A high-power DC stabilized power supply for intelligent drilling tools

A technology of DC stabilized power supply and drilling tools, which is applied in the direction of converting DC power input to DC power output, converting AC power input to DC power output, and converting AC power input to AC power output, etc., which can solve the limitation of battery power supply mode Capacity and volume, single power supply module is difficult to meet high-power power supply demand, load balancing problem is difficult to solve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0033] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

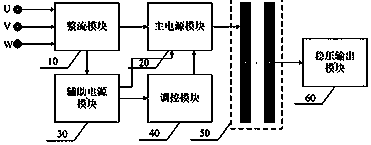

[0034] Such as figure 1 Shown is a high-power DC stabilized power supply for smart drilling tools, including a rectifier module 10, a main power module 20, an auxiliary power module 30, a control module 40, a high frequency inverter module 50, and a stabilized output module 60. Wherein, the rectifier module 10 is connected to the main power module 20 and the auxiliary power module 30, the auxiliary power module 30 is connected to the main power module 20 and the control module 40, and the main power module 20 is connected to the The high-frequency inverter module 50 is connected to the regulated output module 60. The rectifier module 10 is used to convert the three-phase AC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com