Manufacturing method of transistor

A manufacturing method and technology for transistors, which are used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as transistor failure and low yield, and achieve the effects of reducing thickness, reducing losses, and improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It is known from the background art that the transistors formed in the prior art are prone to failure and low yield.

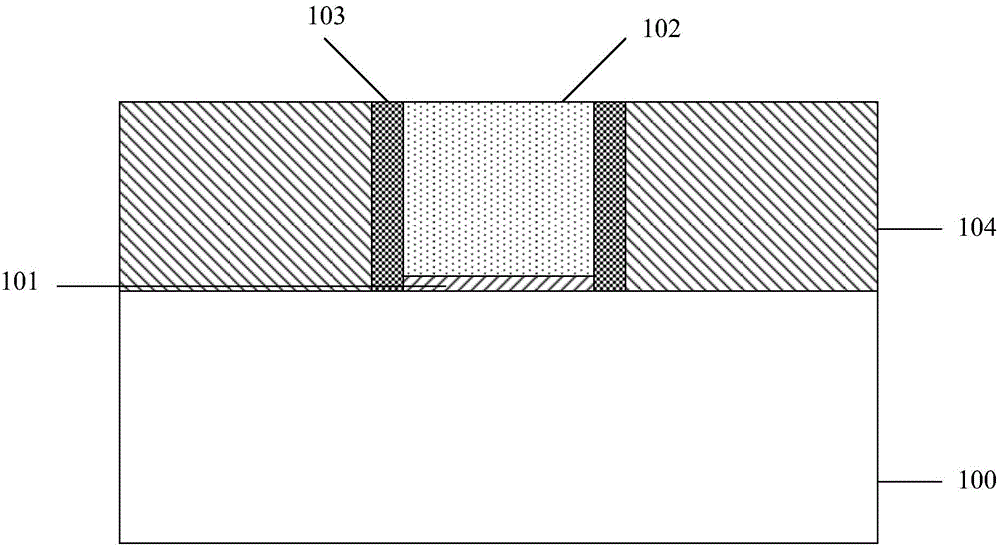

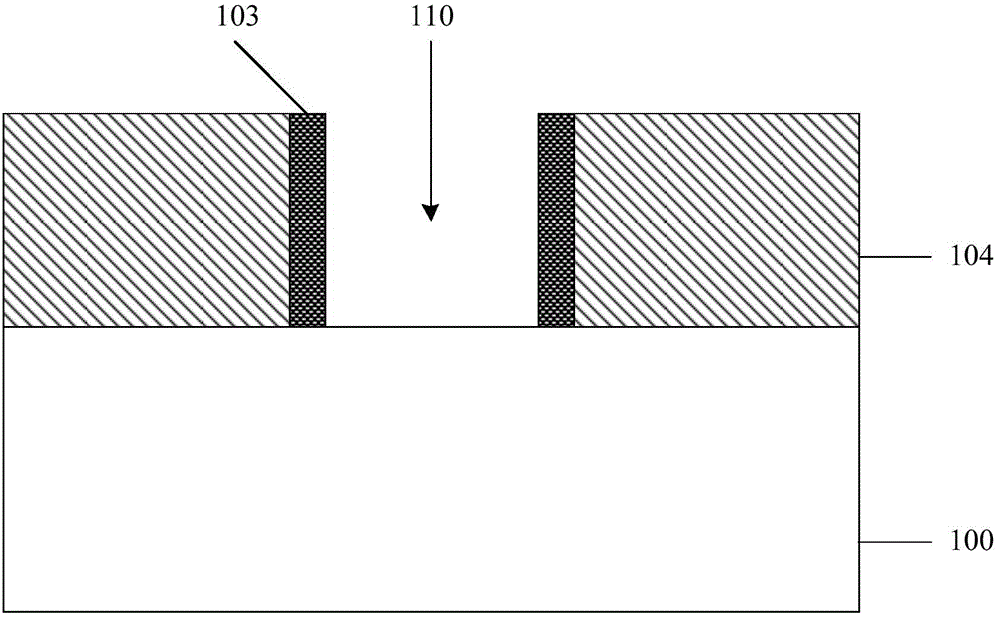

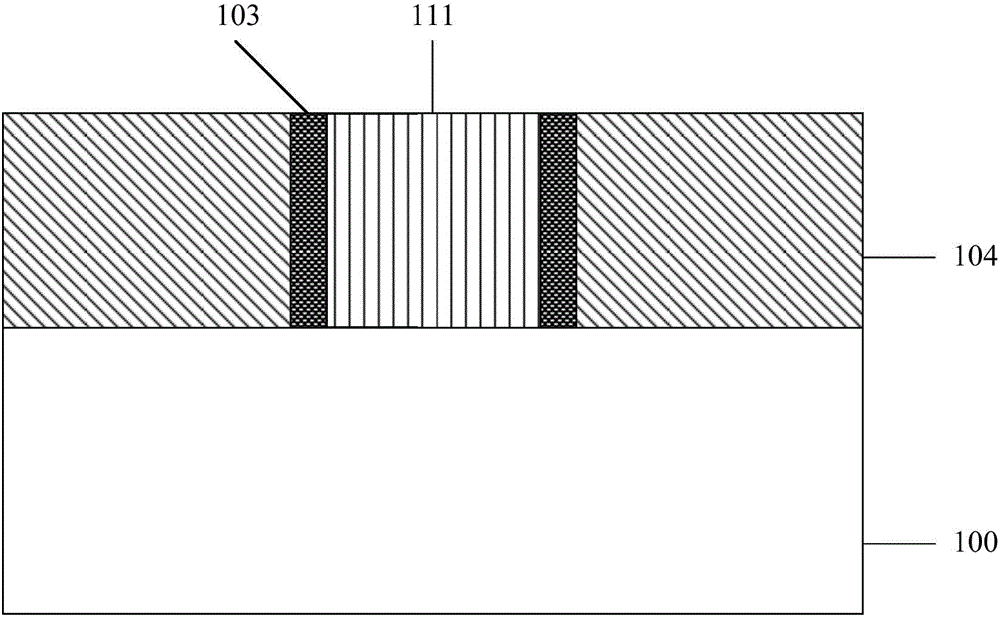

[0038] combine Figure 1 to Figure 3 The schematic diagram of the manufacturing method of the transistor in the prior art is shown, and the reasons for the failure of the transistor and the low yield are analyzed:

[0039] refer to figure 1 The material of the transistor protection layer 101 and the material of the interlayer dielectric layer 104 are oxides, and when the protection layer 101 is removed by cleaning with a diluted hydrofluoric acid solution, a part of the thickness of the interlayer dielectric layer 104 will also be consumed. Moreover, since the formation process of the protective layer 101 and the interlayer dielectric layer 104 is different (the method for forming the protective layer 101 is mostly a thermal oxidation process, and the method for forming the interlayer dielectric layer 104 is mostly a chemical vapor deposition process),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com