A method for reducing viscosity of heavy oil

A heavy oil and visbreaking technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, cracking, etc., can solve the problems of prolonging the production cycle, achieve the effects of increasing liquid yield, increasing liquid product yield, and reducing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

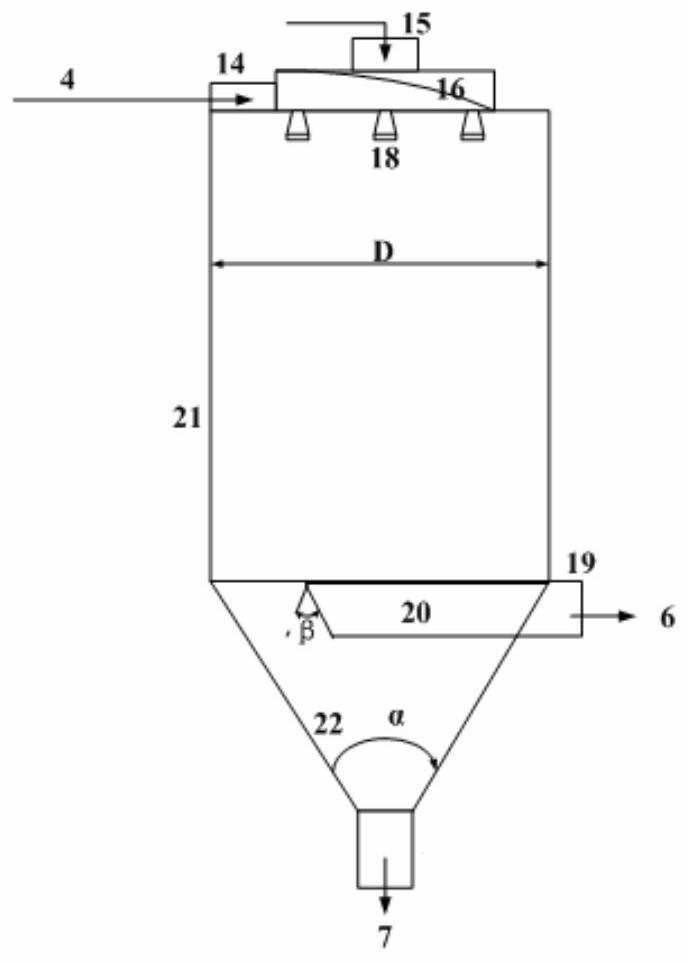

[0053] According to a preferred embodiment of the present invention, the included angle β of the herringbone baffle 20 is 10-150°, preferably 30-100°.

[0054] According to a preferred embodiment of the present invention, the cone angle α of the lower cone collection zone 22 is 10-150°, preferably 70-120°; more preferably, the aspect ratio of the straight cylinder reaction zone (21) is 2-10:1, more preferably 2-8:1.

[0055] In the present invention, it is not limited to the form of the spray visbreaking tower, as long as the heavy oil visbreaking unit conforms to the direct contact heat transfer form of liquid droplets and hot air.

