Patents

Literature

32results about How to "Avoid excessive losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

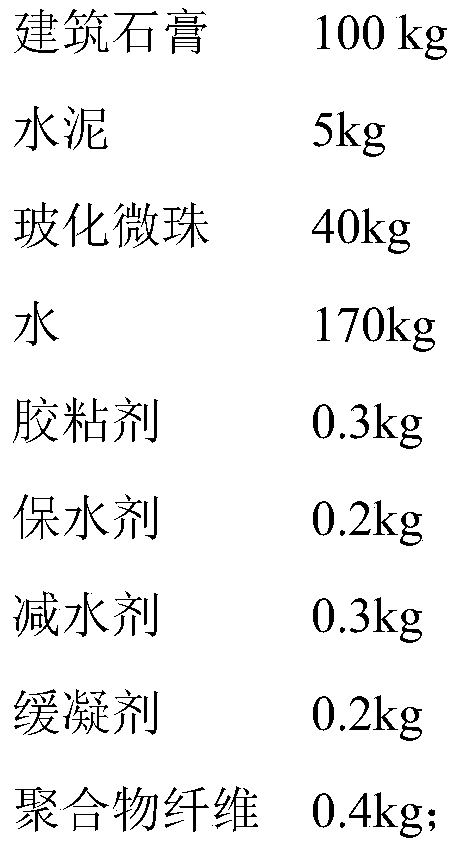

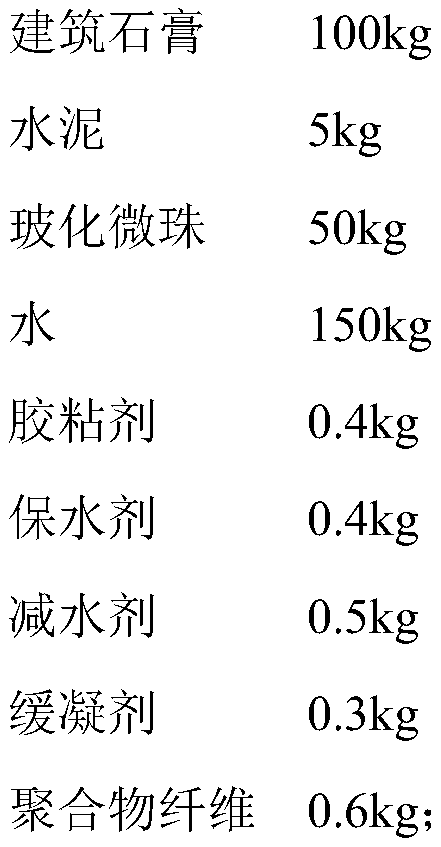

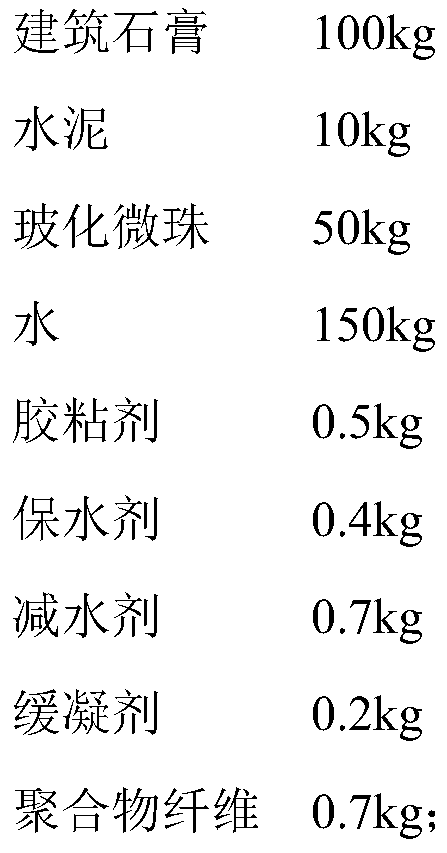

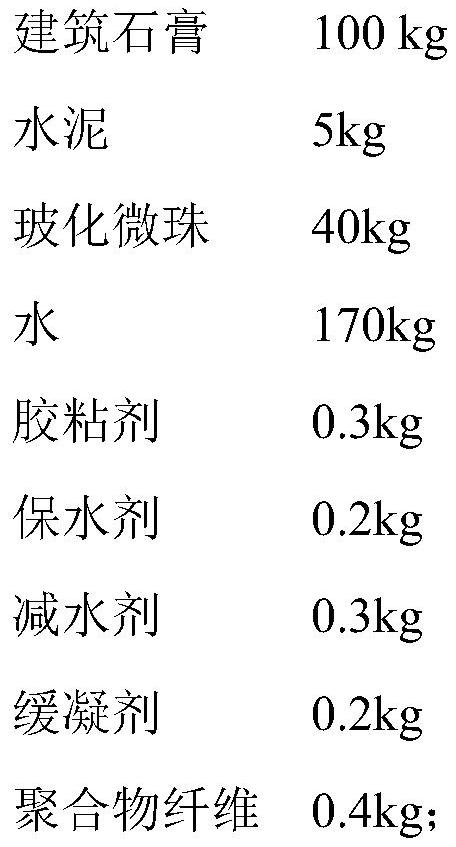

Light high-strength external wall inner thermal gypsum and preparing method thereof

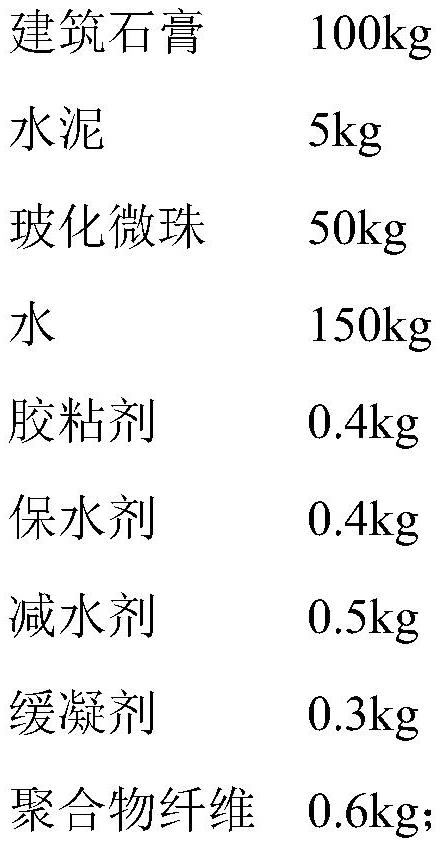

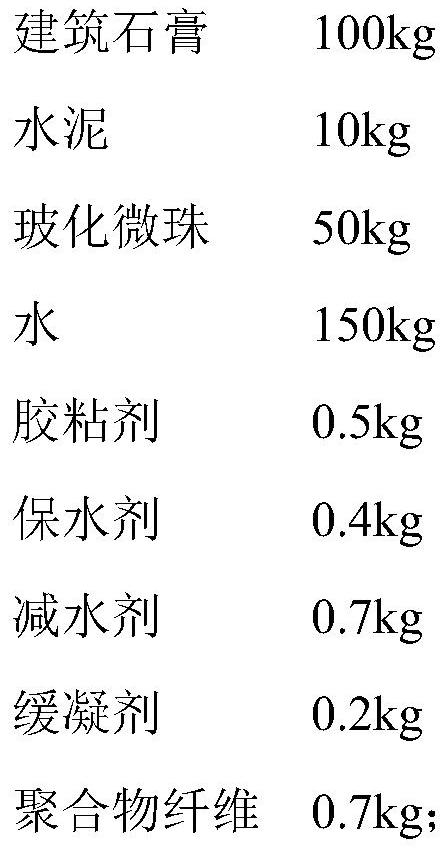

The invention relates to light high-strength external wall inner thermal gypsum. The external wall inner thermal gypsum is prepared from, by mass, 100 parts of building plaster, 5-15 parts of cement,40-60 parts of glass beads, 120-170 parts of water, 0.2-0.6 part of an adhesive, 0.2-0.5 part of a water-retaining agent, 0.3-0.9 part of a water reducing agent, 0.2-0.5 part of a retarder and 0.4-1.2parts of polymer fiber. The overall particle grading optimization, the water reducing agent and the like are adopted for reducing the water demand under the standard working thickness, the reinforcing and modifying treatment is conducted on the external wall inner thermal gypsum through various measures of increasing hydration products through the cement, compounding the retarder and the like, and the prepared light high-strength external wall inner thermal gypsum has excellent thermal insulation performance, can greatly reduce the operation energy consumption of a building, and meanwhile hashigh strength. The strength problem and workability problem of the thermal gypsum on the basis of low density and good thermal insulation performance are solved.

Owner:CHONGQING JIANDA BUILDING MATERIAL

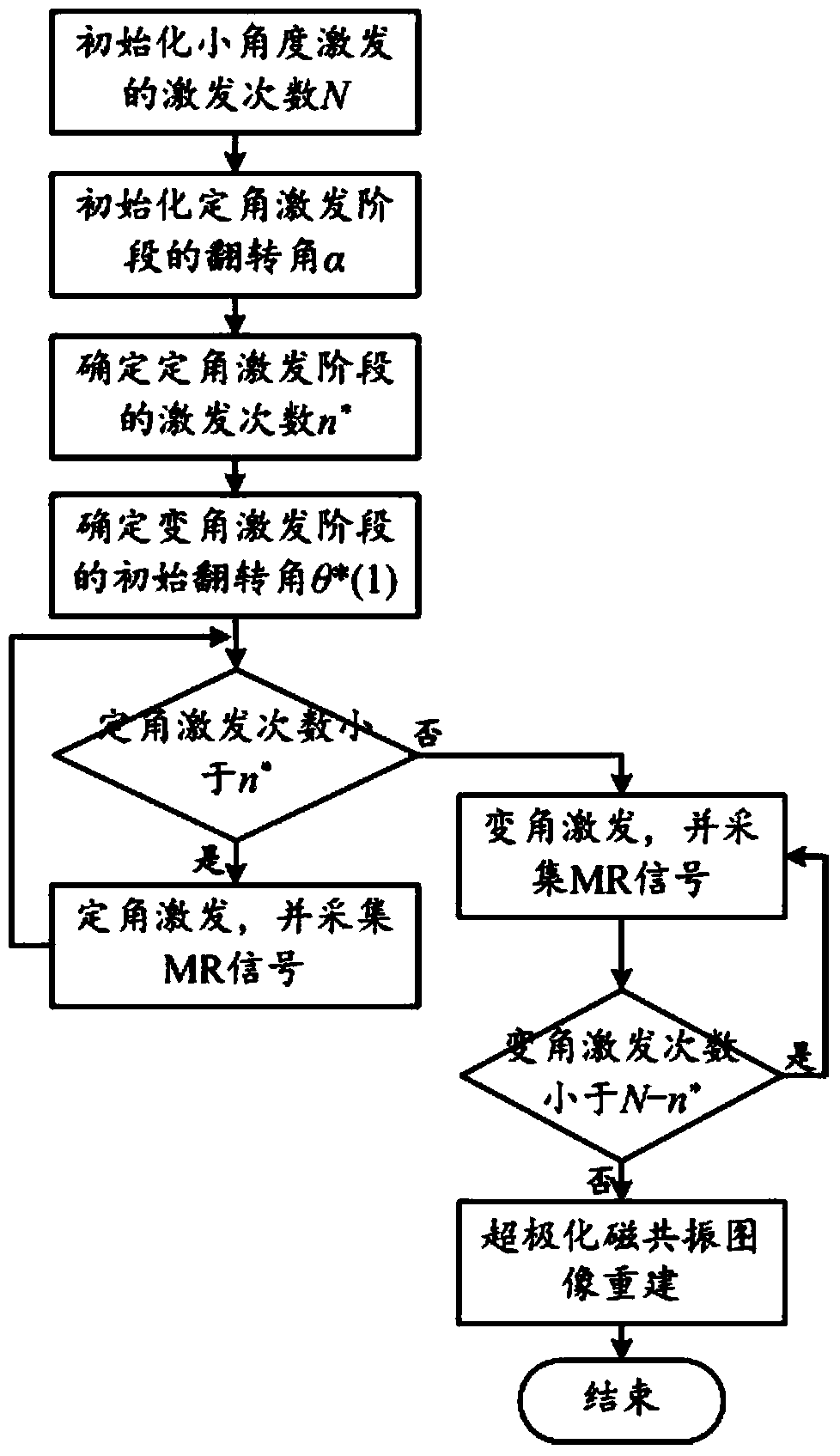

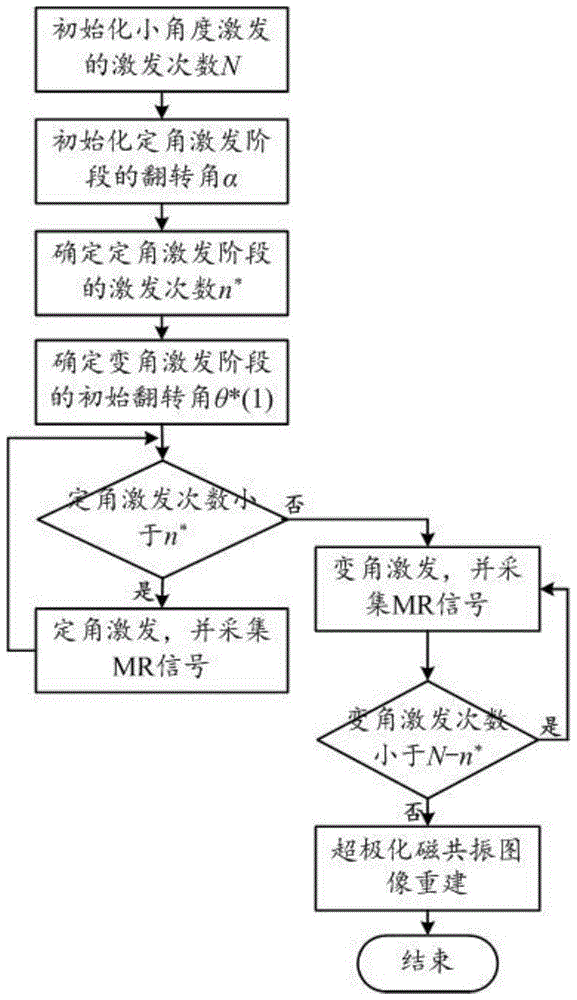

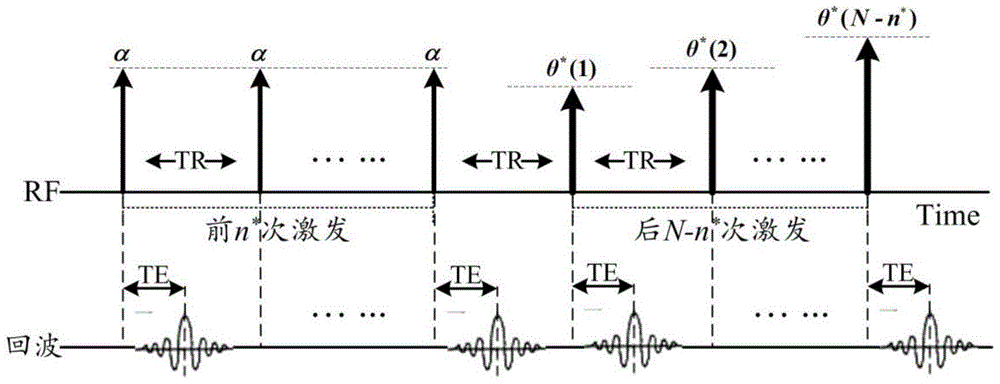

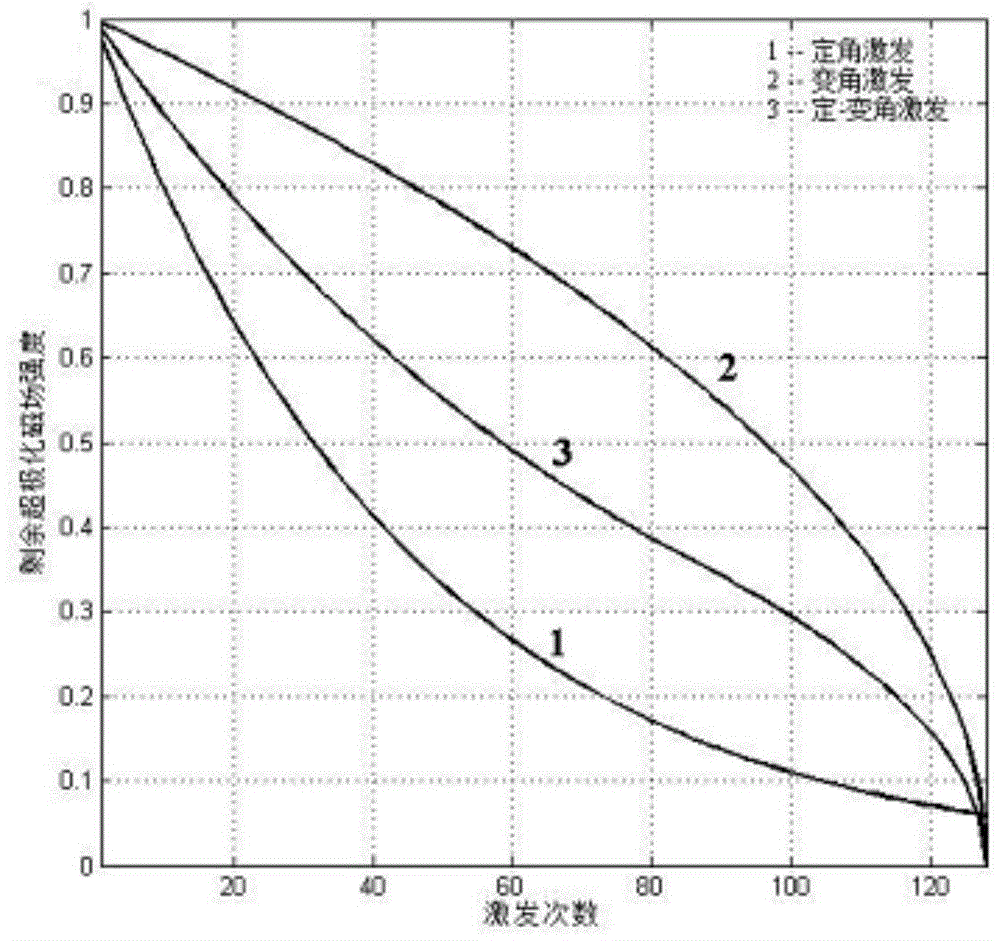

Hyperpolarized magnetic resonance imaging method based on constant angle and variable angle optimization excitation

ActiveCN104181483AImprove signal-to-noise ratioQuality improvementMeasurements using NMR imaging systemsImaging qualityConstant angle

