Aluminum foil lining paper with damp-proof and antibacterial functions and preparation method thereof

A technology of aluminum foil backing paper and function, applied in pulp beating method, paper, papermaking, etc., can solve the problems of poor anti-mold effect of cigarettes, loss of anti-mold effect of cigarettes, etc., and achieve the effect of reducing the amount of mold, preventing mold, and accelerating volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

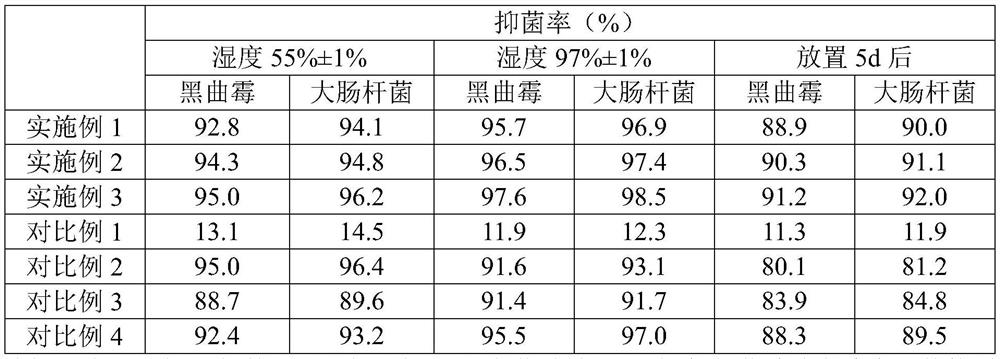

Examples

Embodiment 1

[0054] An aluminum foil backing paper with moisture-proof and antibacterial functions, comprising the following raw materials in parts by weight: 40 parts of softwood pulp, 60 parts of hardwood pulp, 15 parts of talcum powder, 20 parts of aluminum sulfate, 18 parts of alkenyl succinic anhydride, 5 parts Calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules.

[0055] The preparation method of above-mentioned calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules is as follows:

[0056] (a) dissolving Bletilla striata polysaccharide and sodium alginate in water at a mass ratio of 1:3.5 to prepare a mixed solution of sodium alginate Bletilla striata polysaccharide, wherein the mass fraction of sodium alginate is 1.8wt%;

[0057] (b) After mixing licorice essential oil with water, add Tween-80, fully mix, be mixed with the licorice essential oil emulsion that mass fraction is 5wt%; The mass ra...

Embodiment 2

[0072] An aluminum foil backing paper with moisture-proof and antibacterial functions, comprising the following raw materials in parts by weight: 45 parts of softwood pulp, 55 parts of hardwood pulp, 20 parts of talcum powder, 23 parts of aluminum sulfate, 20 parts of alkenyl succinic anhydride, 6.5 parts Calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules.

[0073] The preparation method of above-mentioned calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules is as follows:

[0074] (a) dissolving Bletilla striata polysaccharide and sodium alginate in water at a mass ratio of 1:3 to prepare a mixed solution of sodium alginate Bletilla striata polysaccharide, wherein the mass fraction of sodium alginate is 2 wt %;

[0075] (b) After mixing licorice essential oil with water, add Tween-80, fully mix, be mixed with the licorice essential oil emulsion that mass fraction is 4wt%; The mass ra...

Embodiment 3

[0090] An aluminum foil backing paper with moisture-proof and antibacterial functions, comprising the following raw materials in parts by weight: 50 parts of softwood pulp, 60 parts of hardwood pulp, 25 parts of talcum powder, 25 parts of aluminum sulfate, 23 parts of alkenyl succinic anhydride, 8 parts Calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules.

[0091] The preparation method of above-mentioned calcium oxide-sodium alginate / Bletilla striata polysaccharide-licorice essential oil microcapsules is as follows:

[0092] (a) dissolving Bletilla striata polysaccharide and sodium alginate in water at a mass ratio of 1:2.5 to prepare a mixed solution of sodium alginate Bletilla striata polysaccharide, wherein the mass fraction of sodium alginate is 2.3wt%;

[0093] (b) After mixing the licorice essential oil with water, add Tween-80, fully mix, and be mixed with the licorice essential oil emulsion whose mass fraction is 3wt%; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com