TBM cutterhead torque determination method and system

A technology of cutter head torque and determination method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as unfavorable hard rock tunnel engineering requirements and complex models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

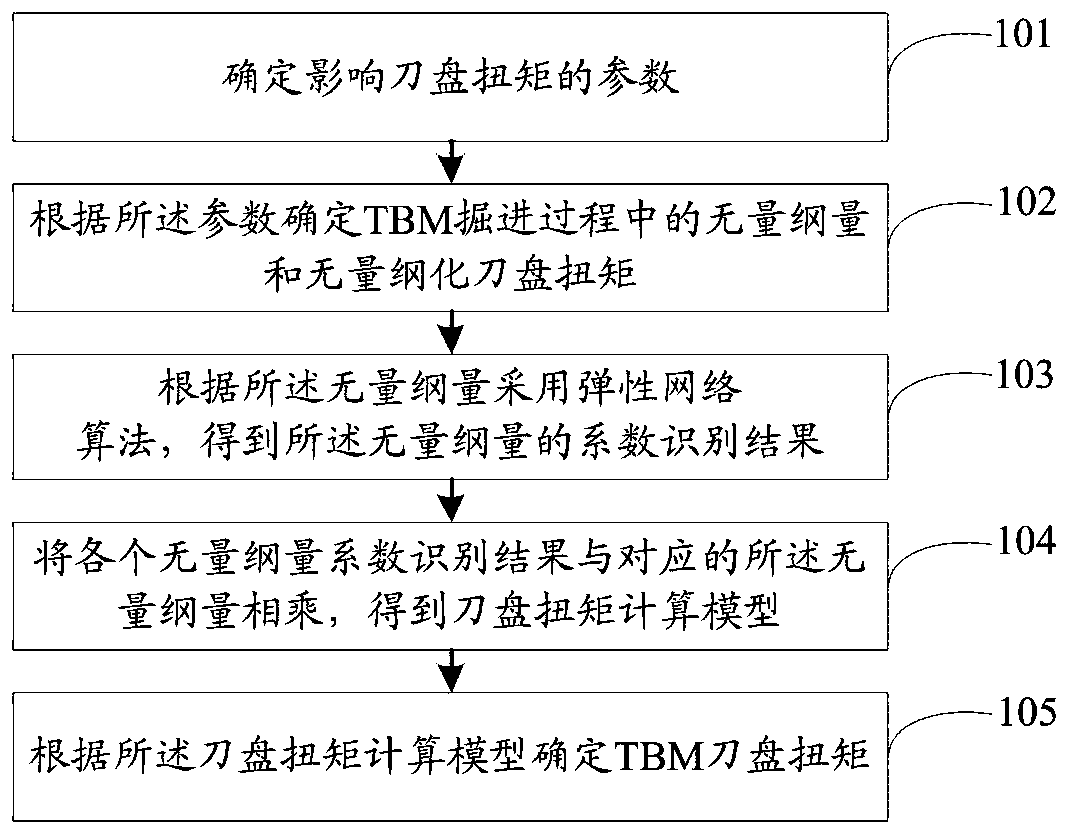

[0078] The calculation method of the cutter head torque of the present invention will be described in detail below in conjunction with the embodiments. Specific steps are as follows:

[0079] 1. List the parameters affecting the torque T of the cutter head: η is the rock firmness coefficient; σ t is the tensile strength of rock, unit: kpa; σ c is the saturated compressive strength of the rock, unit: kpa; f is the friction coefficient of the rock; c is the cohesion of the rock, unit: kpa; V p is rock longitudinal wave velocity, unit: m / s; v is tunneling speed, unit: m / s; ω is cutter head rotation speed, unit: r / min.

[0080] 2. According to the following formulas (1)-(6), calculate the dimensionless quantity and dimensionless cutter head torque respectively. Among them, π 1 , π 2 , π 3 , π 4 , π 5 are five dimensionless quantities; η is the rock firmness coefficient; σ t is the tensile strength of rock, unit: kpa; σ c is the saturated compressive strength of the rock,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com