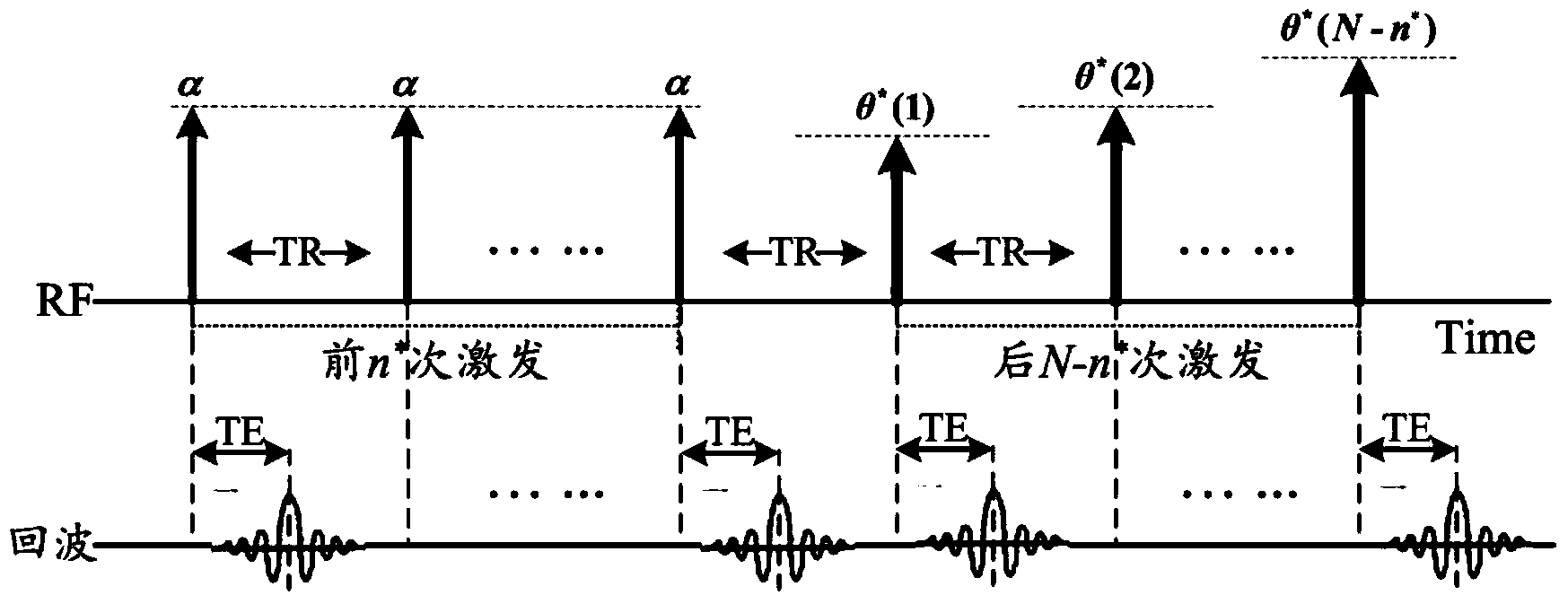

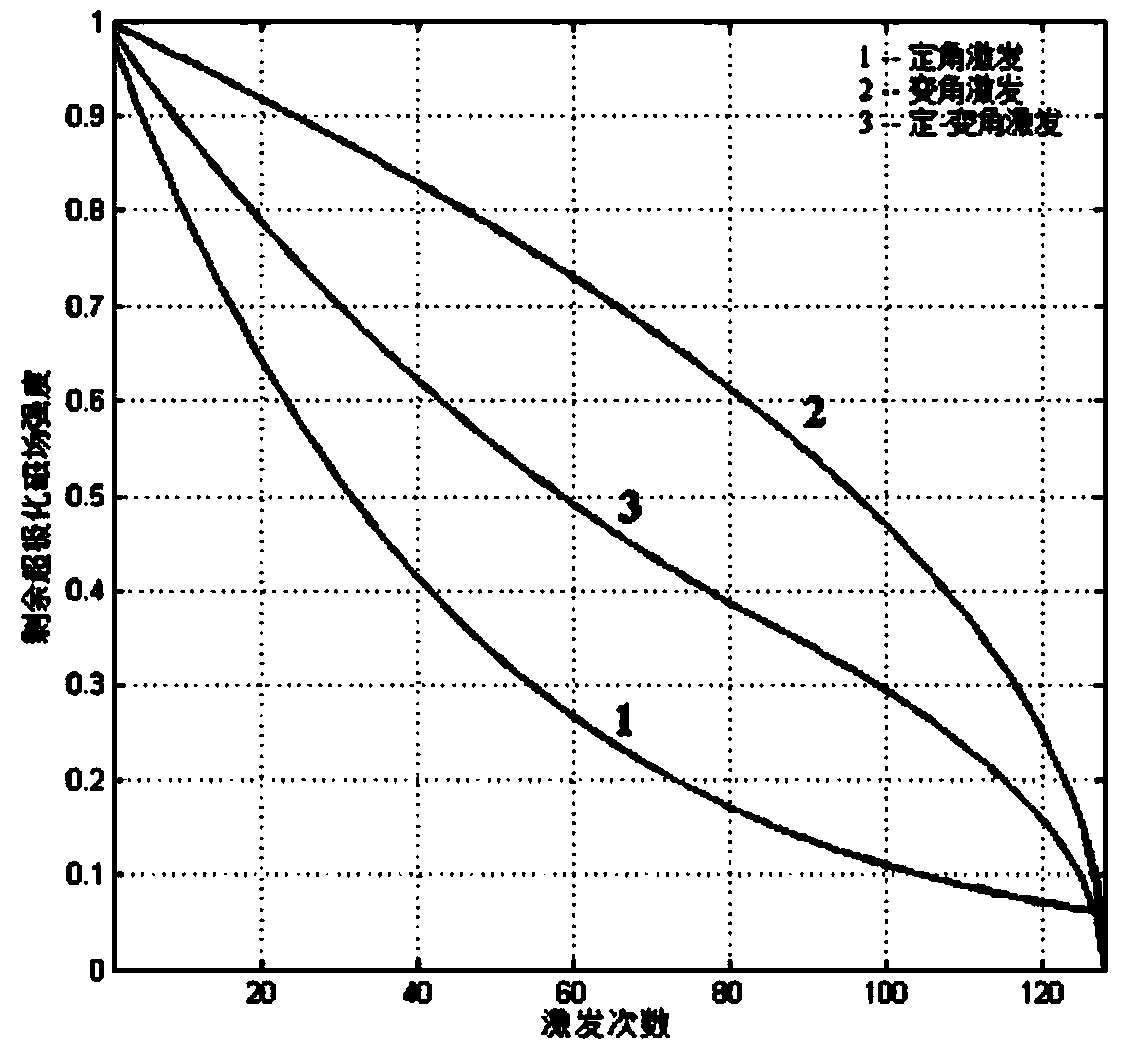

The invention discloses a hyperpolarized magnetic resonance imaging method based on constant angle and variable angle optimization excitation, and relates to the field of magnetic resonance imaging. Advantages of constant angle excitation and advantages of variable angle excitation are synthesized in the method, excitation operation is divided into a constant angle excitation phase and a variable angle excitation phase, in another word, a constant angle excitation method is adopted for previous n* times of excitation, a variable angle excitation method is adopted for consequent N-n* times of excitation, and N is the total number of times of excitation; meanwhile, appropriate constant angle excitation parameters and appropriate variable angle excitation parameters are chosen so that reconstructed MR images can have higher SNRs and better image quality, robustness of algorithms is high, and noise, artifact and the like are obviously reduced compared with those in the prior art.

Owner:武汉中科极化医疗科技有限公司

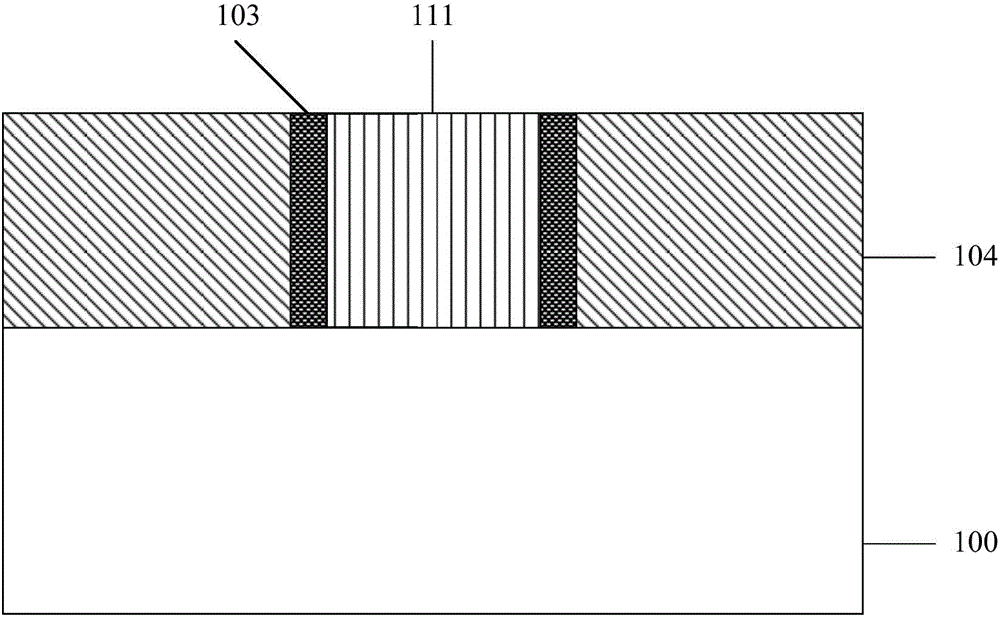

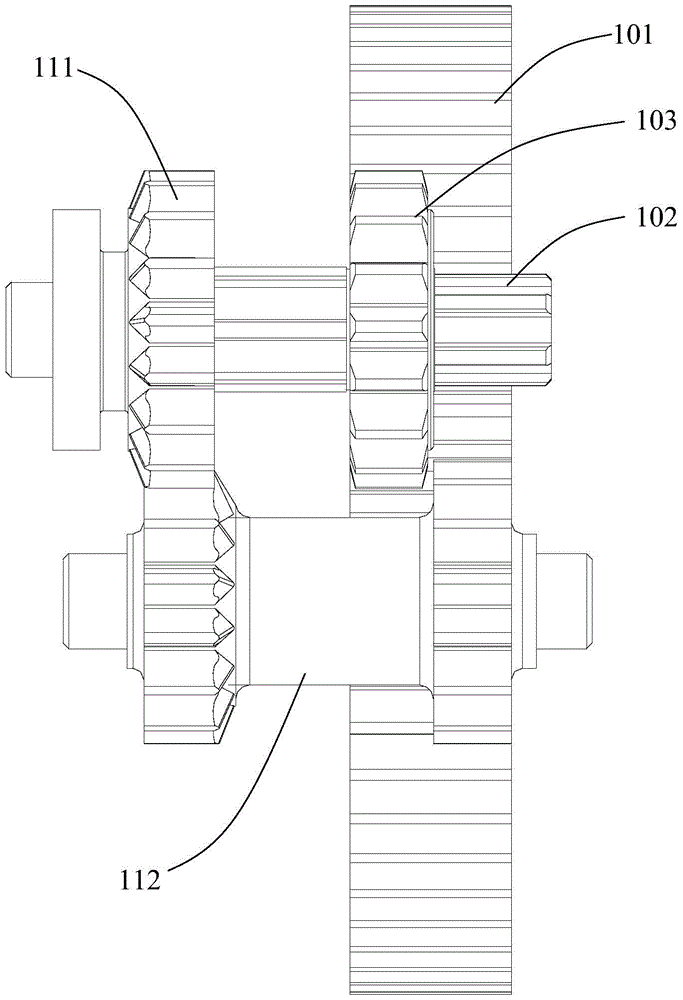

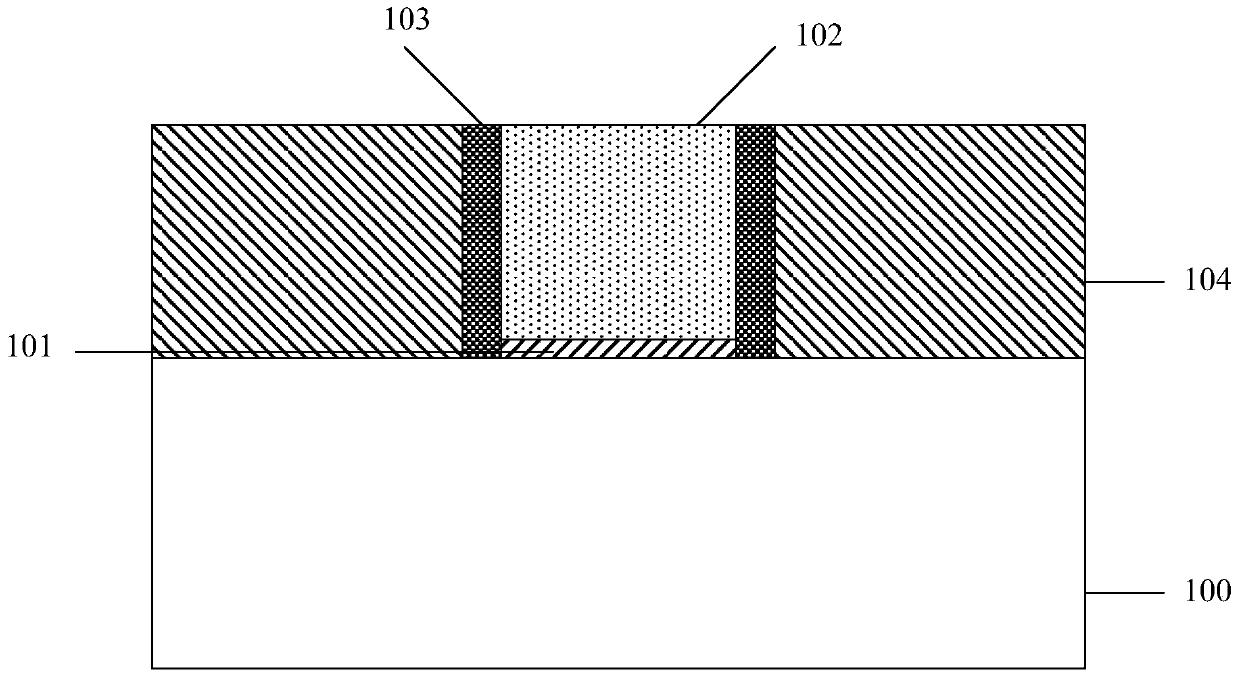

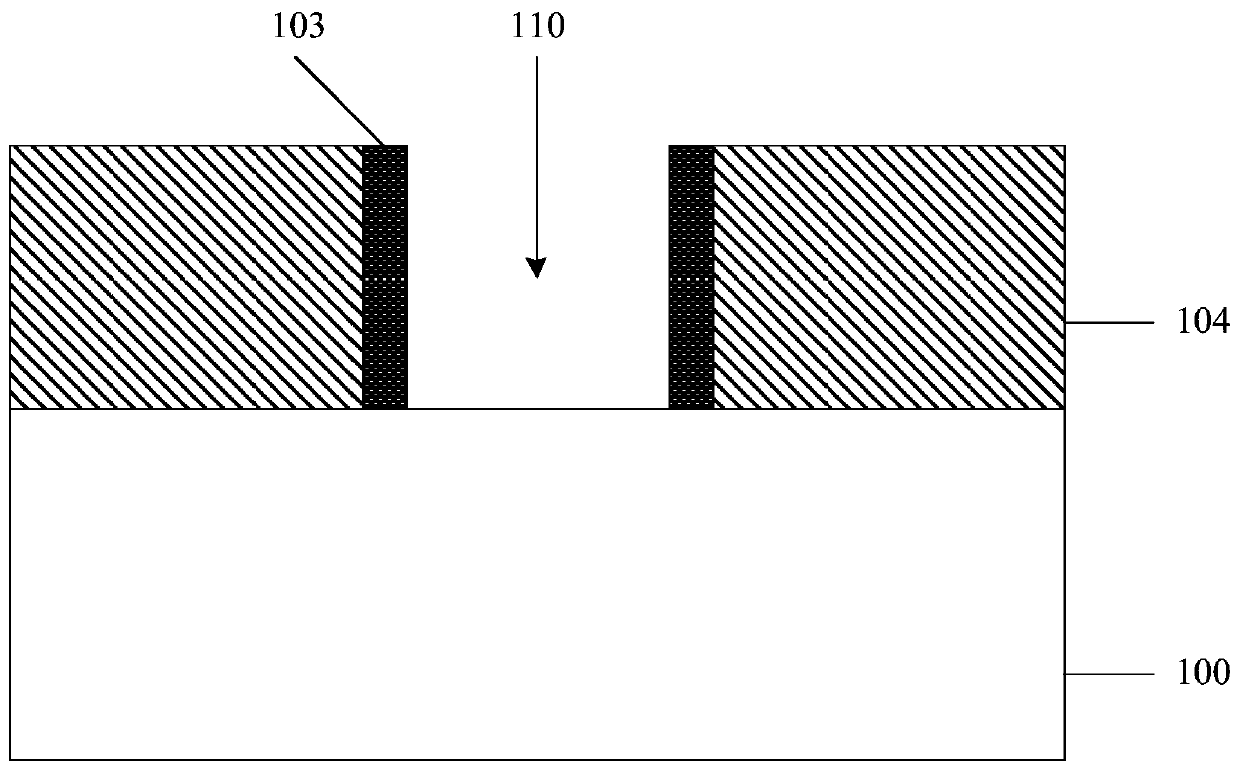

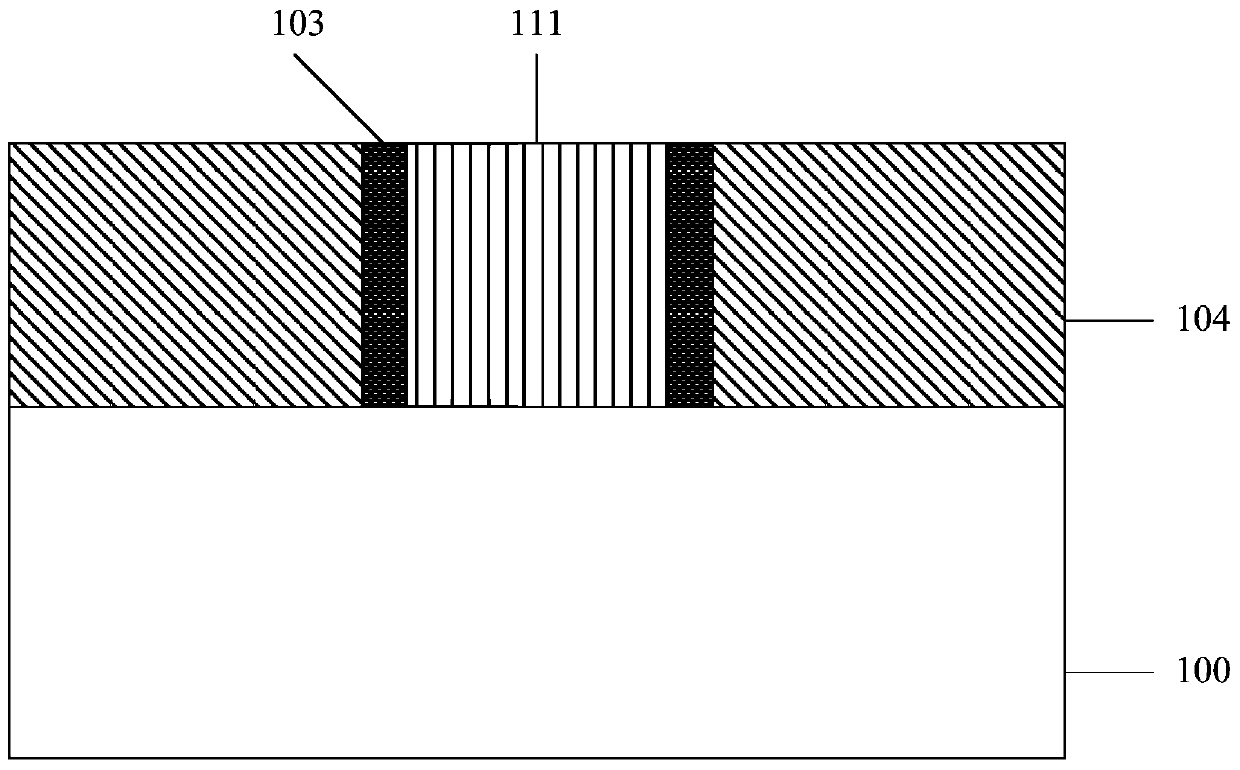

Manufacturing method of transistor

ActiveCN105590861AReduce thicknessAvoid excessive lossesSemiconductor/solid-state device manufacturingMetal gridEtching

