A kind of automobile door headway sealing strip

A technology for sealing strips and car doors, which is applied to sealing devices, engine seals, vehicle components, etc. It can solve the problems of shortening the service life of sealing strips, affecting the degree of sealing, and being easy to install and not in place, so as to achieve good extrusion resistance and prolong Service life, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

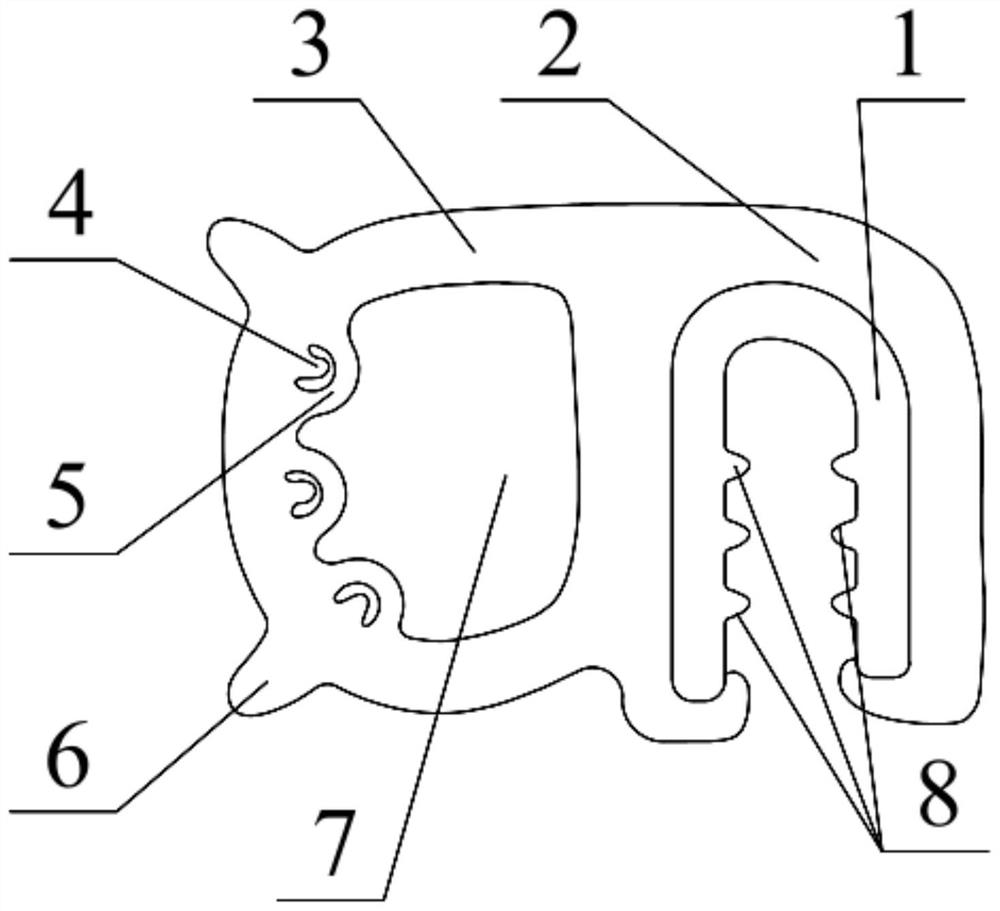

[0029] A door seal strip for automobiles, comprising a sealing part and a fixing part, the sealing part is a sponge foam tube 3, the fixing part includes a PVC rubber base 1 and a modified ethylene-propylene rubber base 2, and the modified ethylene-propylene rubber base 2 The propylene rubber matrix 2 and the sponge foam tube 3 are an integral extruded structure, the PVC rubber base 1 is in an inverted U-shaped structure, and installation teeth 8 are arranged on the inner side of the U-shaped groove, and the installation teeth 8 are PVC rubber bases 1. An elastic structure protruding into the U-shaped groove. The modified ethylene-propylene rubber matrix 2 is arranged on the outside of the PVC rubber substrate 1. The sponge foam tub...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap