Micro laser precision machining device

A precision machining and laser technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of effectively processing small processing surfaces with small thickness, inaccurate processing positioning, difficult system assembly and adjustment, etc., to achieve flatness adaptation The effect of strong performance, long processing distance and large dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

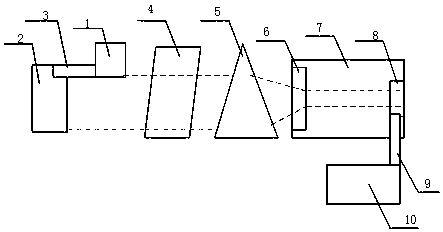

[0012] Such as figure 1 As shown, a micro-laser precision machining device includes a laser 1, a visible light source 2, a plane mirror 3, a beam expander collimator 4, an axicon prism 5, an optical window 6, a pressure fluid chamber 7 and a nozzle microhole 8, and a plane mirror 3 Located in front of the laser 1 and the visible light source 2, the laser beam emitted by the laser 1 is coupled with the beam of the visible light source 2 through the plane mirror 3, the beam expander collimator 4 is located in front of the plane mirror 3, the axicon 5 is located in front of the beam expander collimator 4, and the pressure fluid The cavity 7 is located in front of the axicon 5, the optical window 6 is located at the top of the pressure fluid cavity 7, the nozzle microhole 8 is located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com