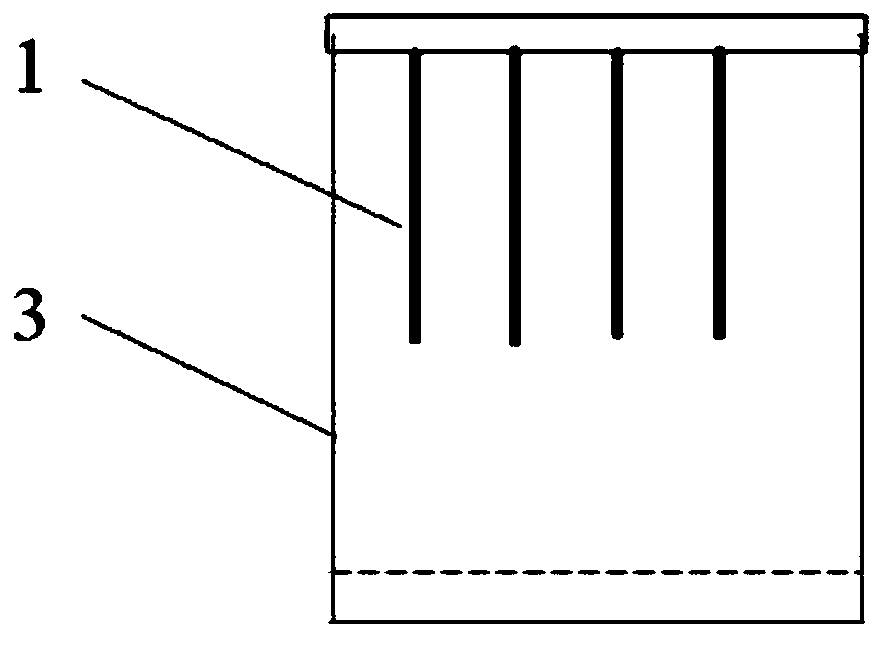

[0085] Take a light-colored PVC sample (STC) and store it in a standard environment for at least 24 hours according to ISO 554-23 / 50, and at least 3 pieces of PVC artificial leather 60*60mm, and then quickly and accurately weigh 500±10mg of 33% triethylene with an analytical balance A solution of diamine in polypropylene glycol (error range ± 2%) was placed in an 80 ml beaker. Cover the prepared PVC sample on the beaker with the PVC side facing up. Then quickly place the beaker with the sample in the middle of a 1000ml odor test glass bottle with a sealed cover, and close the sealed cover, such as figure 1 shown.

[0086] Put the odor test bottle with the test sample in a constant temperature oven at 50°C, take out the PVC sample after standing for 48 hours, wait for the sample to cool to room temperature in a standard environment, and let it stand for 1 hour at room temperature, then use Kone Minolta (KonicMinolta) CM-2500c colorimeter evaluates the color difference before ...

Embodiment 2

[0088] Take a light-colored PVC sample (CRC) and store it in a standard environment for at least 24 hours according to ISO 554-23 / 50, and at least 3 pieces of PVC artificial leather 60*60mm, and then quickly and accurately weigh 500±10mg of 33% triethylene with an analytical balance A solution of diamine in polypropylene glycol (error range ± 2%) was placed in an 80 ml beaker. Cover the prepared PVC sample on the beaker with the PVC side facing up. Then quickly place the beaker with the sample in the middle of a 1000ml odor test glass bottle with a sealed cap, and close the cap. Place the odor test bottle with the test sample in a constant temperature oven at 50°C, take out the PVC sample after standing for 48 hours, and wait for the sample to cool to room temperature in a standard environment. The test instrument, test method, and time are the same as in Example 1. The test results are: ΔL=-0.2, Δa=-0.2, Δb=0.9. The experimental result Δb≤1.0 shows that the risk of yellowin...

Embodiment 3

[0090] Take a light-colored PVC sample (STN) and store it in a standard environment for at least 24 hours according to ISO 554-23 / 50, and at least 3 pieces of PVC artificial leather 60*60mm, and then quickly and accurately weigh 500±10mg of 33% triethylene with an analytical balance A solution of diamine in polypropylene glycol (error range ± 2%) was placed in an 80 ml beaker. Cover the prepared PVC sample on the beaker with the PVC side facing up. Then quickly place the beaker with the sample in the middle of a 1000ml odor test glass bottle with a sealed cap, and close the cap. Put the odor test bottle with the test sample in a constant temperature oven at 50°C, take out the PVC sample after standing for 48 hours, wait for the sample to cool to room temperature in a standard environment, and then measure the values of ΔL, Δa and Δb, test equipment and test The method, time, etc. are the same as in Example 1, and the test results are: ΔL=-0.6, Δa=-0.5, Δb=3.8. The experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com