High-viscosity heavy oil processing method

A processing method and heavy oil technology, applied in the petroleum industry, cracking, catalytic cracking, etc., can solve problems such as prolonging the production cycle, and achieve the effects of improving liquid yield, overcoming severe coking, and reducing coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

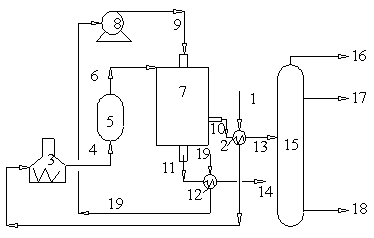

[0025]Carry out 4 groups of tests on the heavy oil visbreaking test device, are respectively embodiment 1, embodiment 2, embodiment 3, embodiment 4. The test device flow chart of embodiment sees figure 1 .

[0026] The heavy oil raw material enters from the top of the visbreaking tower after exchanging heat with the vis-reduced residual oil generated by the heat exchanger to 200-400°C; the catalytic flue gas raw material passes through the heat exchanger and reacts with the unstable gasoline and vis-reduced diesel oil After heat exchange to 200-300°C, enter the catalytic flue gas heating unit to heat to 350-900°C, then heat the catalytic flue gas and introduce it into the deoxidation reactor for deoxidation treatment, and control the oxygen content in the catalytic flue gas below 0.01-1wt%. The deoxidized catalytic flue gas enters the visbreaking tower; the heavy oil is in contact with the hot air of the catalytic flue gas at 350-900°C for at least 0.01-60 minutes in the visb...

Embodiment 1

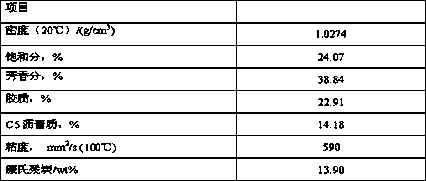

[0029] The feed oil used in Example 1, Example 2, Example 3, Example 4 and Comparative Example 1 is the same vacuum residue feed, and its kinematic viscosity at 100°C is 590mm 2 / s, the feed rate is 50kg / h, the specific properties are shown in Table 1. For other operating procedures, please refer to the descriptions in the specific embodiment section of this manual in conjunction with the accompanying drawings, see Table 2 for the main operating conditions, and see Table 3 for product distribution.

[0030] Table 1 Properties of raw oil

[0031]

[0032] Table 2 Main operating conditions

[0033]

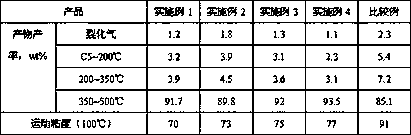

[0034] Table 3 Product Distribution

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com