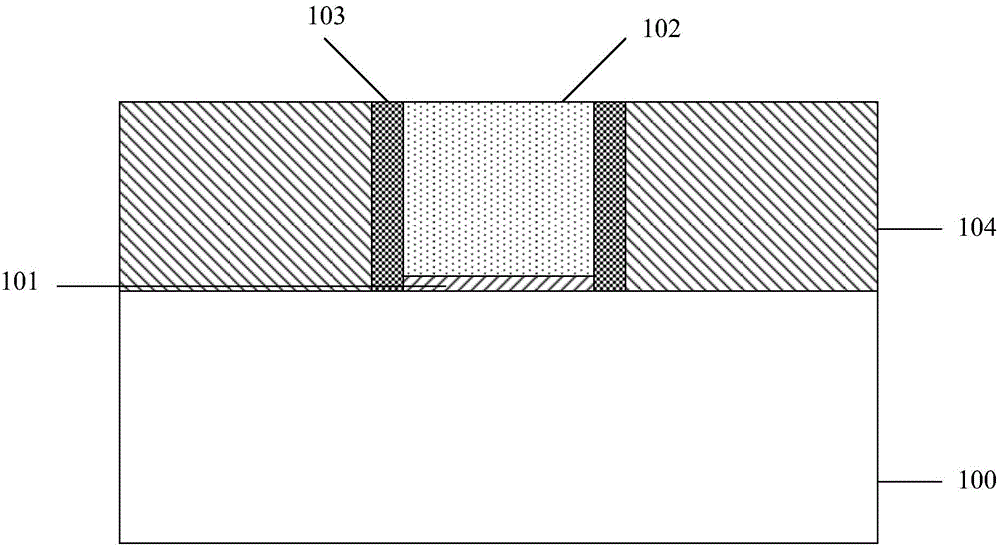

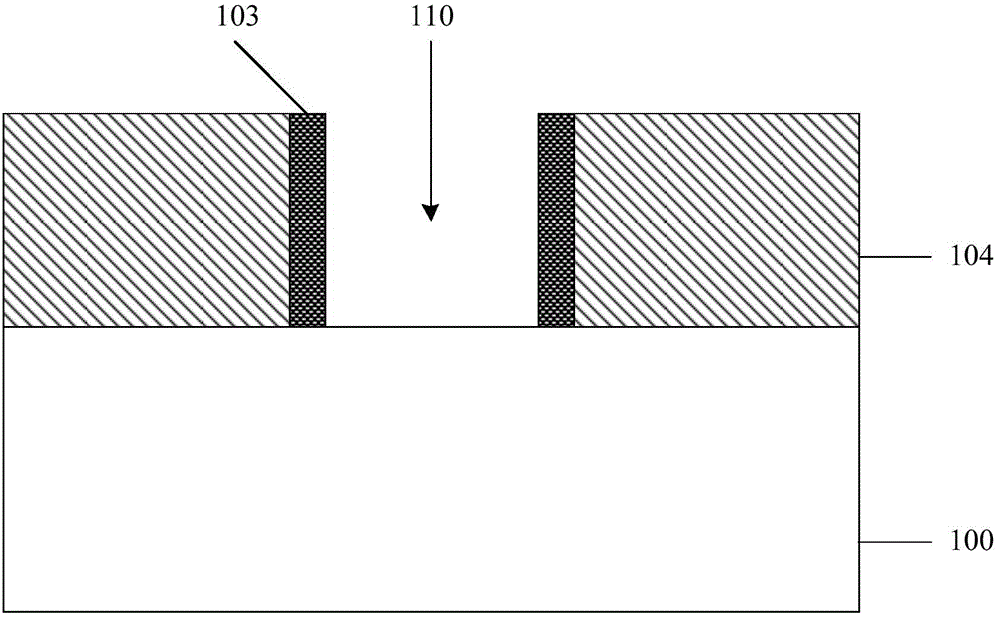

The invention discloses a manufacturing method of a transistor. The method comprises the following steps: providing a semiconductor substrate; successively forming a protective layer, an etching barrier layer and a pseudo grid material layer on the semiconductor substrate; performing first etching on the protective layer, the etching barrier layer and the pseudo grid material layer to form pseudo grids, and a residual etching barrier layer and a residual protection layer which are disposed below the pseudo grids; forming an interlayer dielectric layer on the semiconductor substrate between the pseudo grids; removing the pseudo grids to form a groove exposing the residual etching barrier layer; removing the residual etching barrier layer and the residual protection layer which are disposed in the groove to expose the substrate; and filling the groove exposing the substrate with a grid dielectric layer and a metal material to form a metal grid electrode. According to the invention, through additionally arranging the etching barrier layer on the protective layer, etching with the pseudo grids removed is enabled to well stop at the etching barrier layer, such that the requirements of pseudo grid structure etching and interlayer dielectric layer loss for the thickness of the protective layer are balanced, the performance of the formed transistor is improved, and the yield of the formed transistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

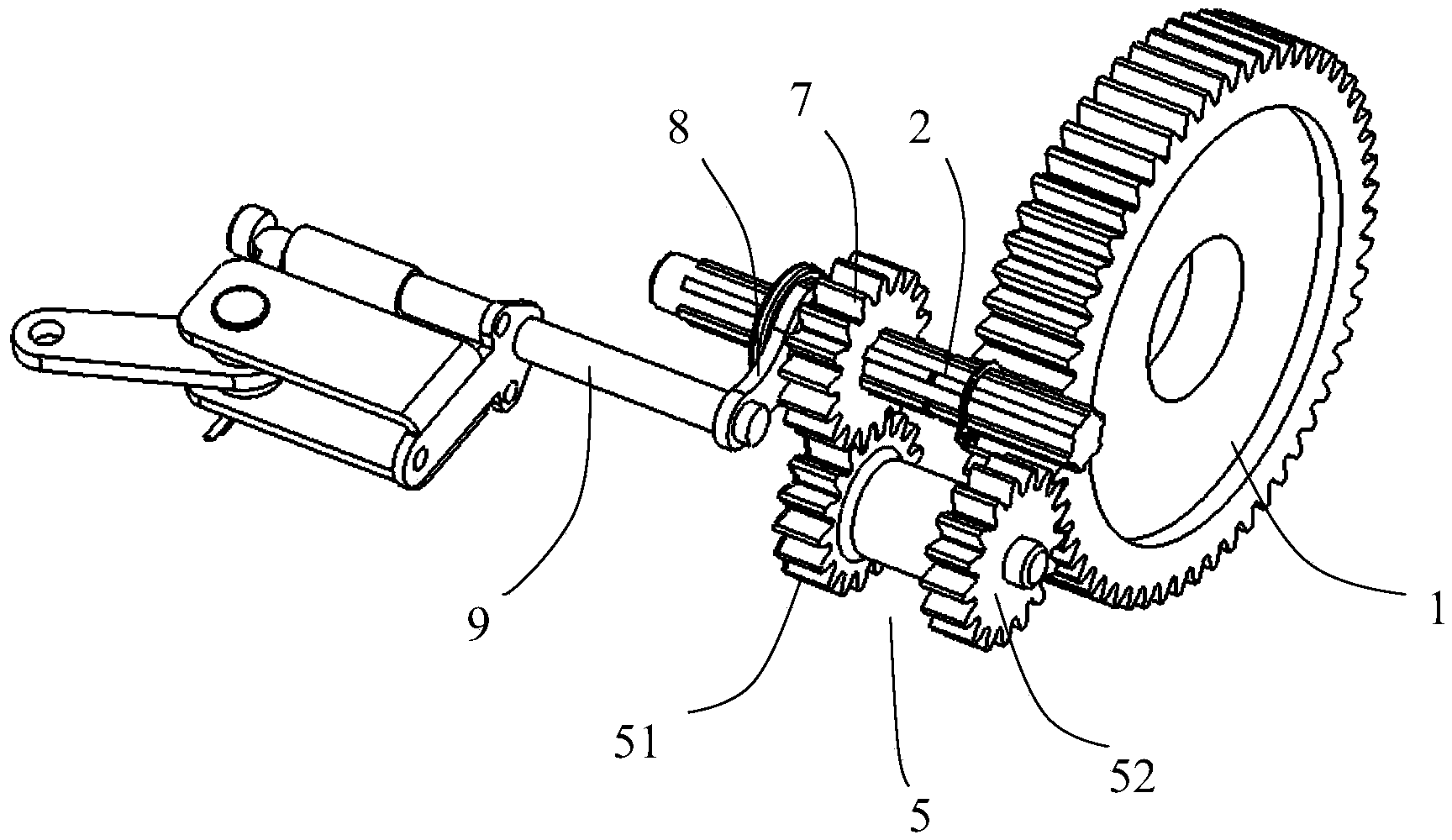

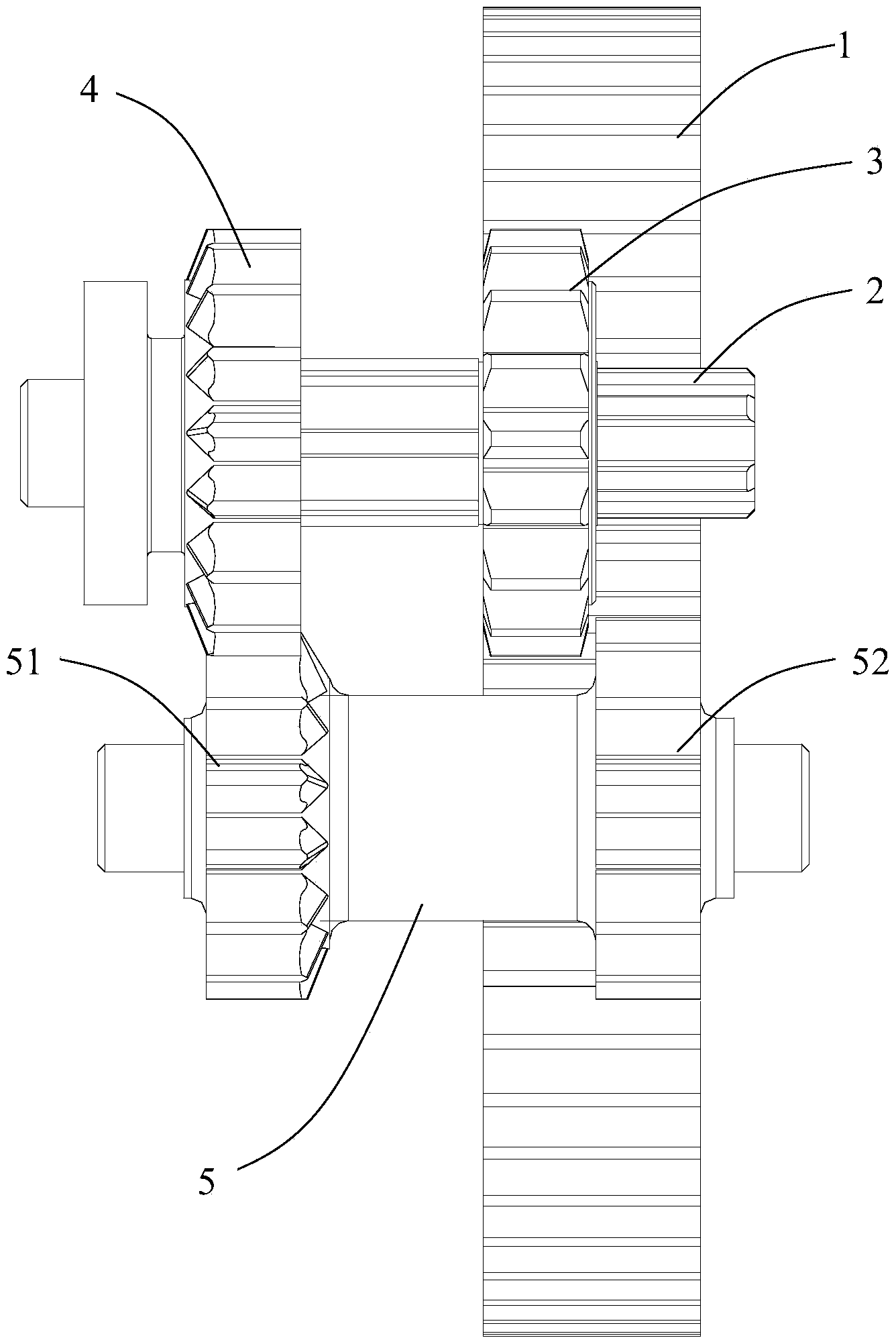

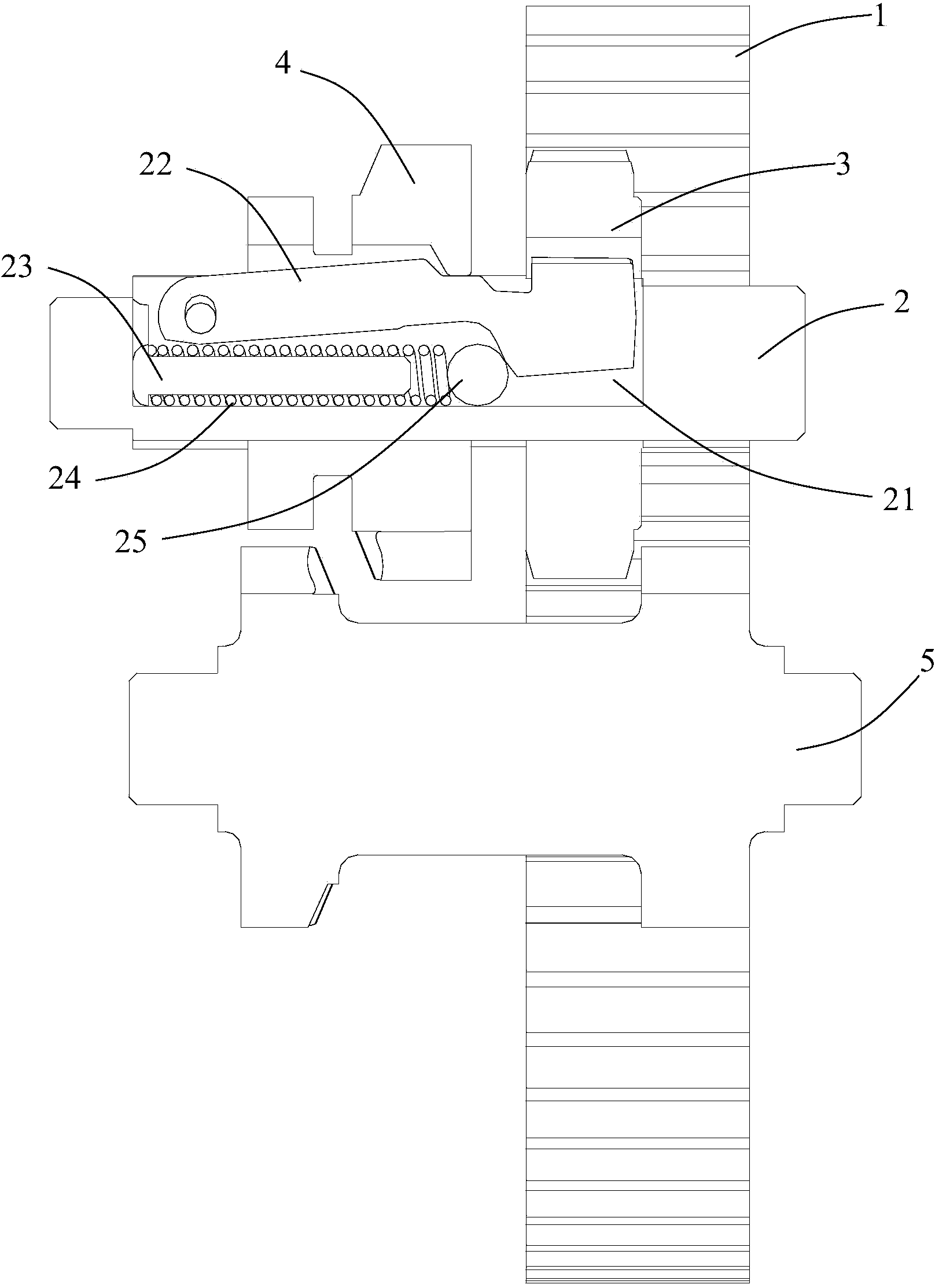

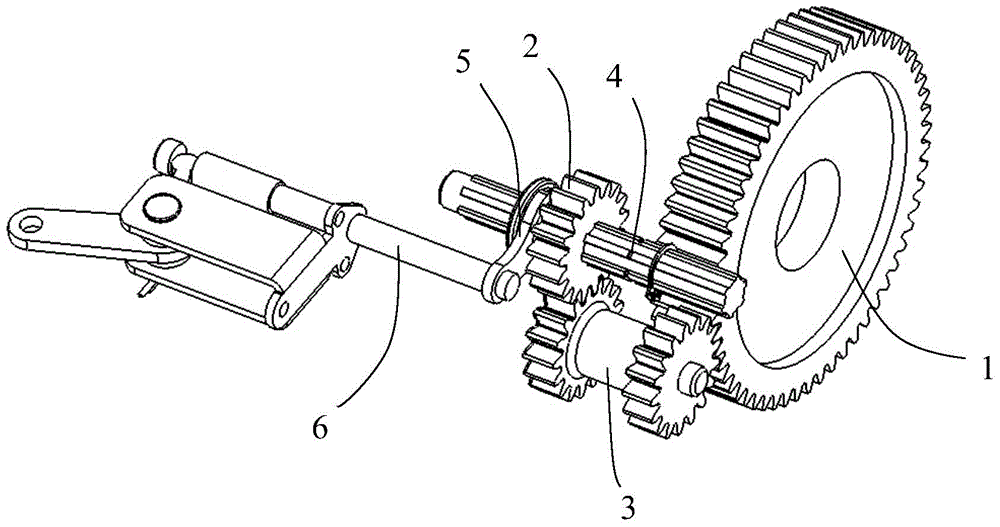

Overdrive transmission device convenient for steering switching

InactiveCN104097505AIncrease success rateImprove fluencyWheel based transmissionSlip couplingDrive shaftEngineering

The invention discloses an overdrive transmission device convenient for steering switching. The transmission device comprises an output gear (1), a driving shaft (2) for providing power for the rotation of the output gear (1), and a turning gear set (5) for realizing reversing rotation of the output gear (1); a forward gear (3) sleeves one end, close to the output gear (1), of the driving shaft (2); the forward gear (3) is engaged with the output gear (1); the driving shaft (2) can be locked with the forward gear (3) so that the output gear (1) can be driven to rotate forward by use of the forward gear (3). The overdrive transmission device convenient for steering switching is capable of smoothly realizing steering switching of the output gear and effectively saving energy source.

