A kind of light-weight and high-strength exterior wall interior thermal insulation gypsum and preparation method thereof

A high-strength, external wall technology, applied in the field of building insulation materials, can solve the problems of the contradiction between the strength and density of thermal insulation gypsum in the external wall, the contradiction between thermal insulation and workability, and poor smearability, etc., to achieve good retarding effect, high Strength and compactness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

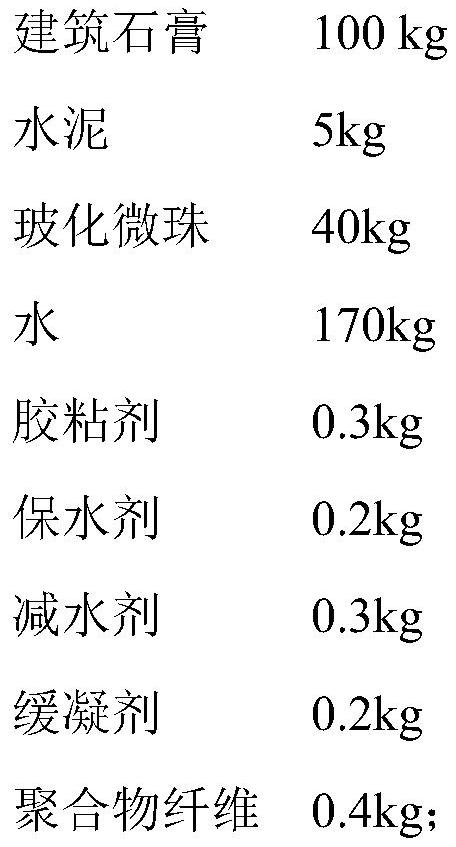

[0031] A light-weight and high-strength thermal insulation gypsum for exterior walls, taking 100kg of building gypsum as an example, the raw materials and their quality are as follows:

[0032]

[0033] Among them: the particle size of the above-mentioned building gypsum is 45 μm to 145 μm, and the mass ratio of the particles distributed in the two intervals of 45 μm to 80 μm and 80 μm to 145 μm is 40:60;

[0034] The cement is grade 42.5 sulfoaluminate cement, the particle size is less than 45 μm, and the mass ratio of the particles distributed in the two intervals of <15 μm and 15 μm to 45 μm is 60:40;

[0035] The particle size of vitrified microbeads is 145 μm to 250 μm, and the mass ratio of particles distributed in the two intervals of 145 μm to 180 μm and 180 μm to 250 μm is 35:65;

[0036] The present invention optimizes the particle gradation of cementitious materials such as building gypsum, cement, and vitrified microbead light aggregates as a whole, and realizes...

Embodiment 2

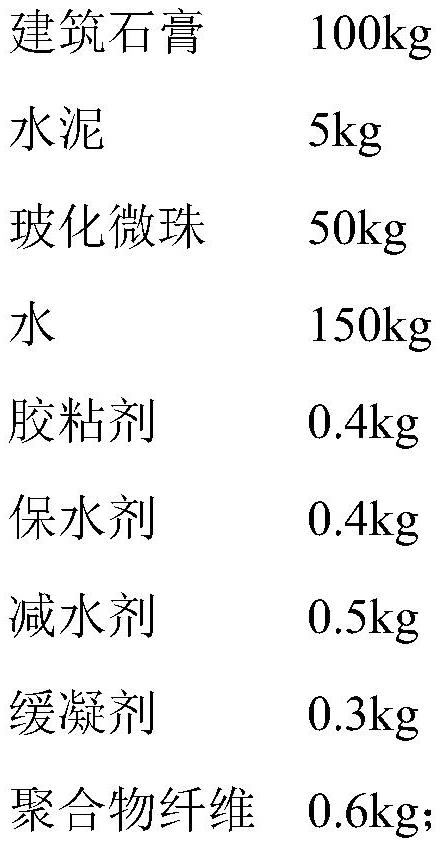

[0047] A light-weight and high-strength thermal insulation gypsum for exterior walls, taking 100kg of building gypsum as an example, the raw materials and their quality are as follows:

[0048]

[0049] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

Embodiment 3

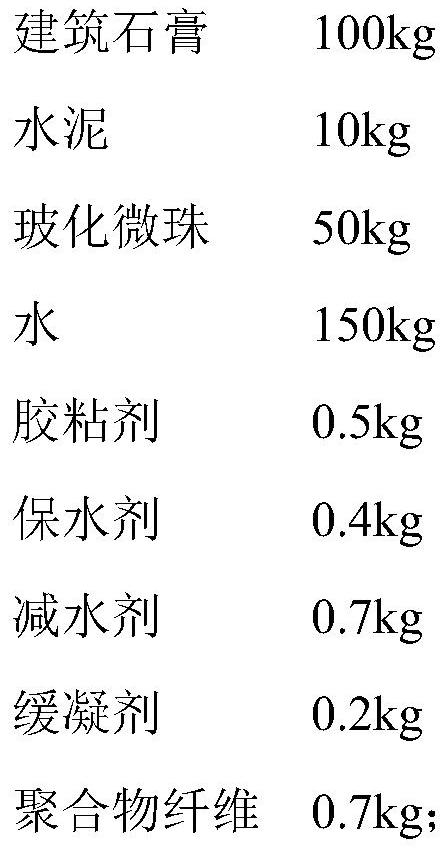

[0051] A light-weight and high-strength thermal insulation gypsum for exterior walls, taking 100kg of building gypsum as an example, the raw materials and their quality are as follows:

[0052]

[0053] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com