Production line for metal bracket preparation

A production line and metal technology, which is applied in the field of metal bracket preparation production line, can solve the problems of insufficient fixing precision, influence on production efficiency and quality, and decline in production and processing quality, and achieve the effects of improving production efficiency, good stability, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

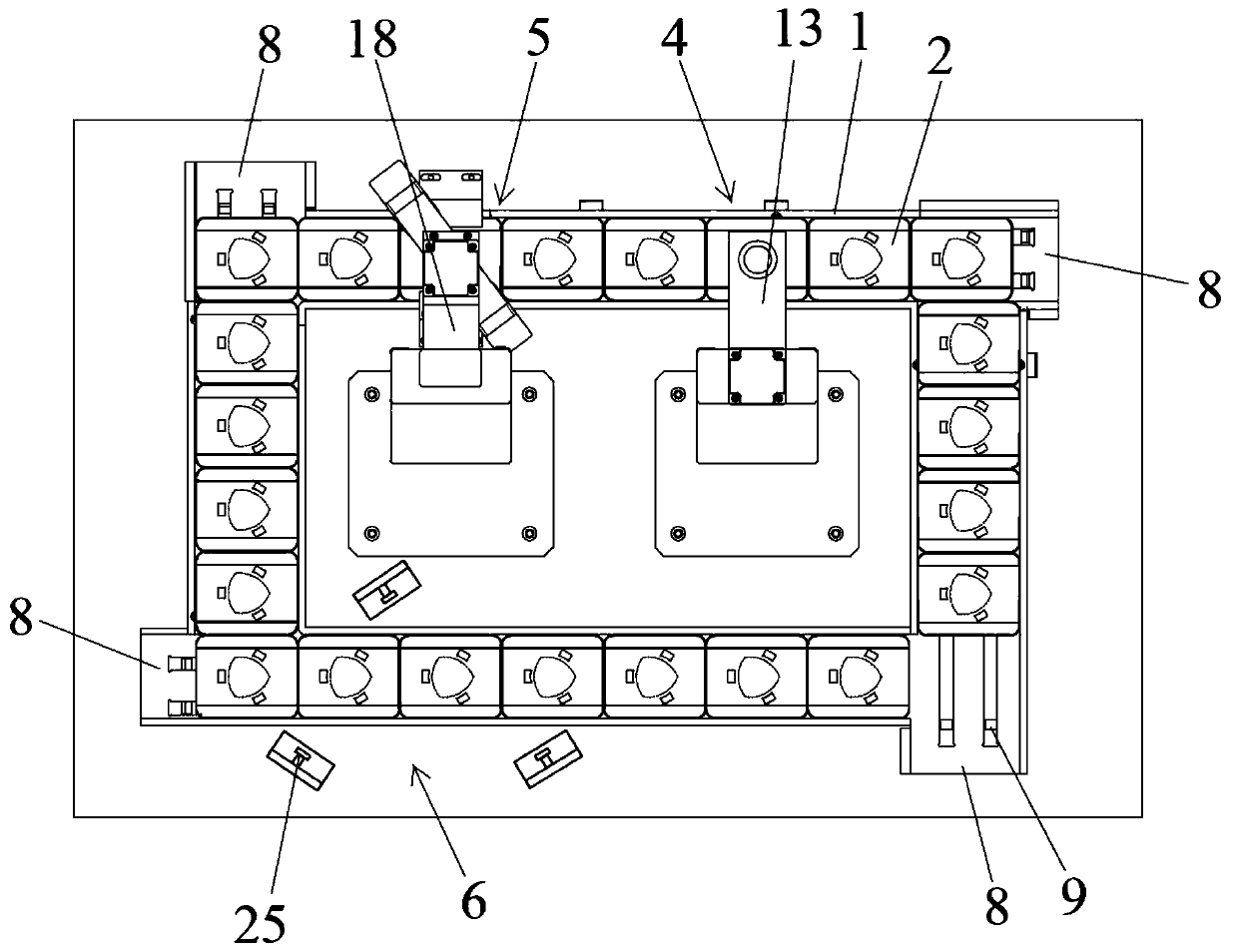

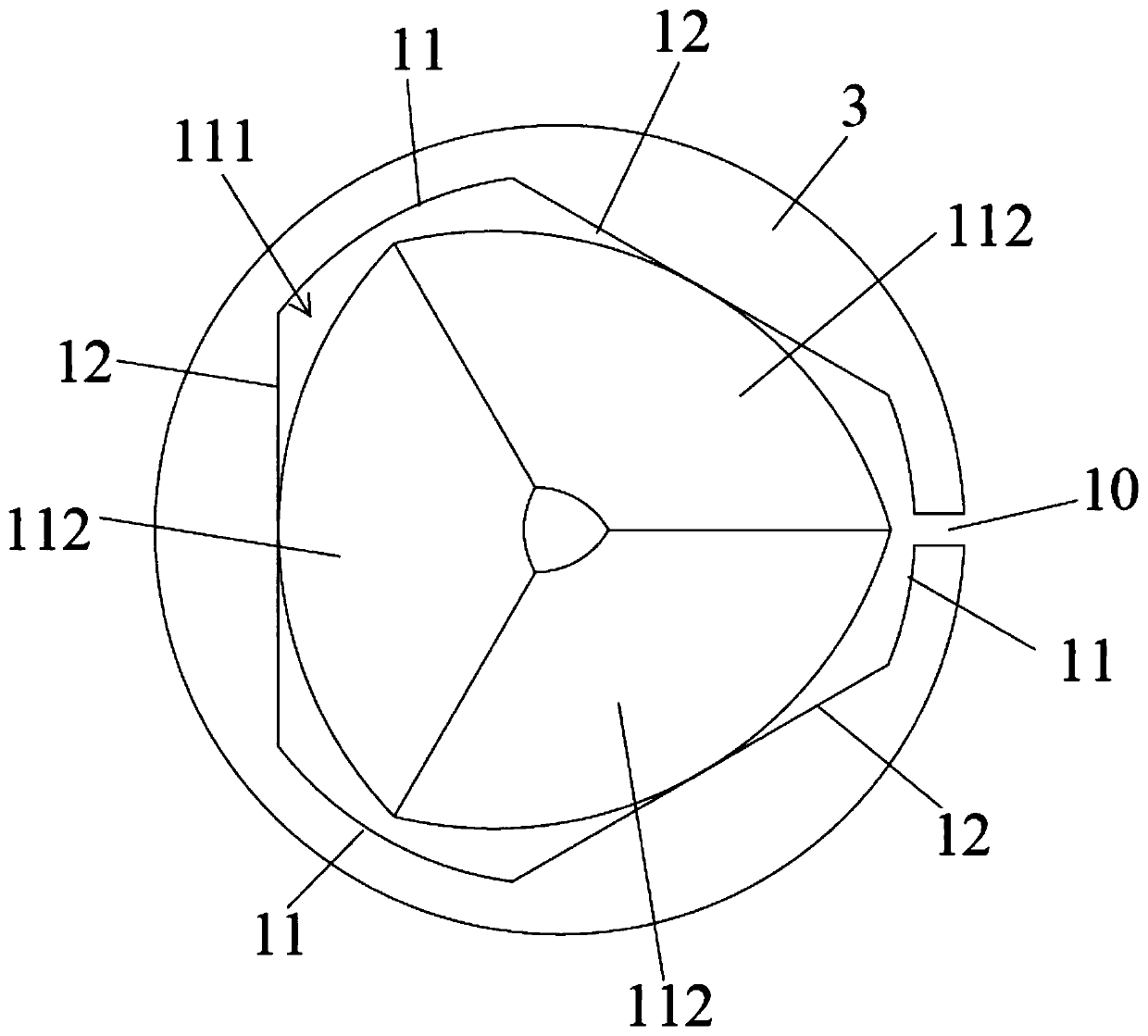

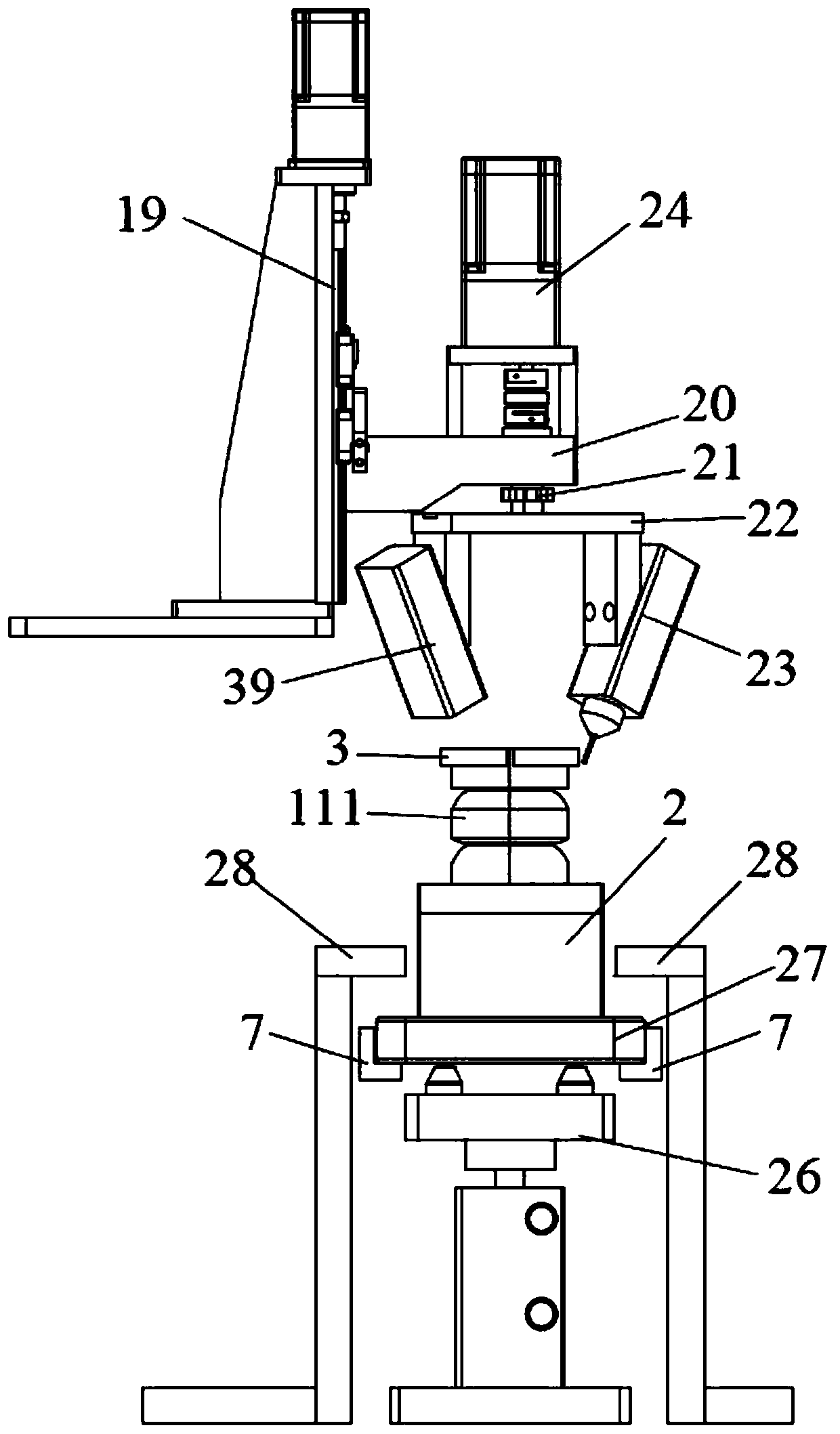

[0033] refer to Figure 1 to Figure 8 As shown, an embodiment of the metal bracket production line of the present invention includes a back-shaped flow conveying line 1, and a plurality of three-claw fixtures 2 are arranged on the back-shaped flow conveying line, and the three-claw fixture is an existing fixed structure , through the way of rotation, the clamping and releasing effects can be realized; the three-claw jig is used to clamp and fix the bottom of the bracket 111, the bracket is composed of a three-petal combination block 112, and the top is also provided with a C-shaped metal clip 3, which is back-shaped Along the conveying direction, the flow conveying line is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com