Owner:CHONGQING HIJOY IND GRP

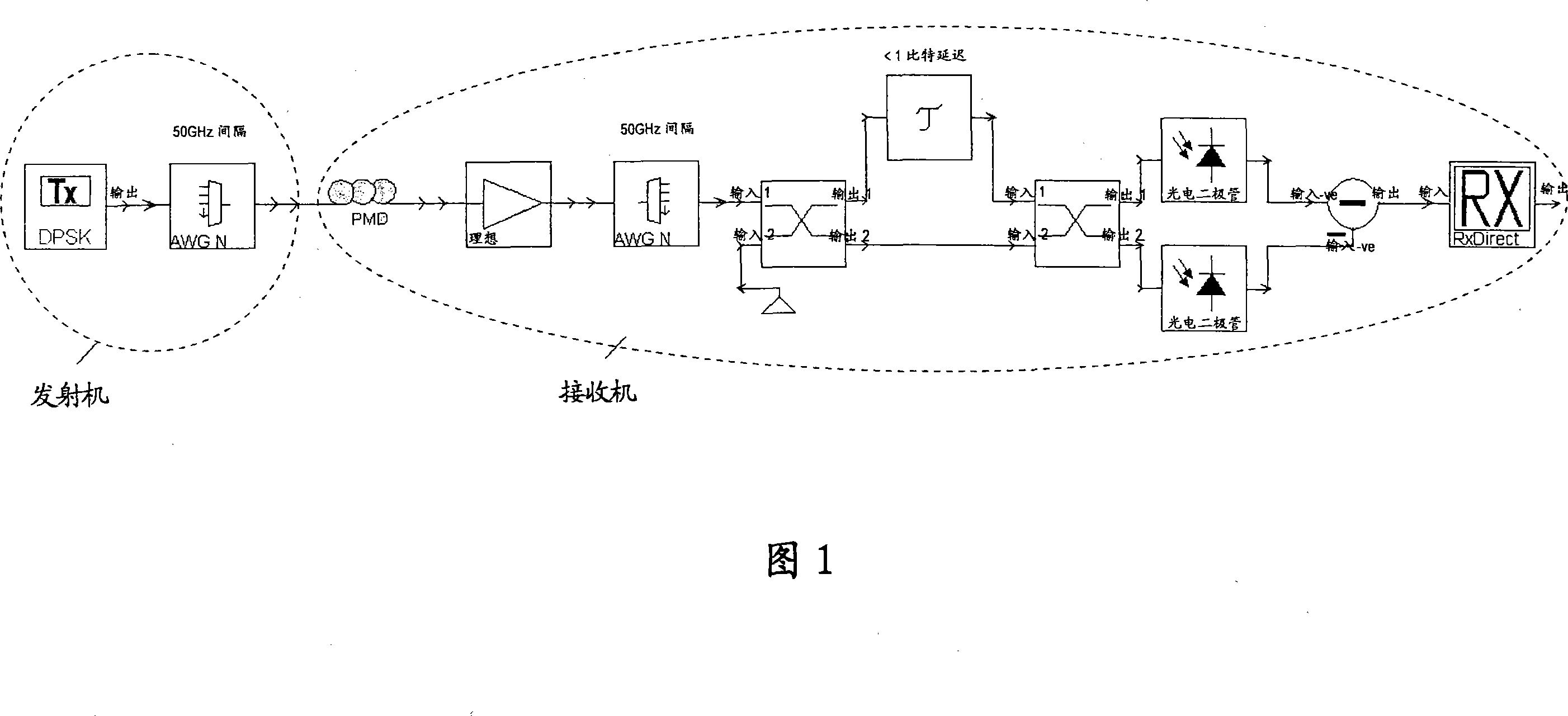

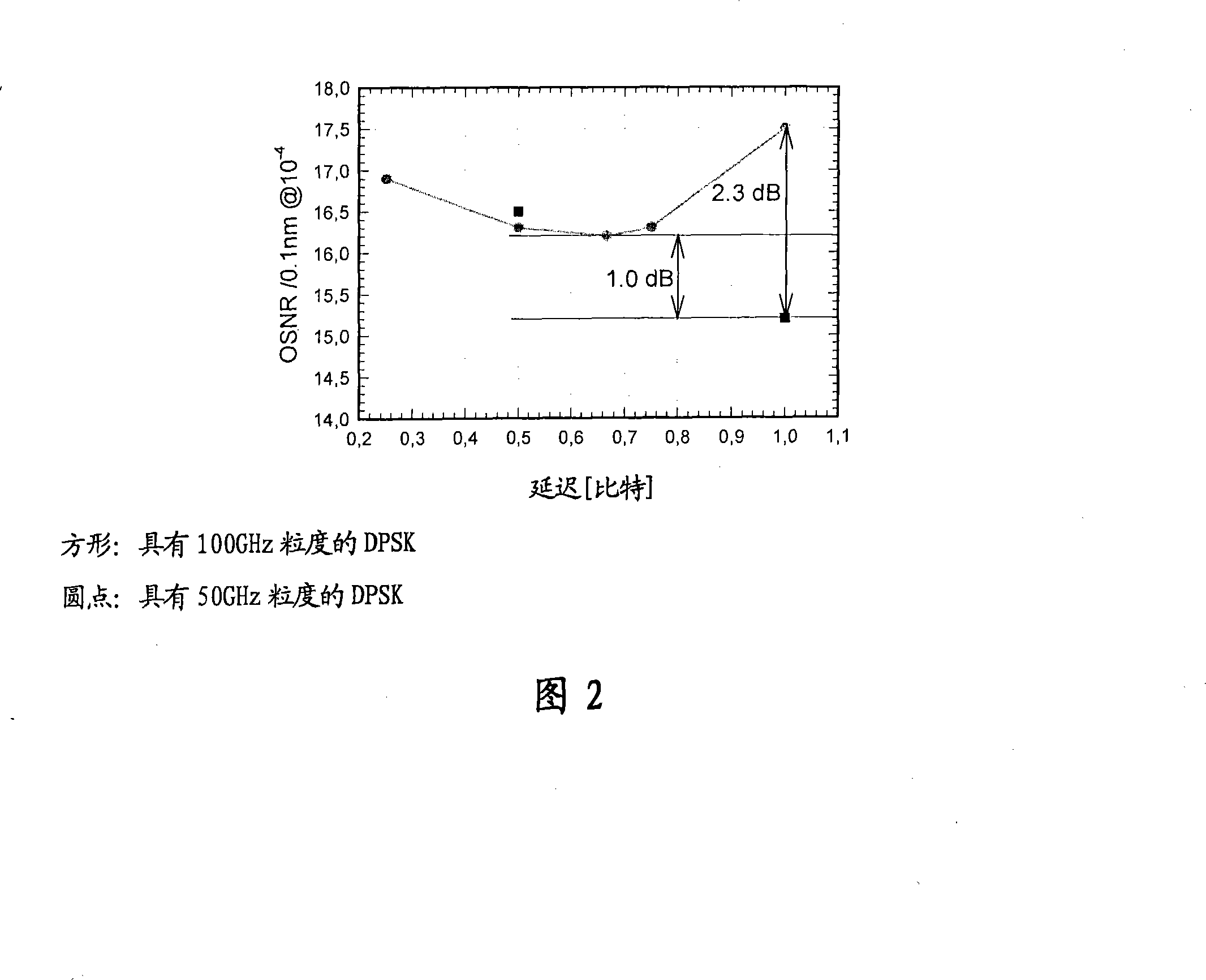

Method and receiver to increase the spectral efficiency of dpsk modulation format

InactiveCN101162948AAvoid excessive lossesWavelength-division multiplex systemsPhase-modulated carrier systemsPhase conversionFrequency spectrum

The optical DPSK demodulator converts phase into amplitude variations by delaying one path of an interferometer by one bit period. This operation includes a differentiation of the transmitted signal, which must be counteracted by applying a precoder at the TX side. By variation of the delay within the interferometer the differentiation will be changed. A reduction of the delay results in an emphasis of higher frequencies. This can be used to counteract the low pass behaviour (after detection) produced by narrowband optical filters. A penalty reduction from >2 dB to ~1 dB is expected.

Owner:ALCATEL LUCENT SAS

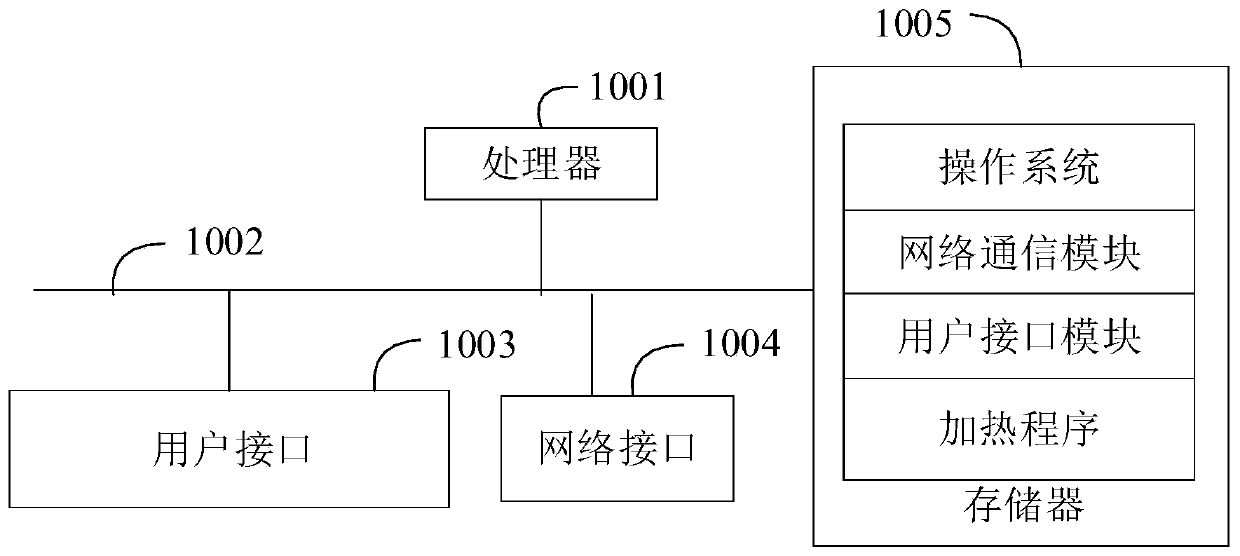

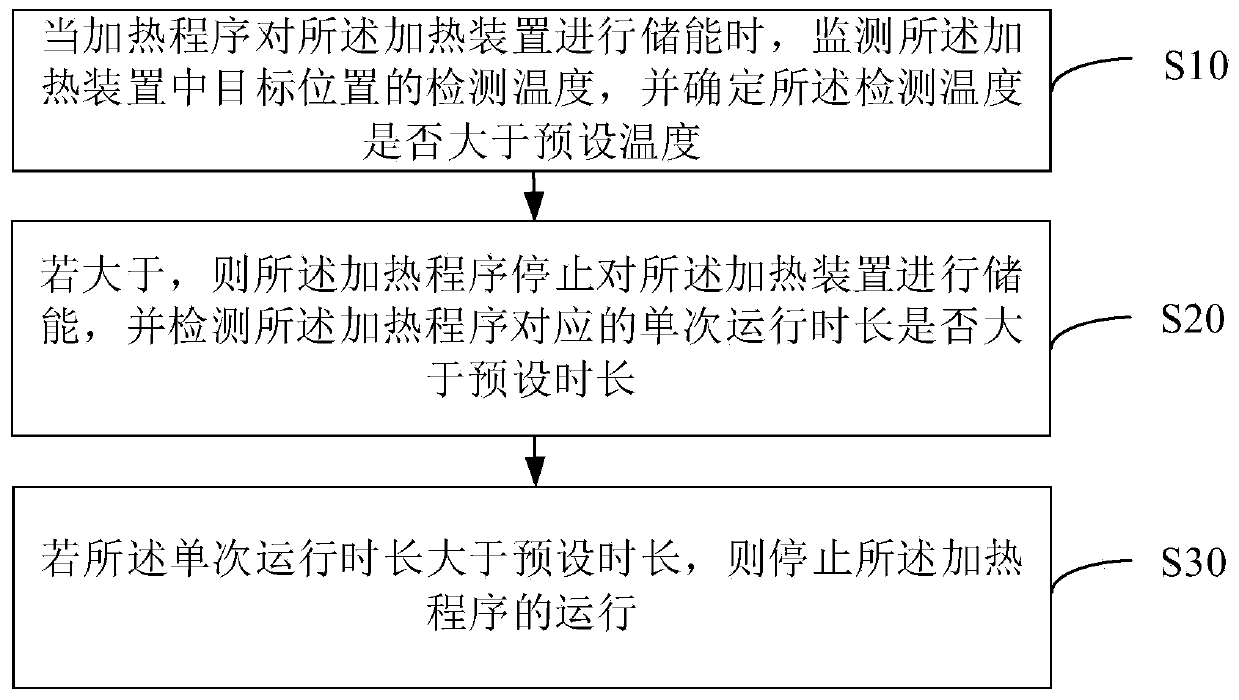

Heating device and method, heating control system and computer readable storage medium

The invention discloses a heating device and method, a heating control system and a computer readable storage medium. The heating method comprises the steps: monitoring the detection temperature of atarget position in a heating device when a heating program carries out energy storage of the heating device, and determining whether the detection temperature is greater than a preset temperature or not; if so, stopping energy storage of the heating device by the heating program, and detecting whether the single operation duration corresponding to the heating program is larger than the preset duration or not; and if so, stopping the operation of the heating program. Therefore, a technical problem that when the existing heater conducts heating, the heat loss is large is solved.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA +1

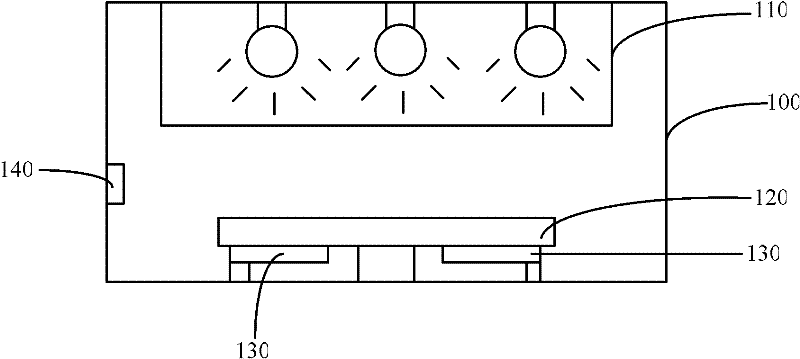

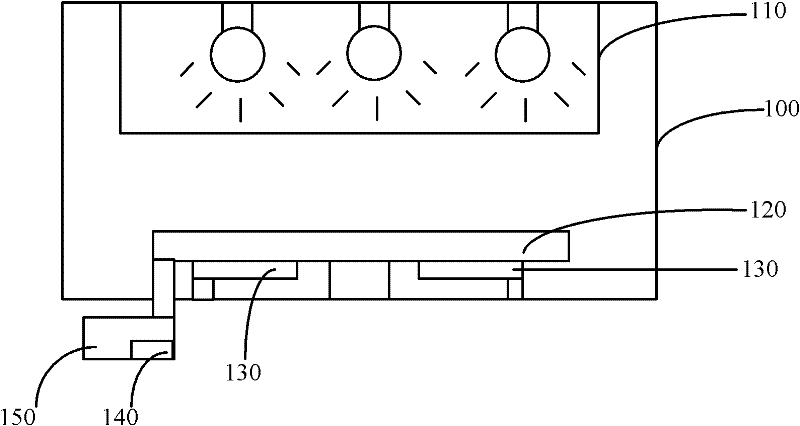

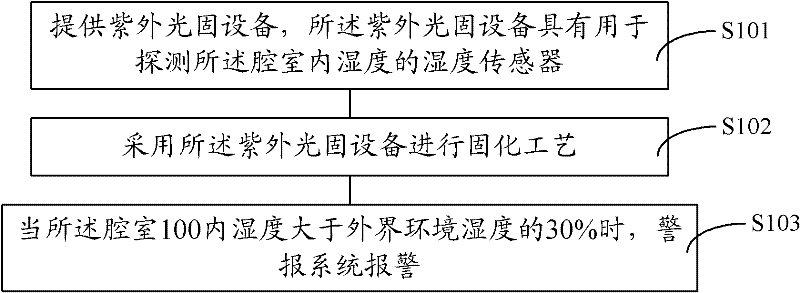

Ultraviolet light curing device and alarm method thereof

ActiveCN102231047AAvoid excessive lossesAvoid production lossPhotomechanical exposure apparatusAlarmsTroubleshootingMoisture sensor

The invention provides an ultraviolet light curing device and an alarm method thereof, wherein the ultraviolet light curing device comprises a chamber, an ultraviolet light generating device, a substrate bearing disc, a water cooling device and a humidity sensor, wherein the ultraviolet light generating device is arranged in the chamber; the substrate bearing disc is arranged opposite to the ultraviolet light generating device; the water cooling device is arranged at the bottom of the substrate bearing disc; the humidity sensor is used for detecting the humidity in the chamber, and the humidity sensor gives out an alarm when the humidity in the chamber is greater than a set value. The ultraviolet light curing device and the alarm method thereof provided by the invention can be used for avoiding the production losses in a light curing process in batches and further has the advantages of high alarm accuracy, large alarm range and timely trouble shooting.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

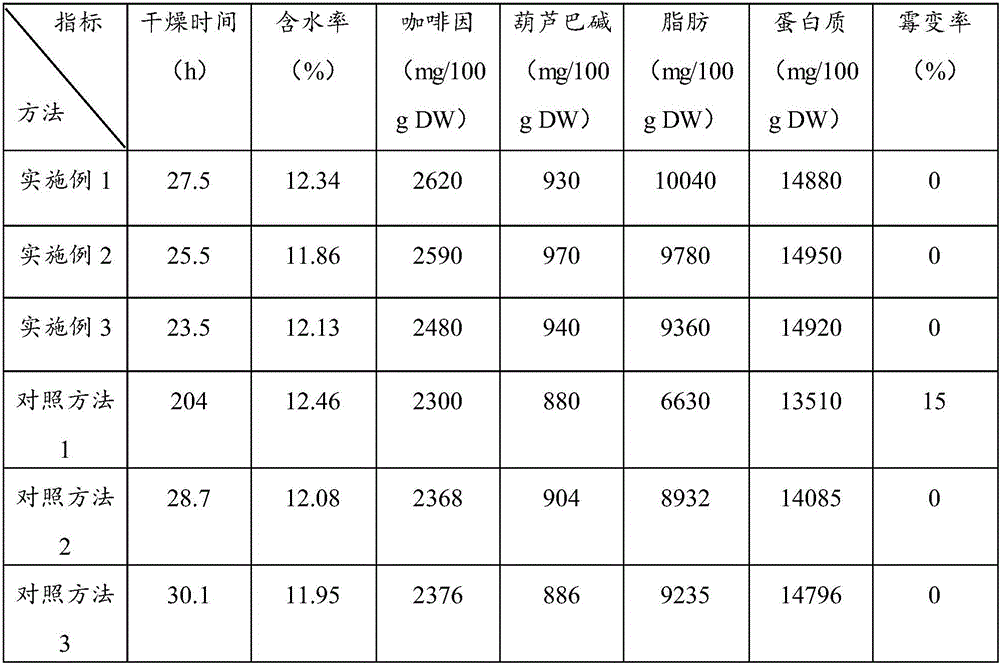

Vacuum freeze-dried green coffee beans and processing method thereof

ActiveCN105815516ARetain flavor componentsRetain nutrientsGreen coffee treatmentThree stageFreeze-drying

The invention relates to the field of food preliminary processing and discloses vacuum freeze-dried green coffee beans and a processing method thereof.According to the processing method, fresh coffee fruits are cleaned and drained before being pre-frozen; the fresh coffee fruits are subjected to vacuum freeze-drying at three stages; at the first stage, 30 min is spent, the temperature is raised by gradient to 50-60 DEG C, and constant-temperature drying is carried out for 12.5-14.5 h; at the second stage, 15 min is spent, the temperature is dropped by gradient to 45-55 DEG C, and constant-temperature drying is carried out for 7-9 h; at the third stage, 15 min is spent, the temperature is dropped by gradient to 40-50 DEG C, and constant-temperature drying is carried out for 2-4 h; lastly, the fresh coffee fruits are subjected to shelling and vacuum packaging, and the vacuum freeze-dried green coffee beans are obtained.A peculiar three-stage vacuum freeze-drying process is adopted for preliminary processing of the fresh coffee fruits, the green coffee beans with a good condition and many nutritional substances and flavored active substances are obtained; meanwhile, processing time is shortened in the whole process, and processing efficiency of the coffee preliminary processing industry is improved.