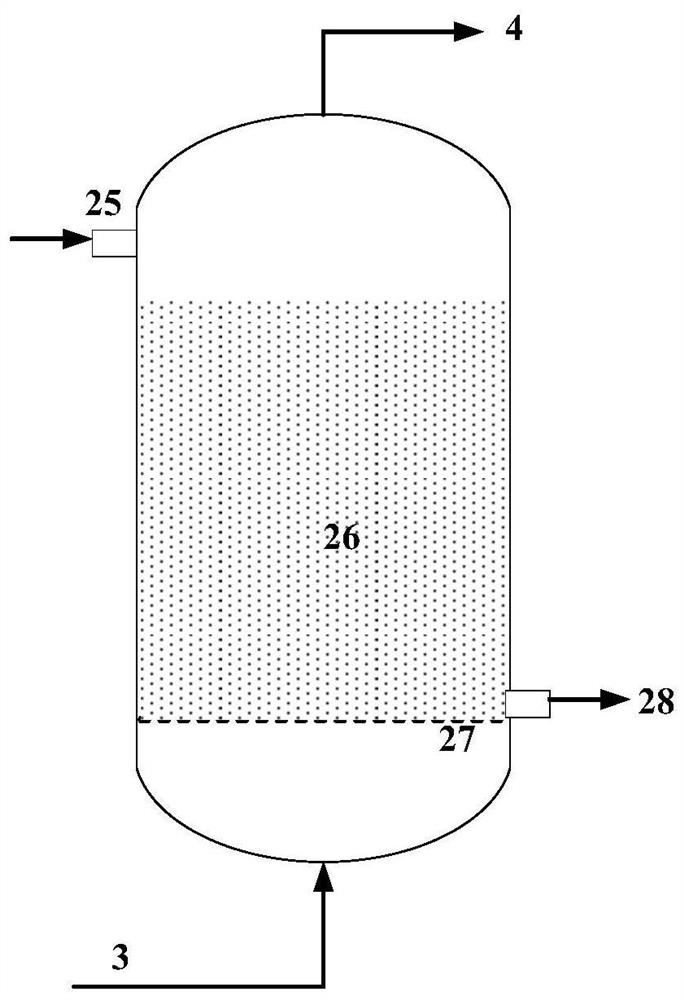

[0056] According to the method of the present invention, the equipment further includes a fractionation unit d connected in series with the heavy oil visbreaker unit c, and the fractionation unit d is used for separating the visbroken product from the heavy oil visbreaker unit c.

[0057] According to the method of the present invention, the equ...

Embodiment

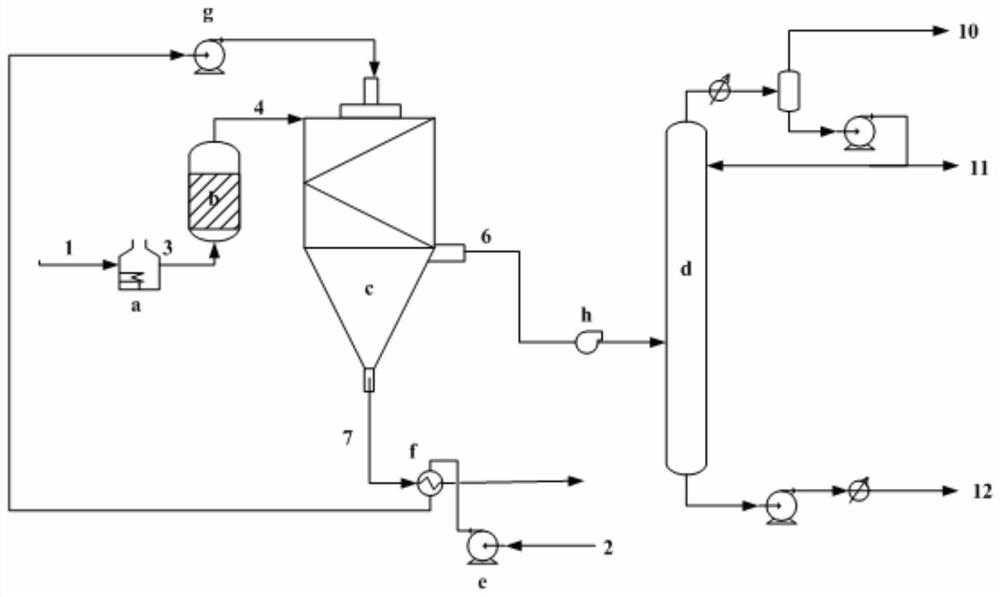

[0101] Three groups of tests were carried out on the heavy oil visbreaking medium-scale test device, namely Example 1, Example 2, and Example 3. The test device flow chart of embodiment sees figure 1 .

[0102] Follow the steps below (eg figure 1 ):

[0103] 1. After the heavy oil is preheated to 150-350°C through the heat exchanger f (200°C in Example 1, 250°C in Example 2, and 280°C in Example 3), it enters from the top of the spray vis-reducing tower, and is sprayed by atomization The nozzle disperses into small droplets of 20-600μm.

[0104] 2. The small droplets are in contact with 400-900°C high-temperature deoxygenation hot air (450°C in embodiment 1, 500°C in embodiment 2, and 600°C in embodiment 3) in the spray vis-reducing tower for 0.01-60min (the embodiment 1 is 600°C). 10min, embodiment 2 is 8min, embodiment 3 is 5min), the liquid droplet takes place thermal cracking reaction rapidly in the hot blast, after the reaction, the remaining viscosity-reducing residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com