Double-end-sealed reciprocating type high-speed pillow packing machine and packing technology thereof

A pillow packing machine and duplex technology, which is applied in the field of pillow packing machines, can solve the problems of low production efficiency, achieve the effect of convenient feeding, reduce the volume of the tool holder, and reduce the radius of gyration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

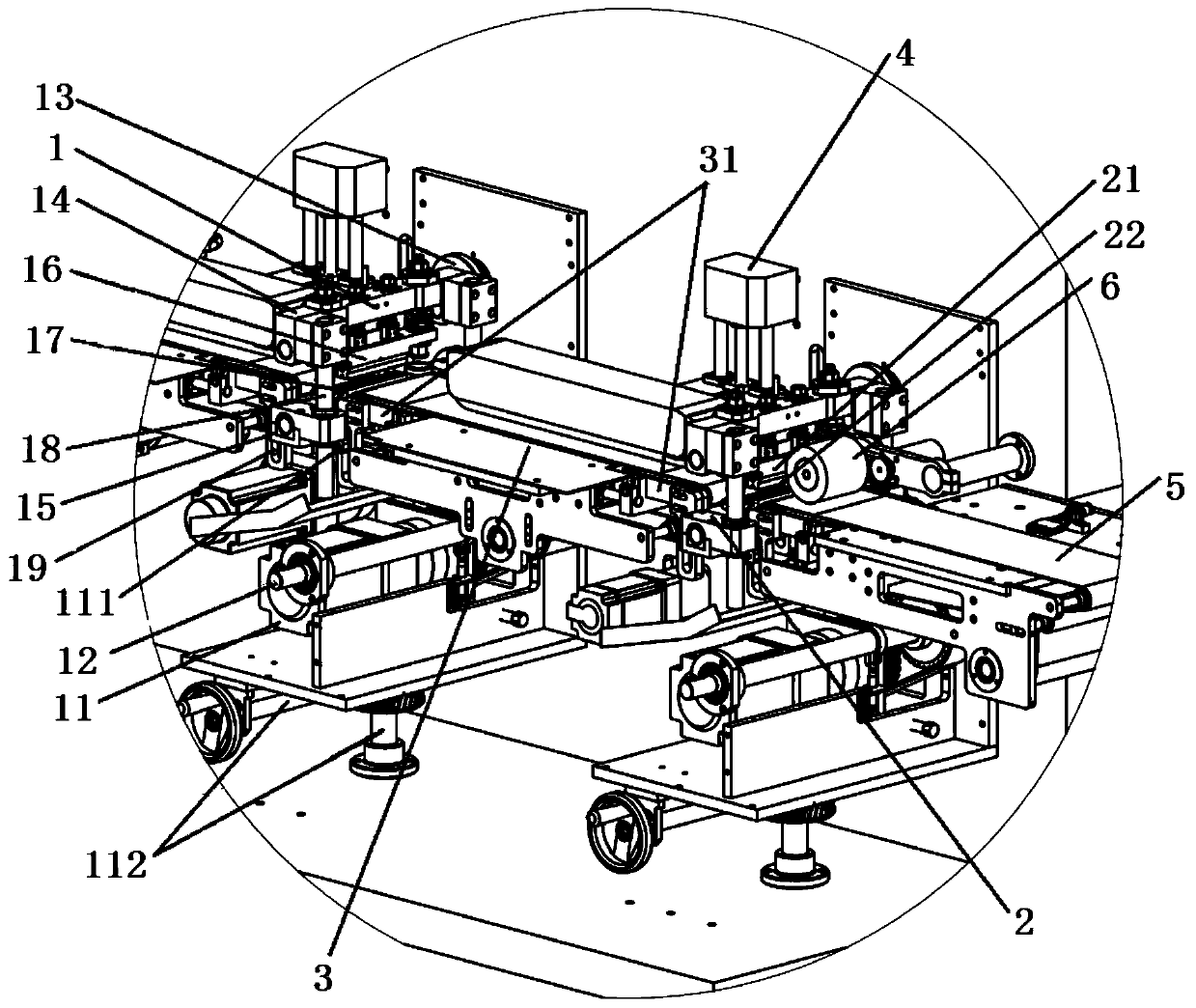

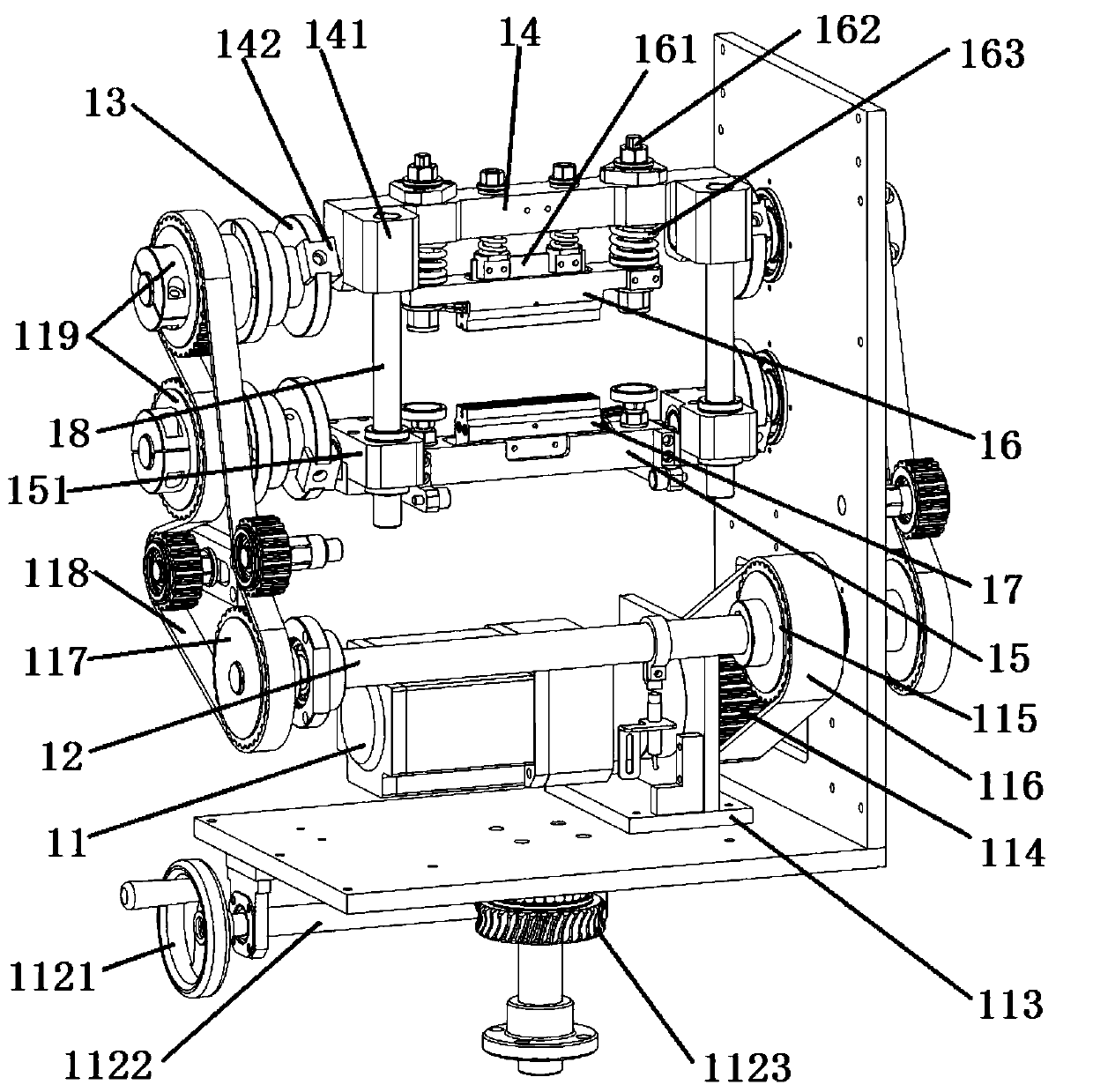

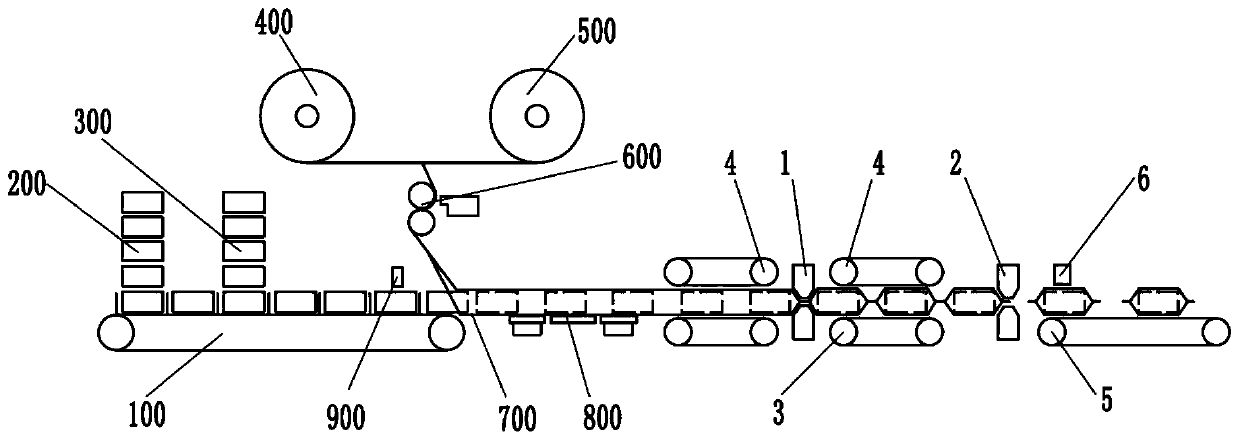

[0032] Refer below Figure 1 to Figure 3 To further explain this application, such as figure 1 and image 3 A double-end sealing reciprocating high-speed pillow packing machine is shown, including a frame, a feeding device 100, a film forming bag making device 700, a middle sealing device 800, an end sealing preheating device 1, an end sealing heat cutting device 2, a transition Conveying device 3, a pair of upper pressing device 4, discharging conveying device 5 and discharging brushing device 6, the top of described feeding device 100 is provided with feeding device 200, replenishing device 300 and material anomaly detecting device 900, described The feeding device 300 is located between the feeding device 200 and the material abnormality detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com