Owner:SPICE & BEVERAGE RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Method for prolonging shelf life of rice

InactiveCN107865079AReduce moisture contentExtended storage timeSeed preservation by coatingFood processingImpurityWater content

The invention discloses a method for prolonging shelf life of rice. The method is characterized by comprising the following steps of (1) performing drying in sunshine: naturally drying harvested rice,and removing impurities of weeds, pebbles and the like in the rice with a blowing sieving machine; (2) performing baking: transferring the dried rice in a convey-type baking machine for baking, and performing baking for 2-3 times until the water content of the rice is 9-11%; (3) performing protecting: spreading the baked rice, performing spraying with protecting liquid, and placing the rice underthe low temperature environment for 2-3 days; and (4) performing storage: putting the protected rice in a sealed warehouse for storage and preservation, leading ozone in the sealed warehouse once every half a month, and lowering the temperature of the warehouse once each month.

Owner:蚌埠市禹会区马城胡本号家庭农场

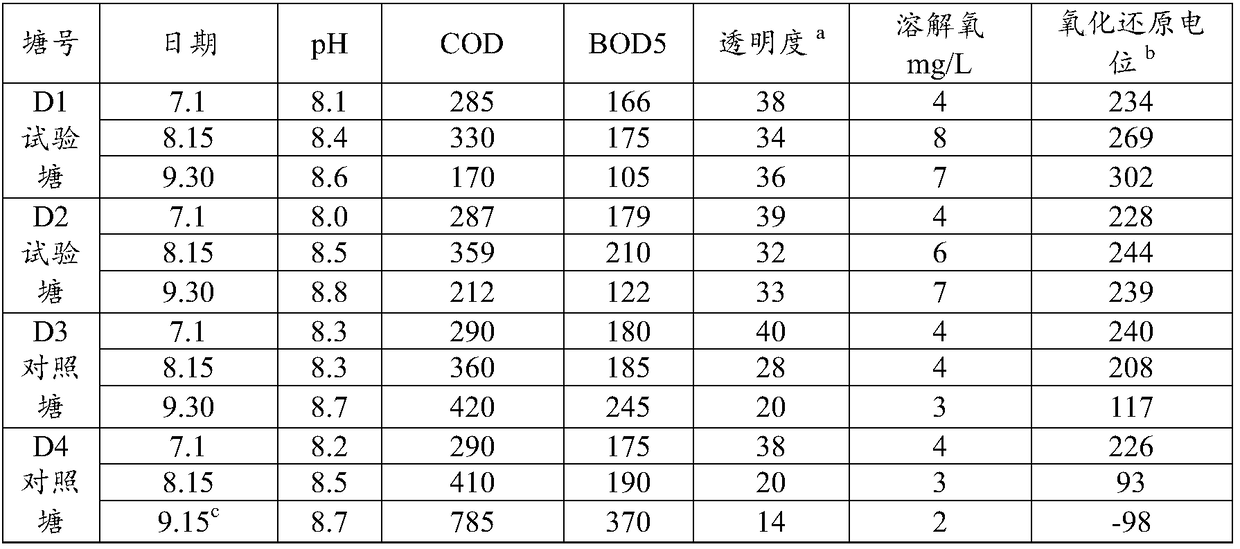

Microbial preparation for ecological safety water systems and preparation method thereof

Relating to the technical field of water treatment, the invention provides a microbial preparation for ecological safety water systems and a preparation method thereof. The microbial preparation comprises: a composite strain composed of 10-20% of rhodopseudomonas palustris, 20-30% of pichia farinose, 20-30% of bacillus amyloliquefaciens, 0-15% of rhodococcus erythropolis, 20-30% of lactobacillus plantarum, and 5-15% of ectothiorhodospira shaposhnikovii; and a carrier for loading the composite strain. The preparation method includes: adding the composite strain into a culture solution, and conducting fermentation culture to obtain a fermentation broth; concentrating the fermentation broth, adding porous starch, conducting stirring adsorption, then adding dextrin and lithium tourmaline micropowder, laying an activated carbon fiber cloth therein to undergo adsorption for 2-3h, and then performing drying. In the microbial preparation, all bacterial strains play a synergistic role to effectively restore the water so as to form a beneficial micro-ecological environment, and the bacterial strains are immobilized on the carrier to effectively improve the microbial purification and restoration effect.

Owner:普乐格(厦门)生物科技有限公司

Preparation method of cellulose acetate particles

The invention discloses a preparation method of cellulose acetate particles. The preparation method comprises the following steps: firstly, soaking cellulose in an acetic acid solution containing sulfuric acid for activation, then mixing the activated cellulose with a mixed solution containing catalyst hydrosulfate, acetic acid and acetic anhydride, reacting to obtain a cellulose triacetate solution, then adding an acetic acid aqueous solution for hydrolysis, separating out the reacted cellulose acetate solution in an acetic acid aqueous solution, and carrying out suction filtration, washing and freeze drying to obtain powdery coarse cellulose acetate particles; and dissolving the crude product in an acetone solution, purifying, re-precipitating, carrying out suction filtration, washing, and drying to obtain high-purity cellulose acetate particles. According to the method, the raw material with low cellulose content can be acetylated, the viscosity and molecular weight of the cellulose acetate are not obviously reduced, the cooling acetylation reaction is not required, the solubility of the cellulose acetate is improved, and the influence of the catalyst or the catalyst residue on acetylation, hydrolysis and subsequent processing steps is very small.

Owner:天津信诚康达药业有限公司

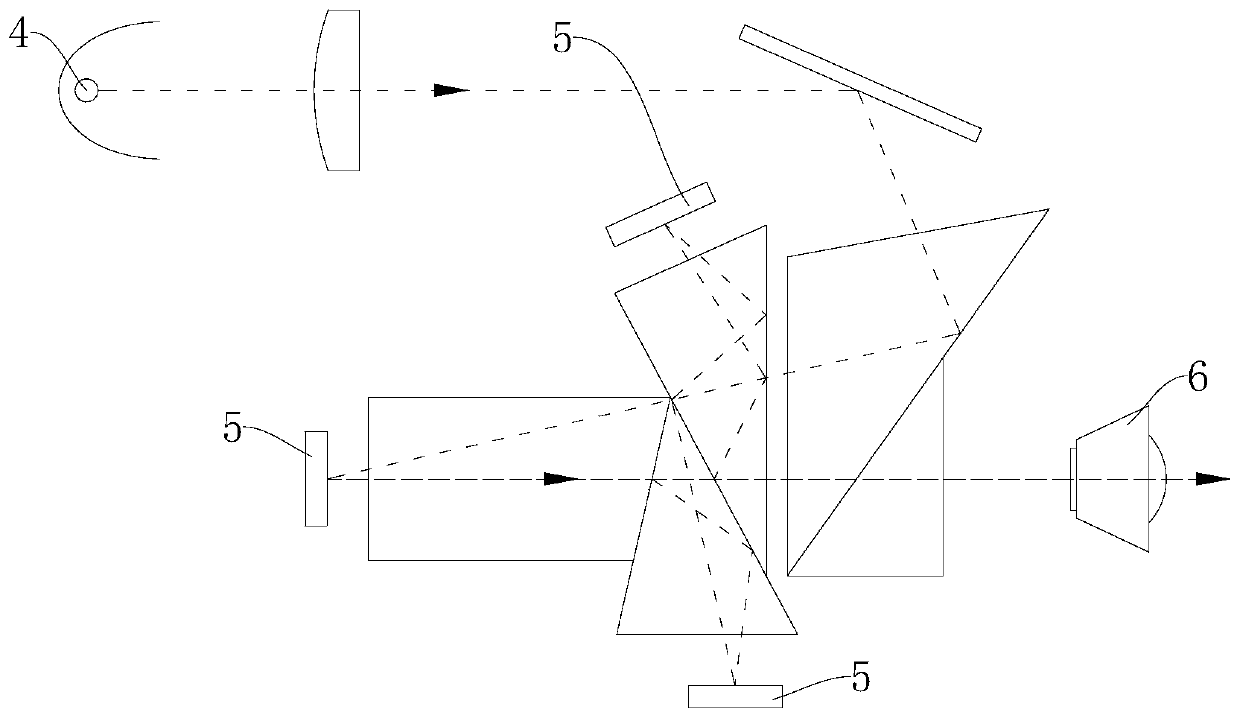

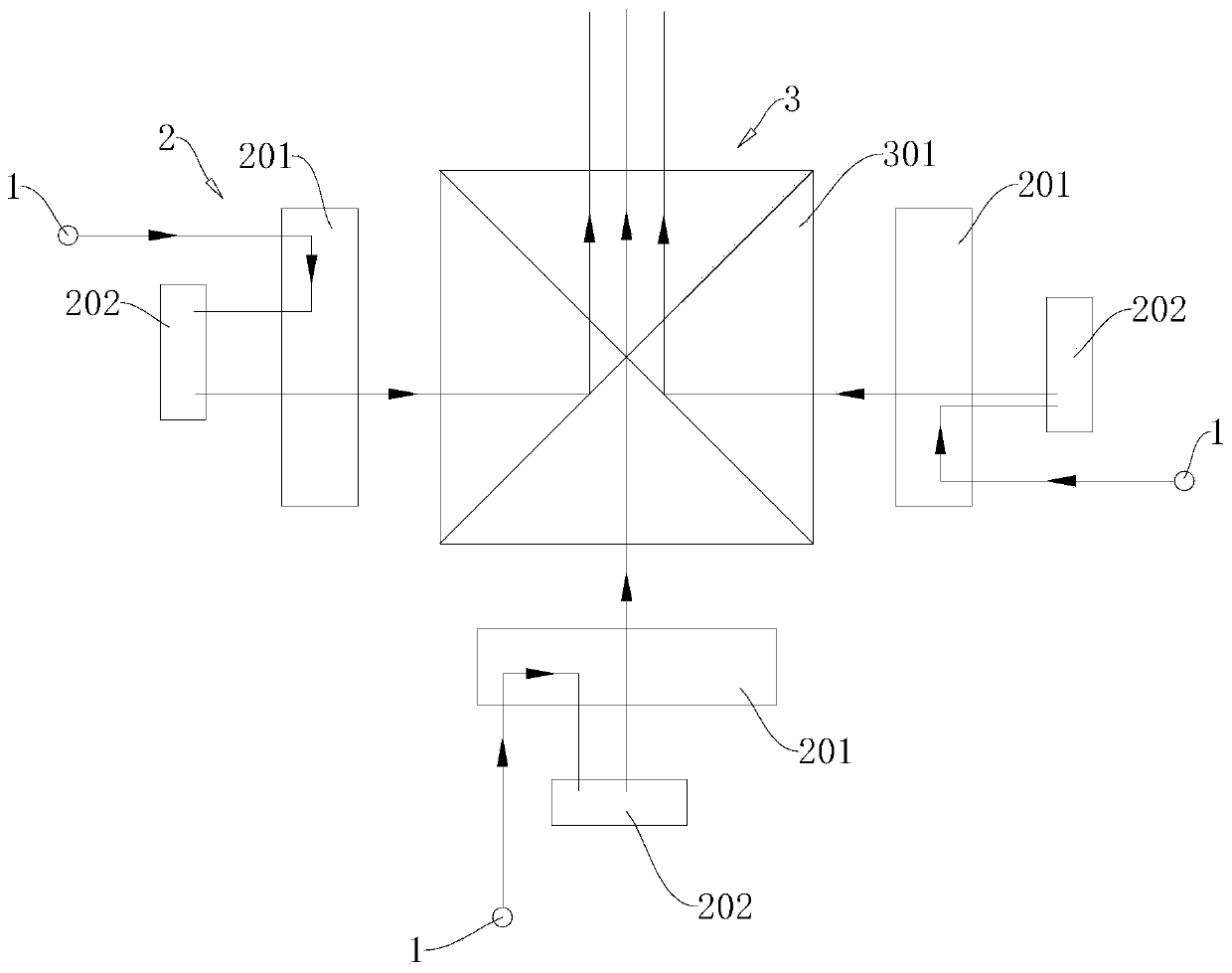

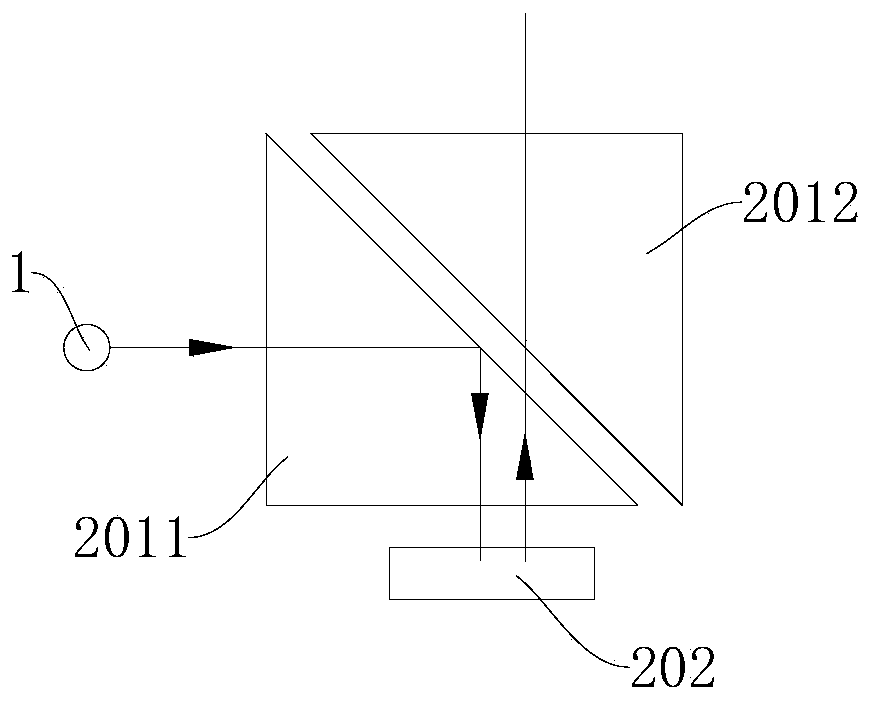

Light path system and projector

The invention provides a light path system and a projector, and belong to the field of projection equipment. The projector comprises monochromatic light sources, light processing assemblies and lightcombining elements. The number of the monochromatic light sources is multiple, and the monochromatic light sources emit light of at least two colors. The multiple light processing assemblies are in one-to-one correspondence with the multiple monochromatic light sources, and the light processing assemblies are used for enabling light rays of the monochromatic light sources to form images; the lightcombining elements are in one-to-one correspondence with the light processing assemblies, and the light combining elements are used for receiving light emitted by the light processing assemblies andcarrying out light mixing processing. According to the light path system and the projector provided by the invention, a complex light path structure of color separation first and then color combination in a traditional light path system is not needed, the number of optical elements is reduced, the structure of the light path system is simplified to a great extent, the situation of excessive lightloss is avoided, meanwhile, a dark field can be set for each path of light, and the contrast ratio is improved.

Owner:SHENZHEN INTELA LASER TECH CO LTD

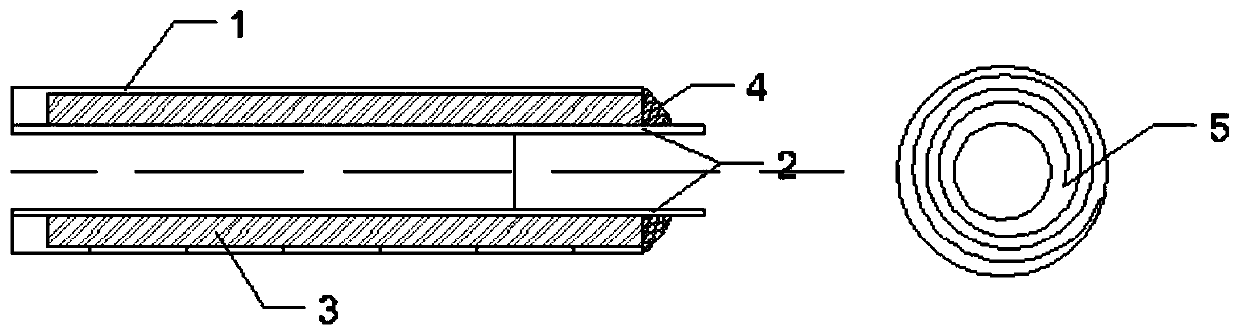

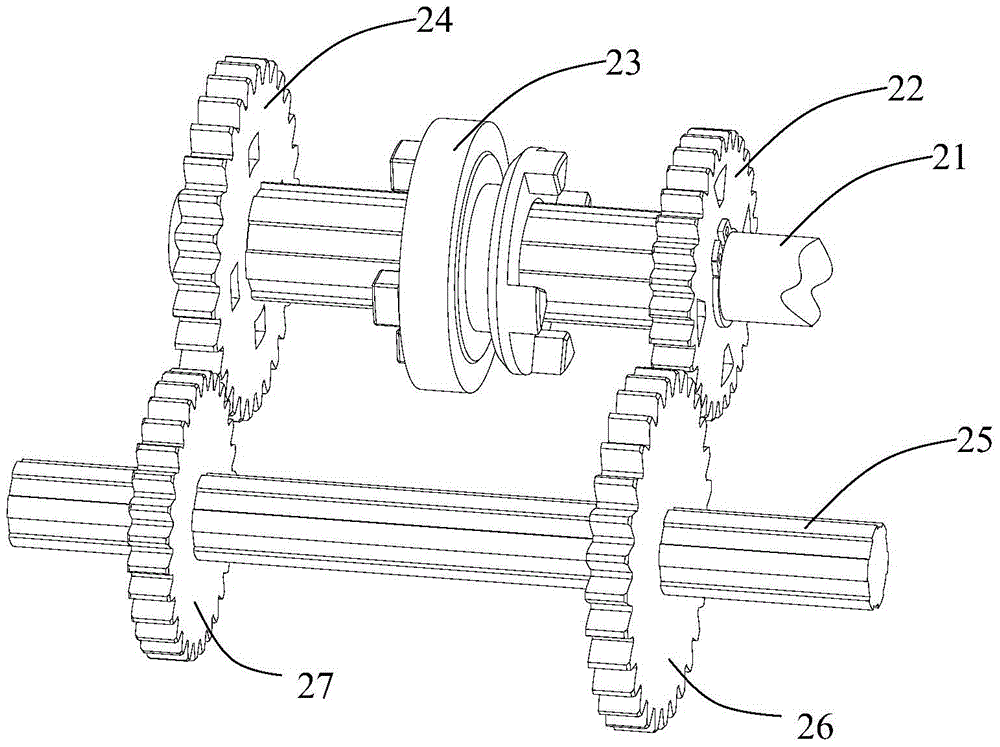

Overrunning transmission device convenient to switch

ActiveCN105059109AIncrease success rateImprove fluencyWheel based transmissionSlip couplingDrive shaftEngineering

The invention discloses an overdrive transmission device convenient for steering switching. The transmission device comprises an output gear (1), a driving shaft (2) for providing power for the rotation of the output gear (1), and a turning gear set (5) for realizing reversing rotation of the output gear (1); a forward gear (3) sleeves one end, close to the output gear (1), of the driving shaft (2); the forward gear (3) is engaged with the output gear (1); the driving shaft (2) can be locked with the forward gear (3) so that the output gear (1) can be driven to rotate forward by use of the forward gear (3). The overdrive transmission device convenient for steering switching is capable of smoothly realizing steering switching of the output gear and effectively saving energy source.

