Automatic spiral press and forging and pressing method thereof

A screw press and forging technology, which is applied in the field of automatic screw press and forging, can solve the problems of hidden dangers of workers, inaccurate assembly, increased workload of workers, etc., and achieve the effect of reducing workload and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

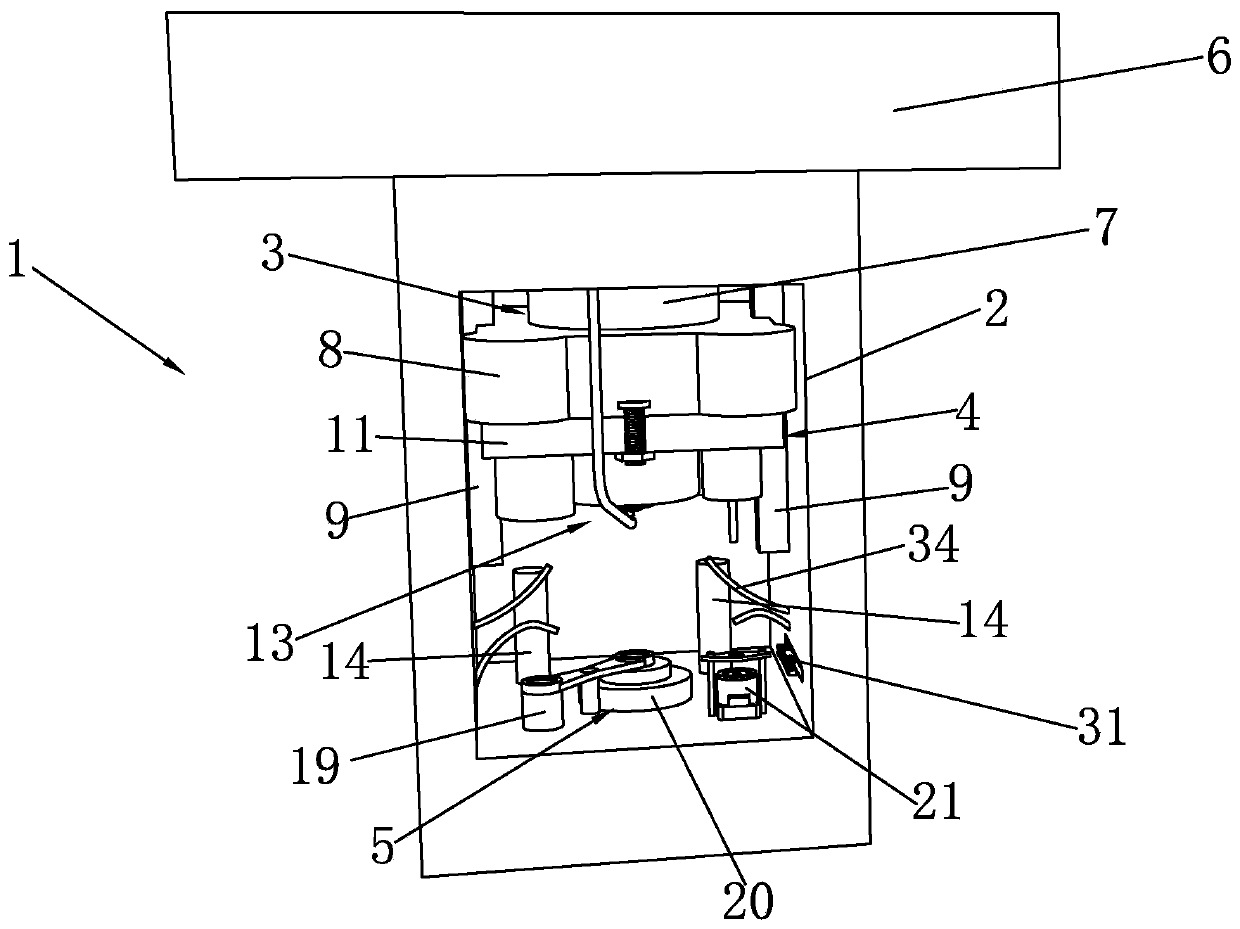

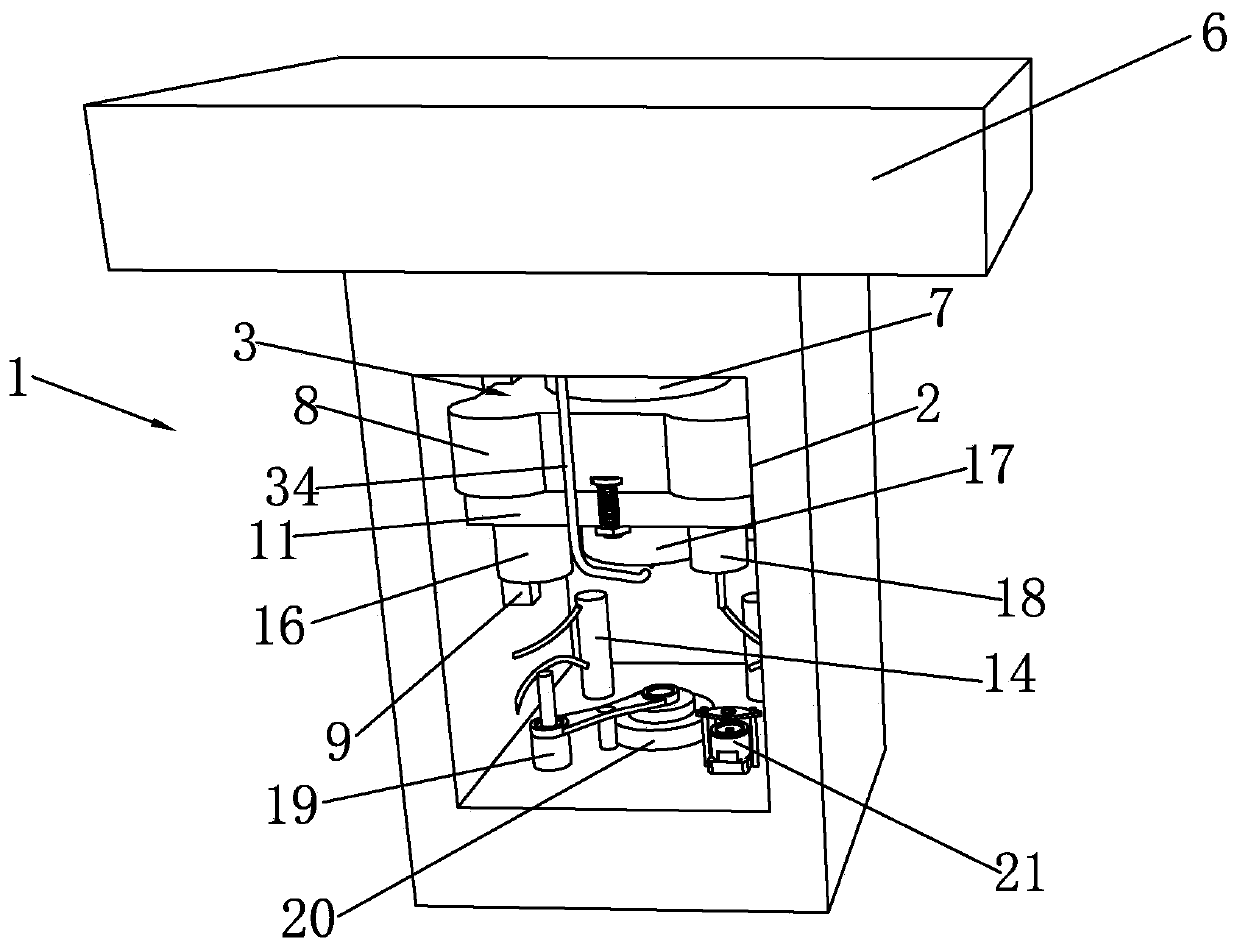

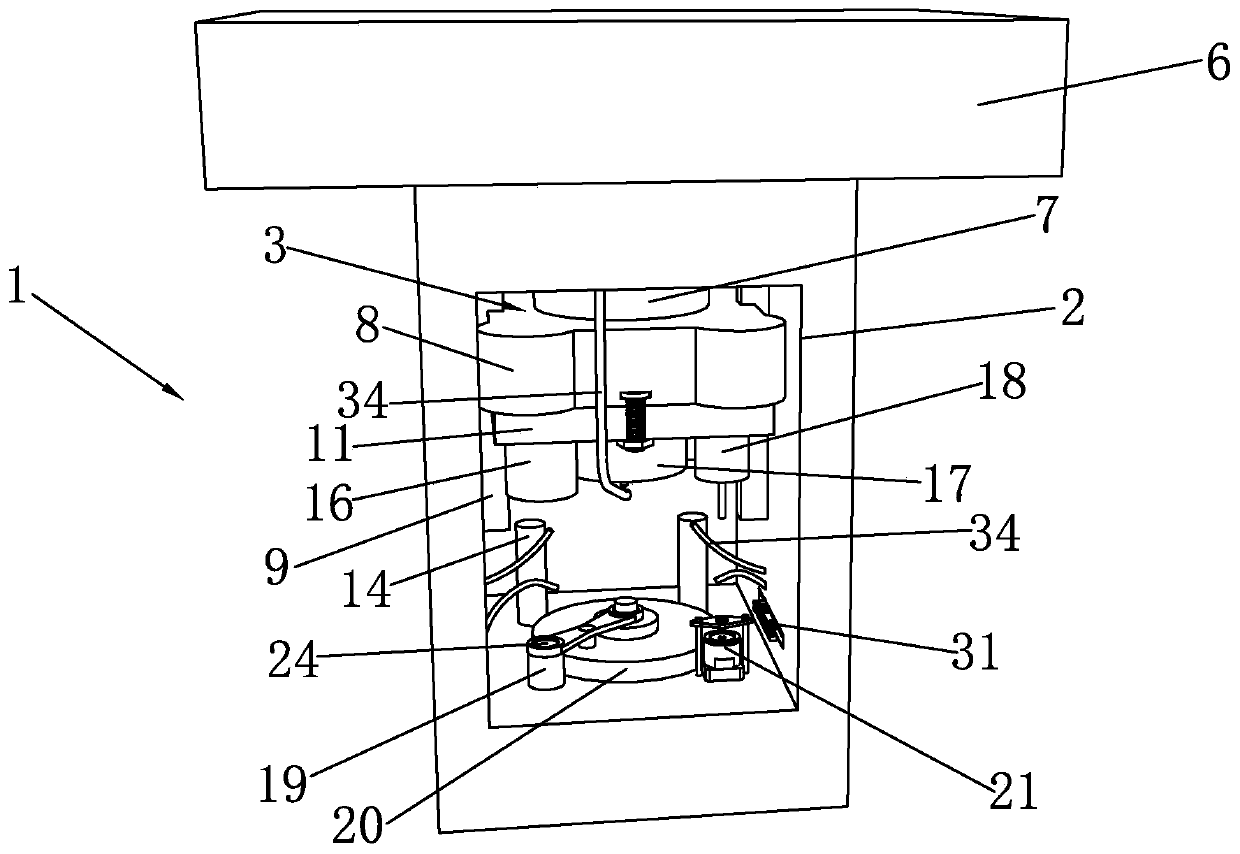

[0053] Such as figure 1 , Figure 6 to Figure 9 As shown, it is an automatic screw press of the present invention, including a body 1, the body 1 is provided with a forging port 2, and the top of the forging port 2 is provided with a spiral forging mechanism 3, and the spiral forging mechanism 3 passes through the top of the forging port 2.

[0054] The bottom of the spiral forging mechanism 3 is fixedly connected with a stamping die frame mechanism 4, and the stamping die frame mechanism 4 is located in the forging mouth 2, and the inner bottom of the forging port 2 is fixedly connected with a forging table assembly 5, and the forging table assembly 5 and the stamping die frame mechanism 4 are matched, and an automatic assembly mechanism is provided in the forging mouth 2, and the automatic assembly mechanism matches the forging table assembly 5.

[0055] The spiral forging mechanism 3 includes a transmission box 6, a screw 7 and a slider 8. The transmission box 6 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com