A vented single-screw extruder for preparing high-viscosity explosives by solvent method

A single-screw extruder, explosives technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of poor temperature exchange of materials, leakage of materials, and difficulty in cleaning residual materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

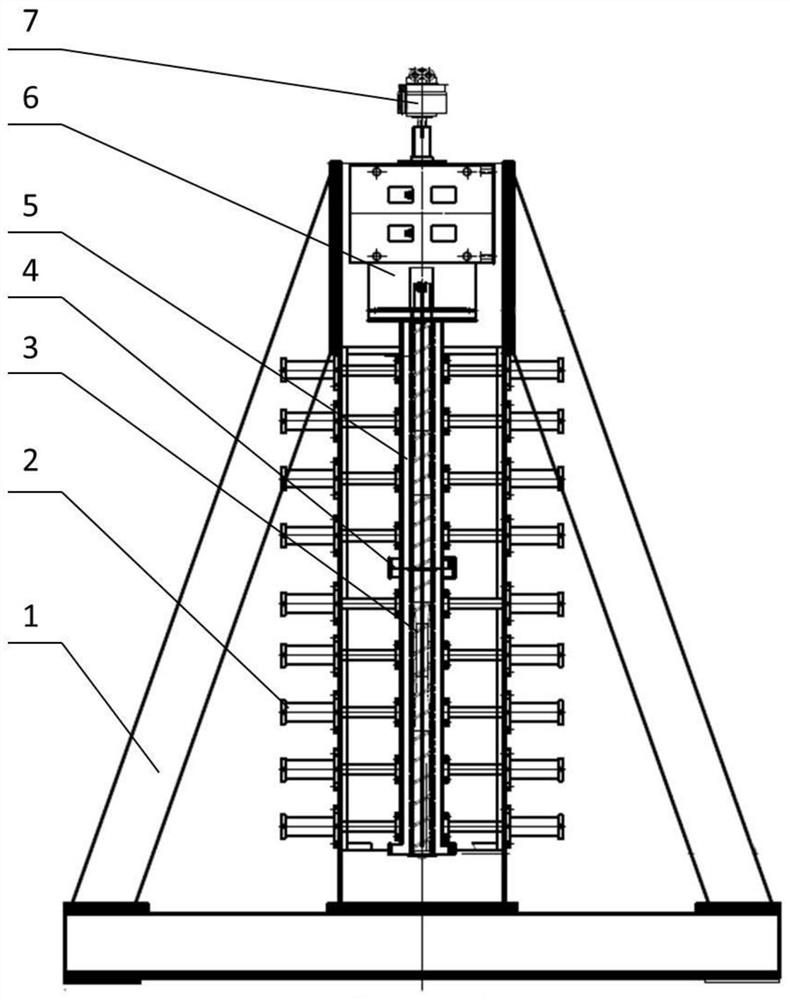

[0017] The vented single-screw extruder described in this embodiment is used for the preparation of high-viscosity propellants and explosives by the solvent method, and it is mainly used for compression-stretching molding of propellants with a solvent content of 30%.

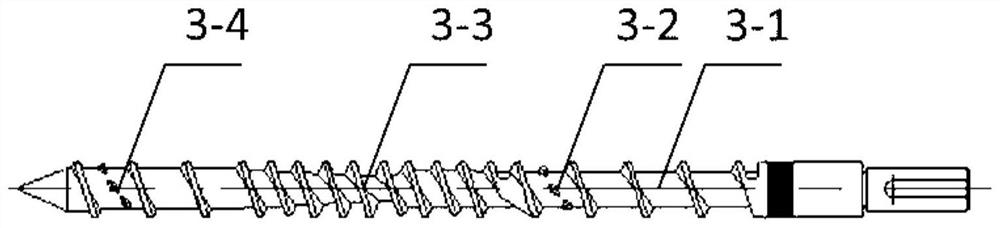

[0018] see figure 2 , the single screw has a conveying section, a mixing section 1, an exhaust section, and a mixing section 2, and cooling water is passed inside the screw; the mixing section 1 and the mixing section 2 are diamond-shaped pins arranged in a spiral; The groove depth of the exhaust section is three times the groove depth of the conveying section, and the exhaust section is a double thread; the length of the exhaust section is 3D.

[0019] see figure 1 , the barrel is a vertical barrel; the barrel is a radially split structure, and there is an exhaust port at the position corresponding to the barrel and the exhaust section of the screw, and the inner wall of the barrel on the side of the exhaust ...

Embodiment 2

[0021] The vented single-screw extruder described in this example is used for the preparation of high-viscosity propellants and explosives by the solvent method, and it is mainly used for compression-stretch molding of propellants with a solvent content of 50%.

[0022] see figure 2 , the single screw has a conveying section, a mixing section 1, an exhaust section, and a mixing section 2, and cooling water is passed inside the screw; the mixing section 1 and the mixing section 2 are diamond-shaped pins arranged in a spiral; The groove depth of the exhaust section is three times that of the conveying section, and the exhaust section is a double thread; the length of the exhaust section is 5D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com