Owner:CHONGQING HIJOY IND GRP

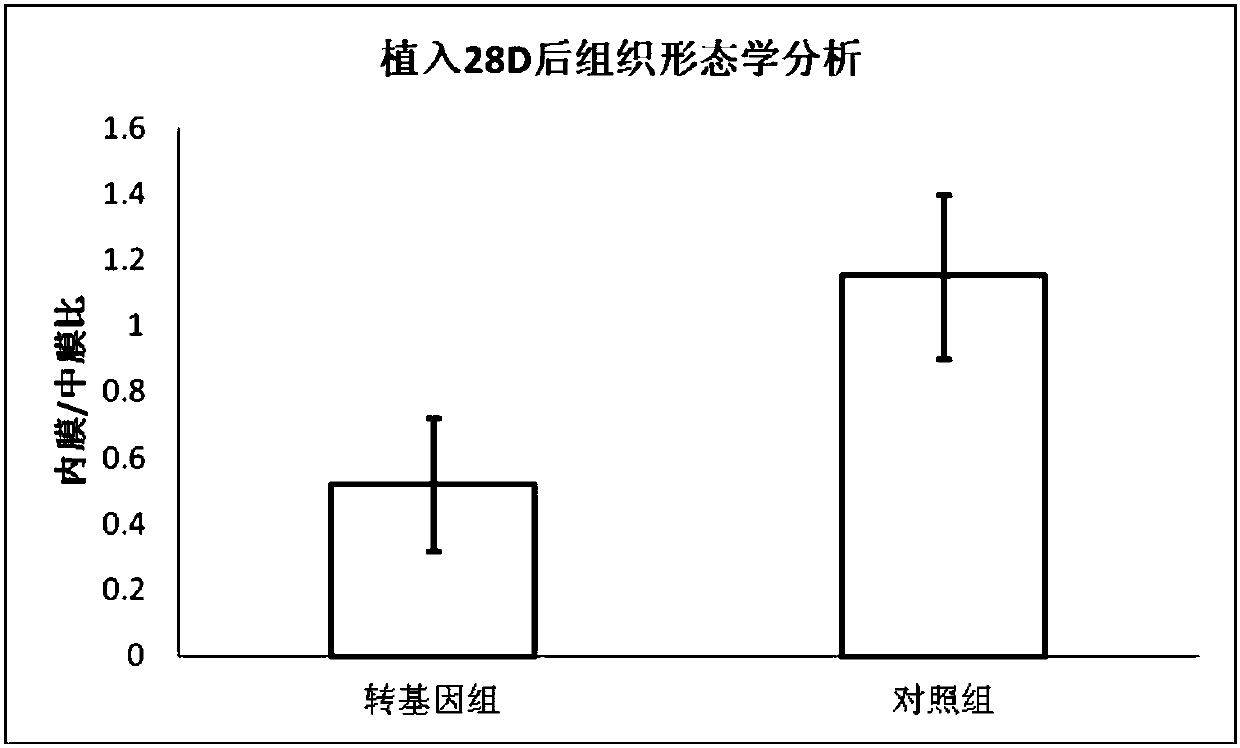

Drug-loaded balloon and preparation method thereof

ActiveCN109966564AImprove protectionImprove solubilityBalloon catheterSurgeryPolyvinyl alcoholPolyethylene glycol

The invention relates to a drug-loaded balloon. The drug-loaded balloon comprises a balloon, as well as a drug-loading layer and a protective layer which are sequentially stacked on the outer surfaceof the balloon; the drug-loading layer contains genes, and is covered with the protective layer; and the material of the protective layer is at least one selected from polyvinyl alcohol, polyvinylpyrrolidone, chitosan, hydroxypropyl-beta-cyclodextrin, hydroxyethyl cellulose, sodium carboxymethylcellulose, dextran, gum arabic, sodium alginate, collagen, soybean protein and polyethylene glycol stearate. The protective layer is capable of relatively well protecting the drug-loading layer, thereby avoiding excessive loss of the genes during delivery; moreover, the material of the protective layeris at least one selected from the aforesaid substances, so that, the protective layer can rapidly dissolve or fall off when the drug-loaded balloon expand upon arrival of the drug-loaded balloon at alesion site, thereby allowing rapid release of the genes.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

Production method of fatty livers

The invention discloses a production method of fatty livers, comprising the following steps: (1) preparing the following materials: primary materials: 15000g of fresh fatty livers of geese or ducks, secondary material: 4215g of yellow rice wine and ingredients: 18765ml of water and 1235g of salt and other materials; (2) after cleaning the fresh fatty livers and storing the fresh fatty livers in a cold storage at 0-4 DEG C, sprinkling the wine on the fresh fatty livers to age the fresh fatty livers for 12h; (3) pouring the prepared ingredients into a vessel to be mixed uniformly and placing the aged fatty livers into the vessel to be cured at 0-4 DEG C for 12h; (4) adding 19215g of clear water to a heating kettle and cooking the fatty livers together with the curing liquid in the kettle and then cooling the cooked materials; (5) after cooling the processed fatty livers, cleaning and finishing the fatty livers and quickly freezing the fatty livers in a quick freezer at minus 30 DEG C until the center temperature of the fatty livers reaches minus 16 DEG C; and (6) vacuum packaging and storing the fatty livers. The fatty livers have the beneficial effects of ensuring cardio-cerebrovascular health and delaying aging, have added value more than doubling that of the frozen fresh fatty livers and have remarkable effects.

Owner:JILIN ZHENGFANG AGRI & ANIMAL HUSBANDRY

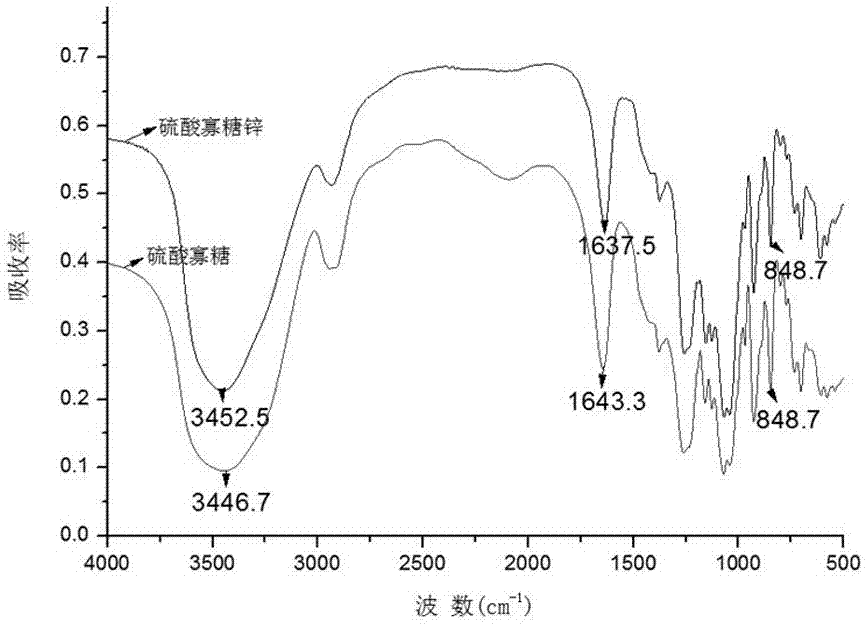

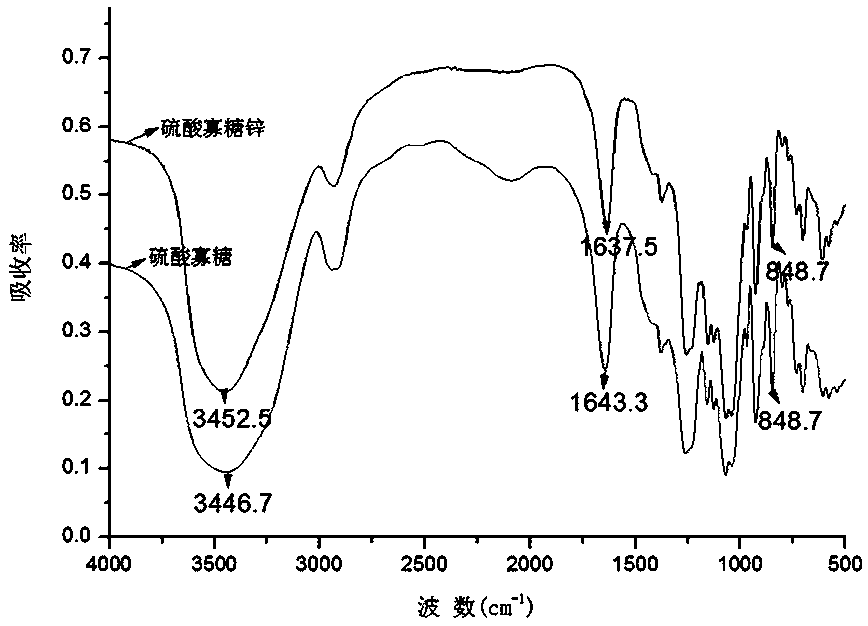

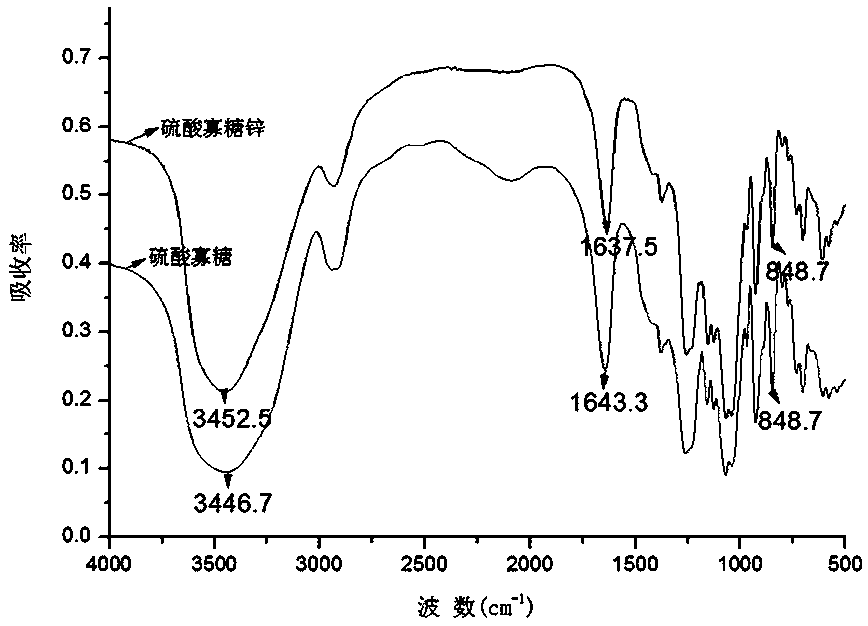

Sulfated oligosaccharide zinc and preparation method thereof

The invention relates to sulfated oligosaccharide zinc and a preparation method thereof. The sulfated oligosaccharide zinc is prepared by taking dried frond of muriculate eucheuma as a raw material through process links of carrying out alkali treatment, extracting sulfated polysaccharide, preparing sulfated polysaccharide powder, preparing sulfated oligosaccharide powder, carrying out zinc impregnation, carrying out three-grade ultrafiltration separation, vacuum concentration, spray drying and the like. The sulfated oligosaccharide zinc prepared by the preparation method provided by the invention has high zinc content and relatively high content of sulfate groups, so that the sulfated oligosaccharide zinc has good physiological activity. The sulfated oligosaccharide zinc and the preparation method thereof have the advantages that the technology is advanced and reasonable, a processing process has strong controllability and expected economic benefits are good.

Owner:FUJIAN AGRI & FORESTRY UNIV

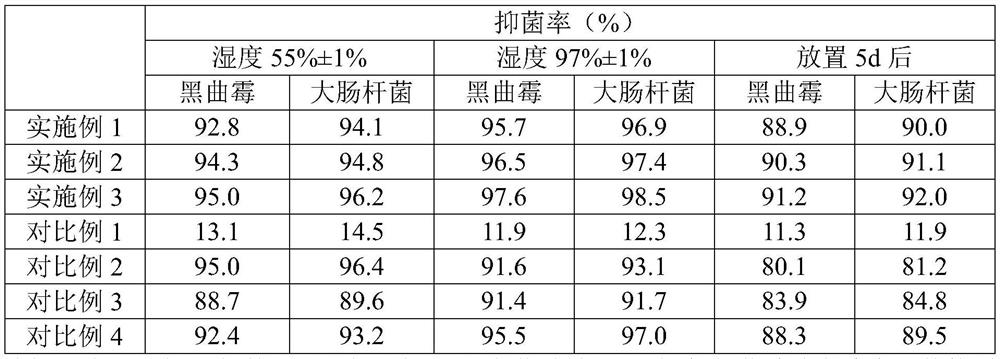

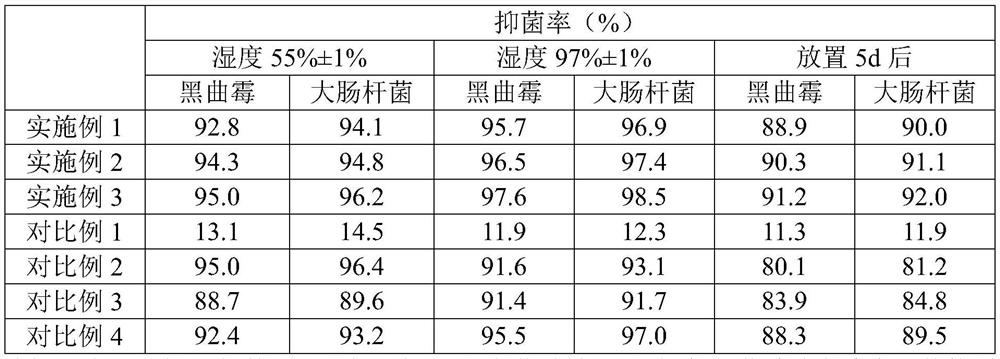

Aluminum foil lining paper with damp-proof and antibacterial functions and preparation method thereof

ActiveCN112127212AAvoid excessive lossesMeet the needs of anti-mildewFlexible coversWrappersPapermakingAntibacterial agent

The invention relates to the technical field of papermaking, and discloses aluminum foil lining paper with damp-proof and antibacterial functions and a preparation method of the aluminum foil lining paper. The aluminum foil lining paper is prepared from the following raw materials in parts by weight: 40-50 parts of softwood pulp, 50-60 parts of hardwood pulp, 15-25 parts of talcum powder, 20-25 parts of aluminum sulfate, 18-23 parts of alkenyl succinic anhydride and 5-8 parts of calcium oxide-sodium alginate / bletilla striata polysaccharide-liquorice essential oil microcapsules. In the preparation process, the calcium oxide- sodium alginate / bletilla striata polysaccharide-liquorice essential oil microcapsules are added into a sizing liquid. The calcium oxide-sodium alginate / bletilla striatapolysaccharide-liquorice essential oil microcapsules are used as a damp-proof and antibacterial agent, so that the mildew-proof requirements of the aluminum foil lining paper and cigarettes in low-humidity and high-humidity environments can be met, excessive loss of liquorice essential oil in the low-humidity environment can be prevented, and the antibacterial and mildew-proof effects of the aluminum foil lining paper are more lasting.

Owner:浙江哲丰新材料有限公司

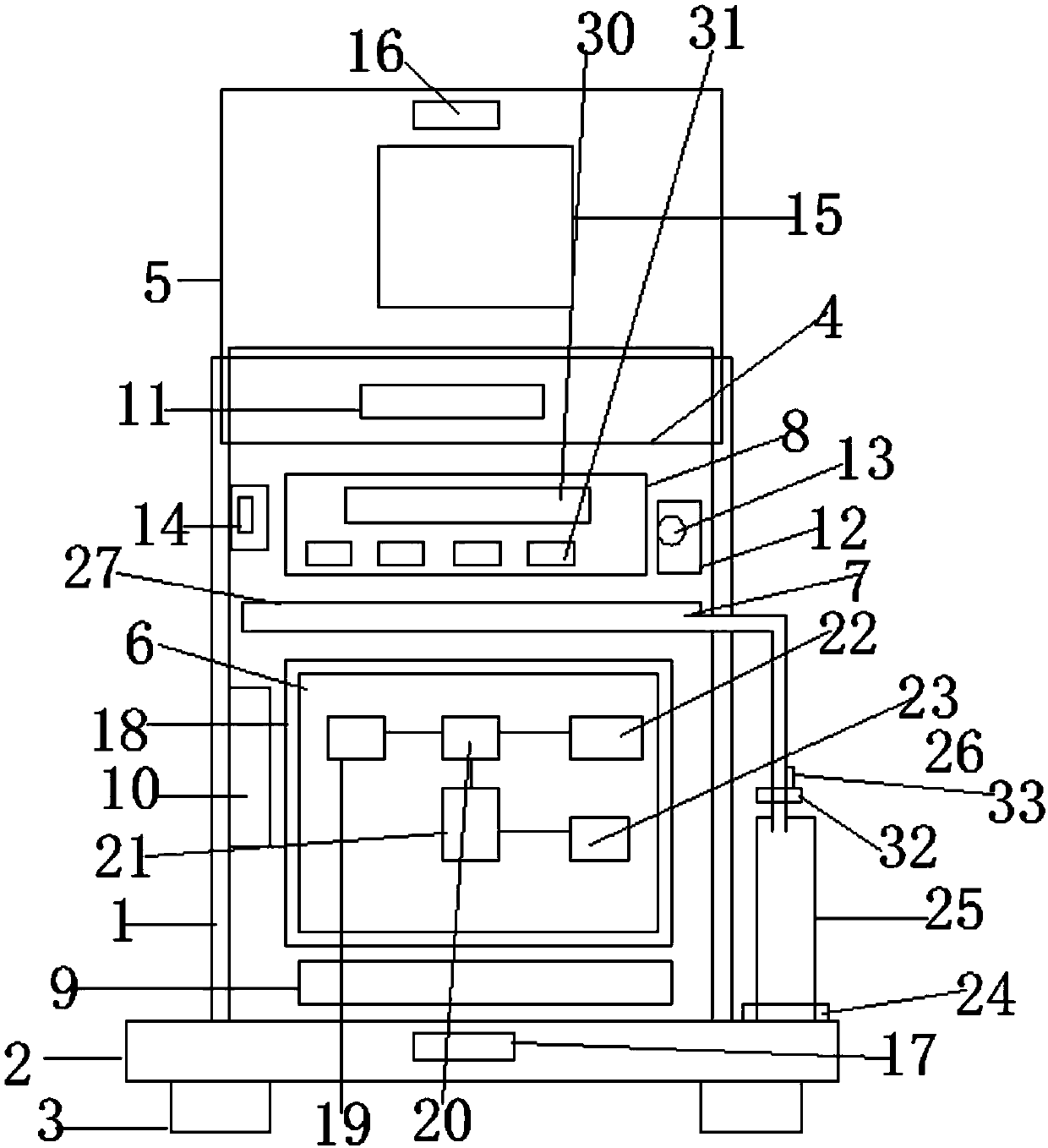

Multifunctional power distribution network automation device

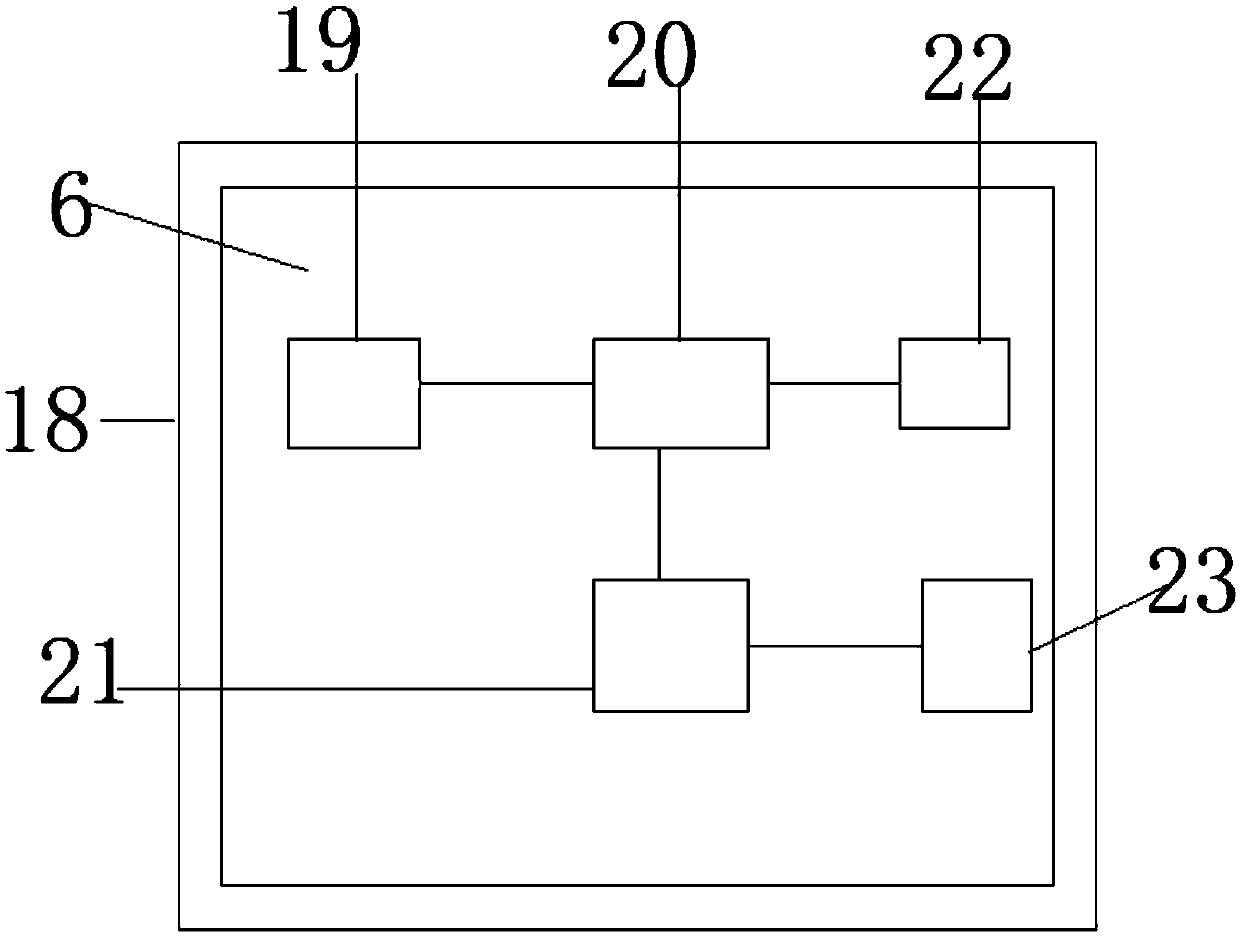

InactiveCN108683094AAvoid excessive lossesAvoid big lossesBoards/switchyards circuit arrangementsSubstation/switching arrangement cooling/ventilationLiquid-crystal displayElectrical and Electronics engineering

The invention provides a multifunctional power distribution network automation device, which relates to the technical field of power distribution network automation devices. The multifunctional powerdistribution network automation device comprises a box body, a fixing base and a clamping base, wherein the box body is provided with a door rod, an automatic circuit board, a fire extinguishing device, an operation table, a power distribution disc, a heat radiating device, a box door fixing block, an alarm sensing device, and a switch; the alarm sensing device is provided with an alarm machine, and the box door is provided with a glass door body, the box door is provided with a buckle, and the fixing base is provided with a buckle joint; the automatic circuit board is provided with a fireproof shell, a sensor, an information collecting and processing module, a communication module, an information feedback module and a display module. The invention is advantageous in that the information collecting and processing module and the communication module, the information feedback module and the display module are arranged on the automatic circuit board, and the information can be transmittedto the liquid crystal display of the operation table in time; the problem can be found and solved in time, and the glass door body is arranged through the box door, and thereby the condition inside the box body can be observed without opening the box door, and the use is simple and convenient.

Owner:广州百兴网络科技有限公司

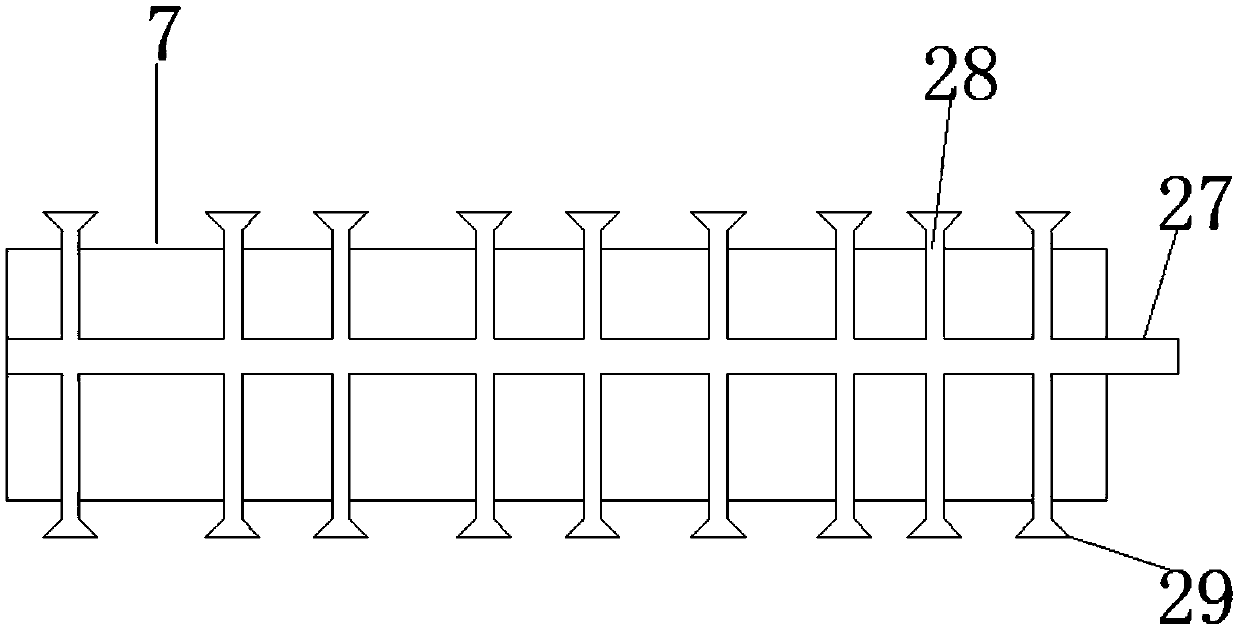

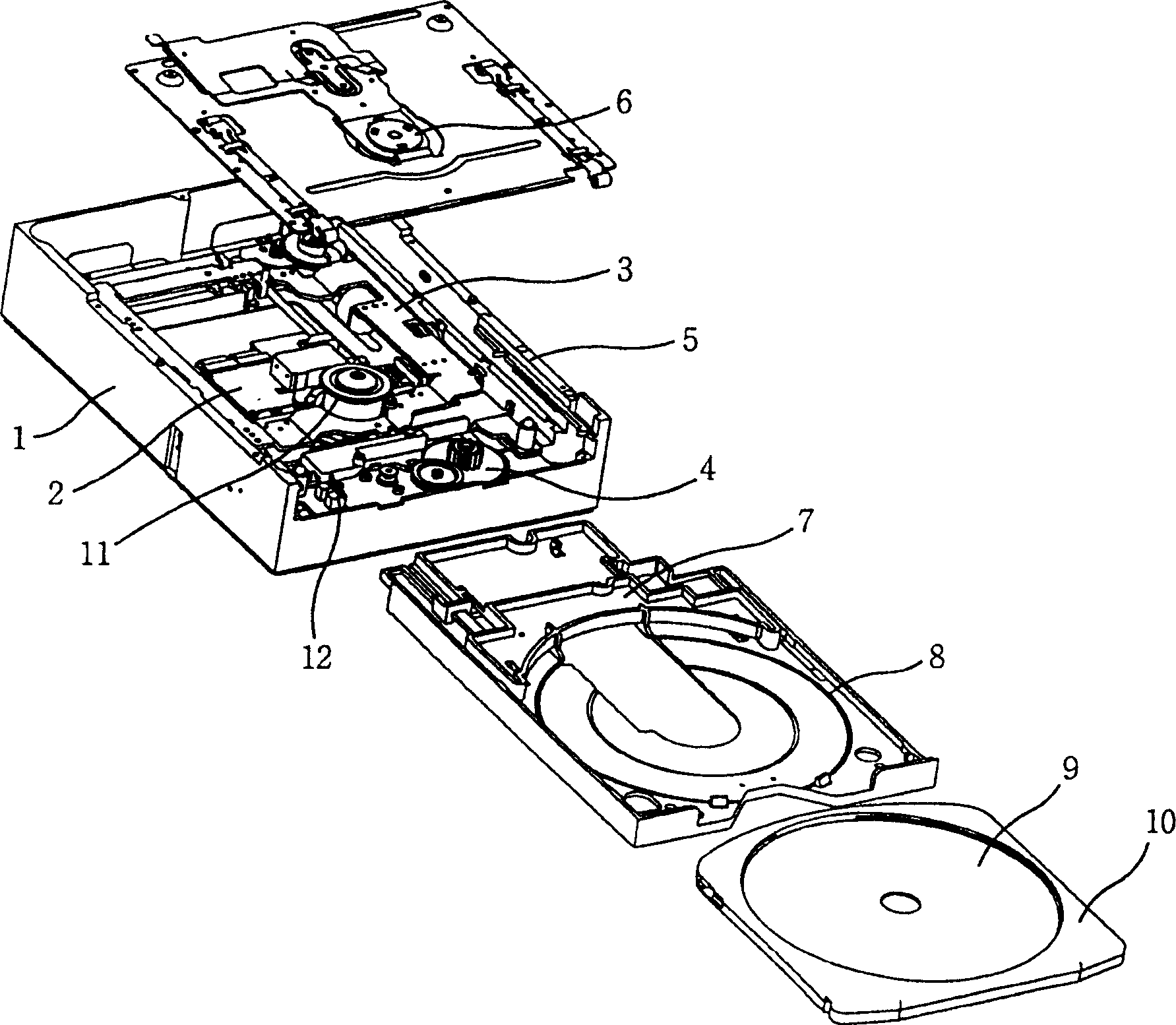

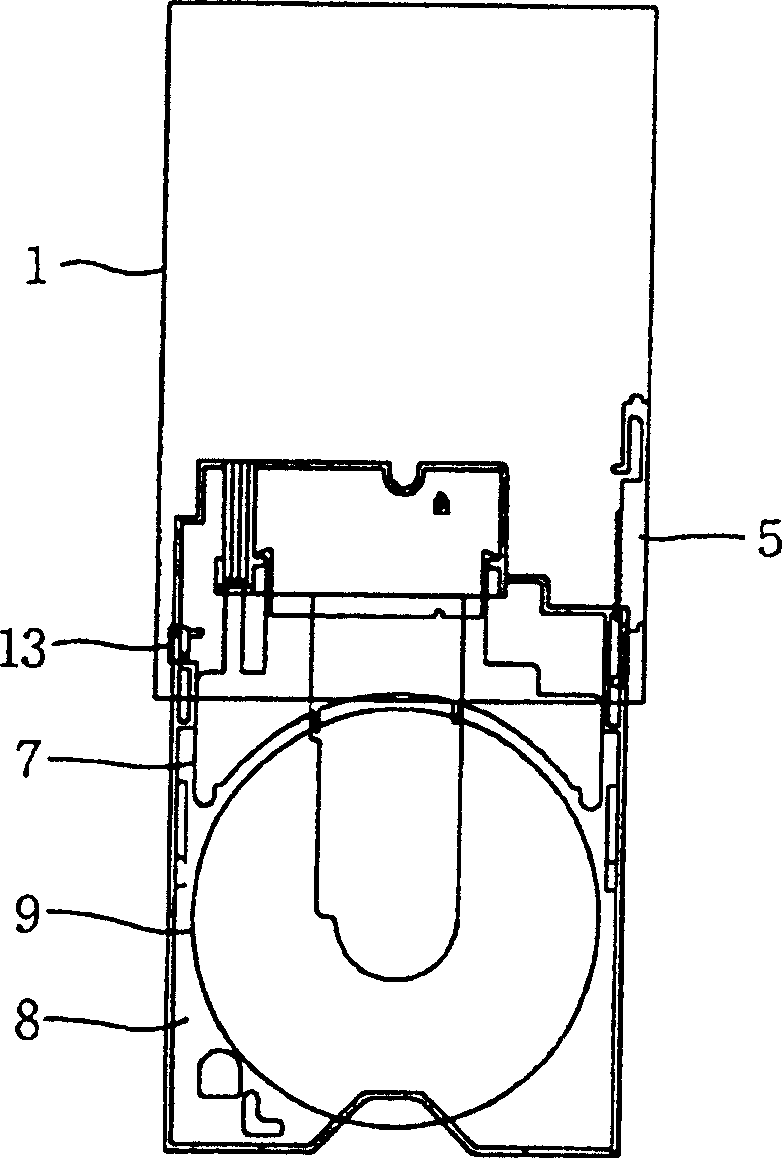

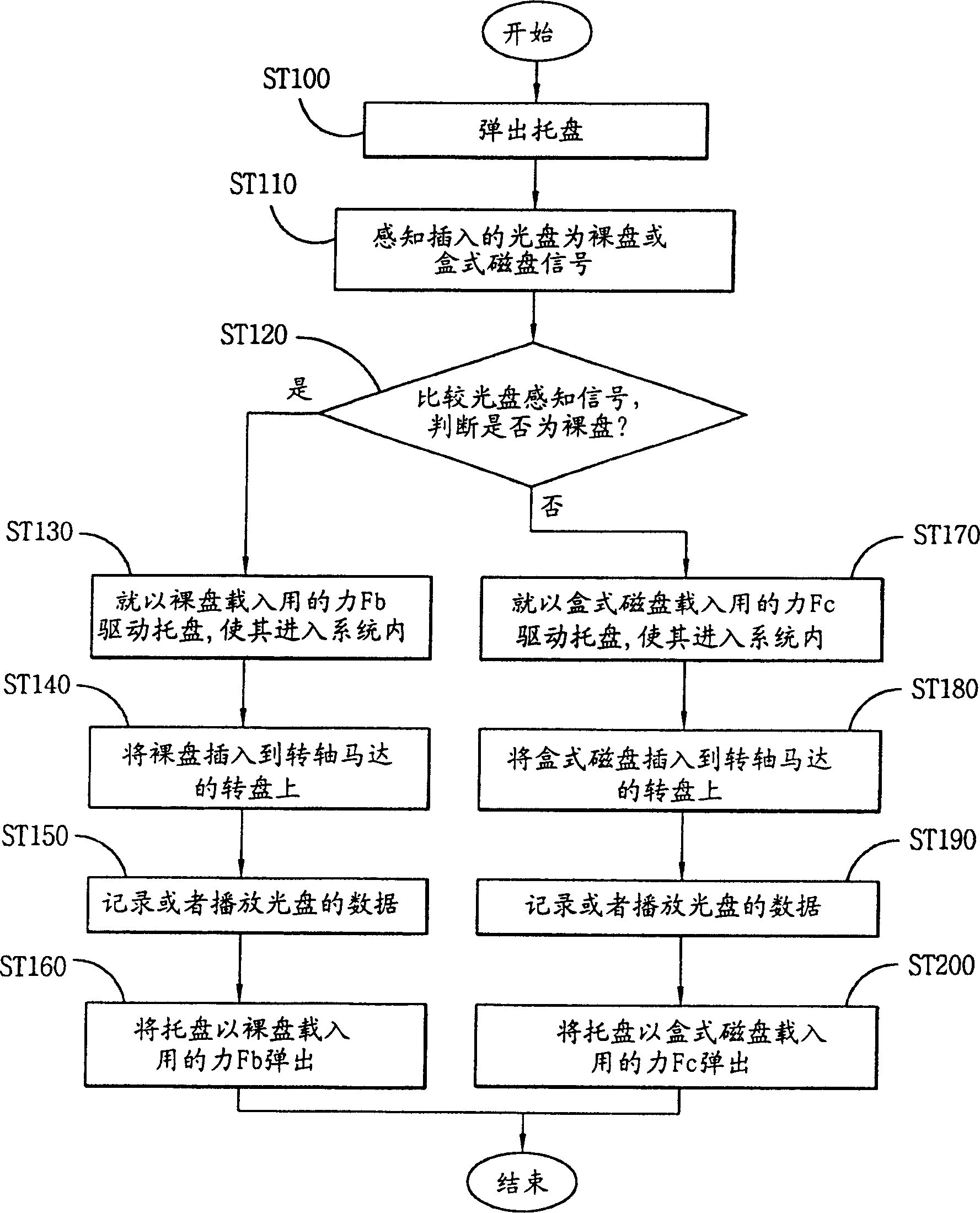

Optical disk loading method of optical disk drive and optical disk discriminating device

InactiveCN1691172AAvoid excessive impactSave spaceRecord information storageDisk enclosureOptical disc drive

The invention concerns CD load method and its CD distinguish device for CD driver, which comprises, bounce out disk; sense the CD inserted is empty disk or cartridge disk; compare CD sensing signal; if it is empty disk, use force Fb loaded CD to drive disk, push it in system and insert to rotating-disk of rotation shaft motor, then record or play data on CD, finally use force Fb loaded CD to bounce out it; if it is cartridge disk, execute similarly operation aforementioned with force Fc loaded cartridge disk. This invention can prevent the over impact when inserting empty disk and over loss of system electric quantity, realize thinlization for CD cabin; besides, support of fixed cartridge disk box also has the function as CD distinguish device.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

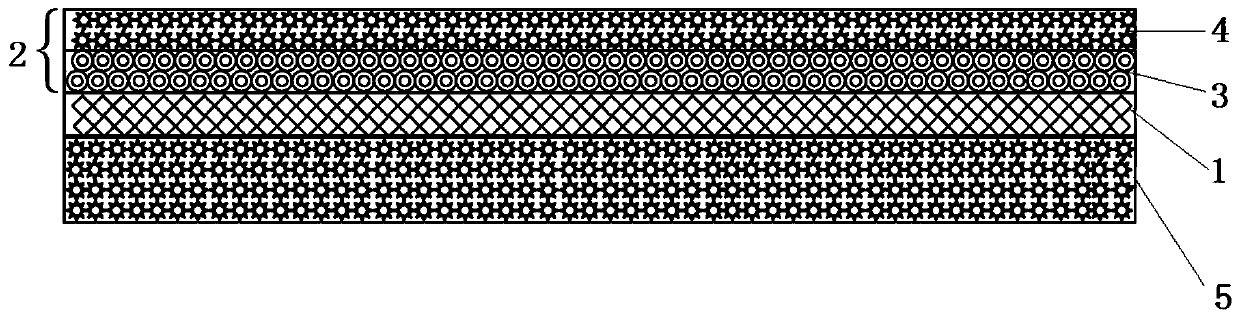

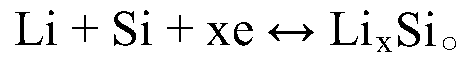

Composite coating diaphragm for lithium ion battery and lithium ion battery

PendingCN111211278ASimple structureImprove securityCell seperators/membranes/diaphragms/spacersSecondary cellsMetallic lithiumPhysical chemistry

The invention relates to a composite coating diaphragm for a lithium ion battery and a lithium ion battery and belongs to the technical field of lithium ion batteries. The composite coating diaphragmfor the lithium ion battery comprises a diaphragm base material and a composite coating arranged on one surface of the diaphragm base material; the composite coating comprises a silicon dioxide coating arranged on the diaphragm base material and a first boehmite coating arranged on the silicon dioxide coating. The silicon dioxide coating of the composite coating diaphragm for the lithium ion battery can avoid the problems of performance attenuation and safety of the battery due to the fact that the diaphragm is punctured after lithium dendrites continuously and quickly grow; the first boehmitecoating which coats on the surface of the silicon dioxide coating prevents the silicon dioxide from reacting with metal lithium on the surface of a negative electrode before the lithium dendrites appear, and therefore, the excessive loss of the effective lithium of the battery can be prevented, and the further growth of the lithium dendrites can be delayed, the service life of the battery is effectively prolonged, and the safety accidents of the battery are reduced.

Owner:CALB CO LTD +1

A kind of light-weight and high-strength exterior wall interior thermal insulation gypsum and preparation method thereof

Owner:CHONGQING JIANDA BUILDING MATERIAL

Production method of fatty livers

The invention discloses a production method of fatty livers, comprising the following steps: (1) preparing the following materials: primary materials: 15000g of fresh fatty livers of geese or ducks, secondary material: 4215g of yellow rice wine and ingredients: 18765ml of water and 1235g of salt and other materials; (2) after cleaning the fresh fatty livers and storing the fresh fatty livers in acold storage at 0-4 DEG C, sprinkling the wine on the fresh fatty livers to age the fresh fatty livers for 12h; (3) pouring the prepared ingredients into a vessel to be mixed uniformly and placing the aged fatty livers into the vessel to be cured at 0-4 DEG C for 12h; (4) adding 19215g of clear water to a heating kettle and cooking the fatty livers together with the curing liquid in the kettle and then cooling the cooked materials; (5) after cooling the processed fatty livers, cleaning and finishing the fatty livers and quickly freezing the fatty livers in a quick freezer at minus 30 DEG C until the center temperature of the fatty livers reaches minus 16 DEG C; and (6) vacuum packaging and storing the fatty livers. The fatty livers have the beneficial effects of ensuring cardio-cerebrovascular health and delaying aging, have added value more than doubling that of the frozen fresh fatty livers and have remarkable effects.

Owner:JILIN ZHENGFANG AGRI & ANIMAL HUSBANDRY

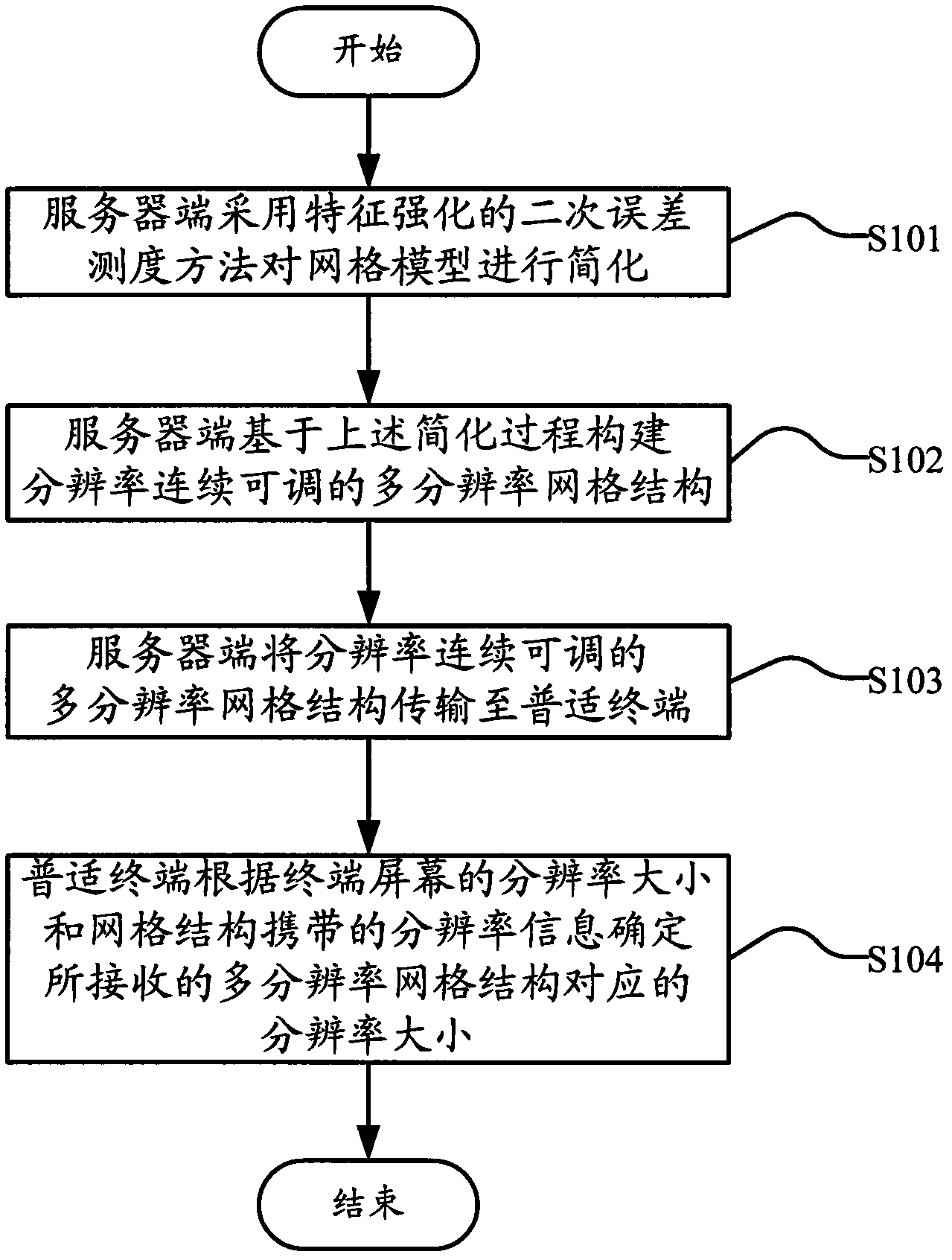

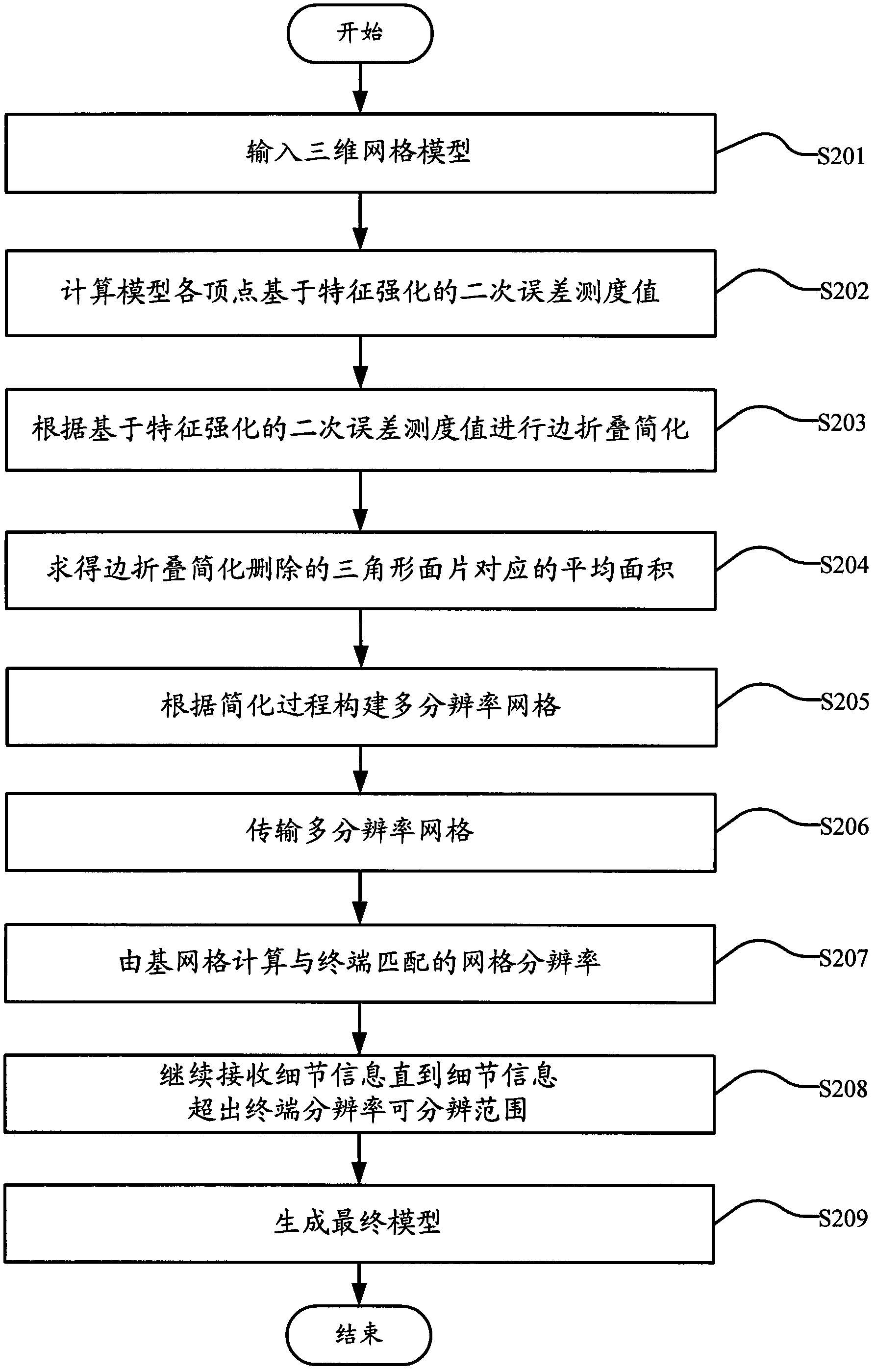

Pervasive-terminal-oriented continuous and multi-resolution encoding method of three-dimensional grid model

ActiveCN102324107BAvoid excessive lossesAvoid severe distortionImage generation3D modellingImage resolutionMulti resolution

Owner:SUN YAT SEN UNIV

How transistors are made

ActiveCN105590861BReduce thicknessAvoid excessive lossesSemiconductor/solid-state device manufacturingEtchingMetallic materials

Owner:SEMICON MFG INT (SHANGHAI) CORP

A Hyperpolarized Magnetic Resonance Imaging Method Based on Constant-Variable Angle Optimal Excitation

ActiveCN104181483BImprove signal-to-noise ratioQuality improvementMeasurements using NMR imaging systemsImaging qualityPhases of clinical research

The invention discloses a hyperpolarized magnetic resonance imaging method based on fixed-variable angle optimized excitation, and relates to the field of magnetic resonance imaging. The present invention combines the advantages of fixed-angle excitation and variable-angle excitation, and divides the excitation into two stages: fixed-angle excitation and variable-angle excitation, that is, the first n * The second excitation adopts the fixed-angle excitation method, and the subsequent N‑n * The secondary excitation adopts the variable-angle excitation method (where N is the total number of excitations), and at the same time selects the appropriate fixed-angle excitation parameters, so that the reconstructed MR image has higher SNR and better image quality, and the algorithm is robust. And noise, artifacts, etc. are significantly reduced compared with the prior art.

Owner:武汉中科极化医疗科技有限公司

Method for removing SEI membrane on surface of metal lithium negative electrode

InactiveCN109980311ALower internal resistanceImprove performancePrimary cell maintainance/servicingFinal product manufactureButton batteryAlloy

The invention provides a method for removing an SEI membrane on a surface of a metal lithium negative electrode. A lithium manganese button cell which is just packaged is processed, the lithium manganese button cell mainly comprises a negative electrode plate, a positive electrode plate, a diaphragm and an electrolyte; the negative electrode plate is made of lithium or alloy thereof, the positiveelectrode plate takes MnO2 as a positive active material, the diaphragm is arranged between the negative electrode plate and the positive electrode plate, the electrolyte comprises lithium perchlorate, the lithium manganese button cell which is just packaged is placed for 40-50 hours in a static state, and pre-discharging processing is performed, so that the designed capacity of the cell is consumed by 2.5-3.0%. By the method, the problems that the same-type of lithium-MnO2 prepared in the prior art is relatively high in resistance, high in cell capacity consumption and poor in cell performance can be solved.

Owner:FUJIAN NANPING NANFU BATTERY

A kind of zinc sulfate oligosaccharide and preparation method thereof

Owner:FUJIAN AGRI & FORESTRY UNIV

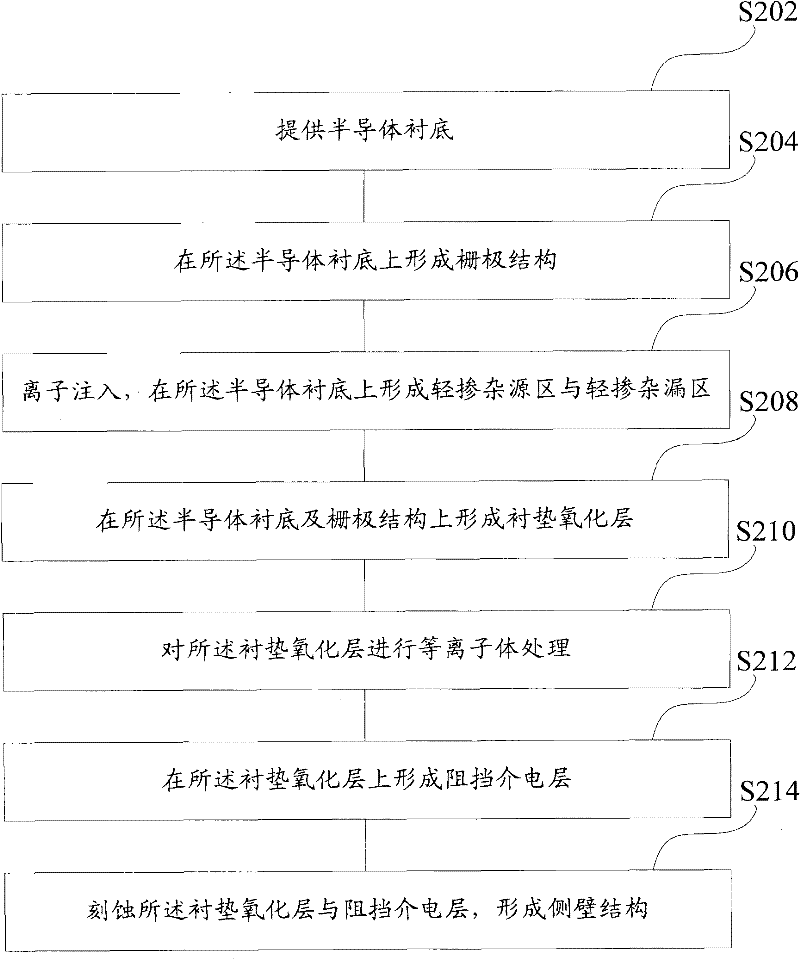

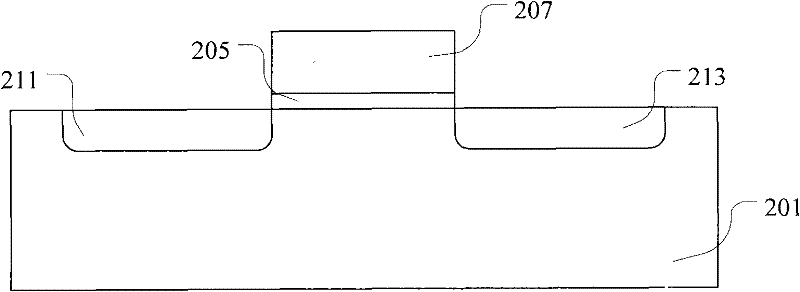

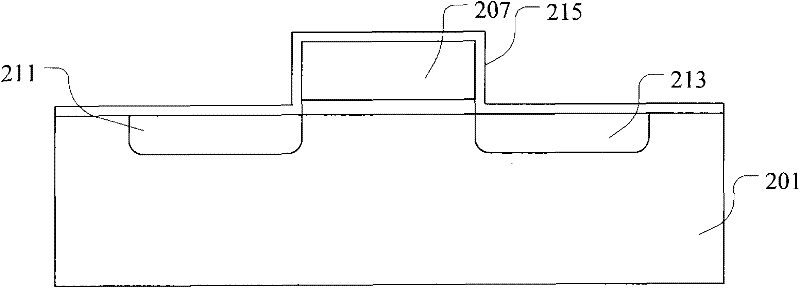

Method for manufacturing semiconductor device

InactiveCN102097319BReduced hydrogen contentQuality improvementSemiconductor/solid-state device manufacturingDevice materialHydrogen content

The invention discloses a method for manufacturing a semiconductor device, which comprises the following steps of: providing a semiconductor substrate, wherein the semiconductor substrate is N-type doped; forming a grid structure on the semiconductor substrate; performing ion implantation to form a light doped source region and a light doped drain region on the semiconductor substrate, wherein the implantation ions of the light doped source region and the light doped drain region are boron-containing ions; forming a gasket oxide layer on the semiconductor substrate; and performing plasma treatment on the gasket oxide layer. The plasma treatment can reduce the hydrogen content of the gasket oxide layer, and can also reduce diffusion of the doped ions of the light doped source region and the light doped drain region in subsequent annealing treatment to the gasket oxide layer so as to avoid over loss of the excessive ions.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A process for extracting perfume from dogwood kernels

The invention discloses a process for extracting perfume from dogwood nucleuses. The process comprises the following steps: preprocessing dogwood as a raw material, drying, refrigerating, grinding and distilling. According to the process, the extraction rate of spice substances in the dogwood is 57.9%-65.5%; the obtained perfume contains more than 60 flavor components and is easy to store, unique in aroma, specially aromatic, good in smell and free of any odor and is easily accepted by people, the oleic acid value is 17.5-18.8, side effects cannot be caused to skin, the aroma can be kept for a long time, and the perfume can serve as a chemical product and a food additive after being separated and purified.

Owner:江学忠

A kind of aluminum foil backing paper with moisture-proof and antibacterial function and preparation method thereof

ActiveCN112127212BAvoid excessive lossesMeet the needs of anti-mildewFlexible coversWrappersPapermakingAntibacterial agent

The invention relates to the technical field of papermaking, and discloses an aluminum foil backing paper with moisture-proof and antibacterial functions and a preparation method thereof. The aluminum foil backing paper includes the following raw materials in parts by weight: 40-50 parts of softwood pulp, 50-60 parts of hardwood pulp, 15-25 parts of talcum powder, 20-25 parts of aluminum sulfate, 18-23 parts of alkenyl succinic anhydride, 5~8 servings of calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules. During the preparation process, calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules are added to the sizing solution. The present invention adopts calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules as a moisture-proof antibacterial agent, which can meet the anti-mildew requirements of aluminum foil backing paper and cigarettes in low-humidity and high-humidity environments, and can prevent excessive licorice essential oil under low humidity. Loss, so that the antibacterial and anti-mildew effect of the aluminum foil backing paper is more durable.

Owner:浙江哲丰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com