A water-saving washing cycle system

A circulation system and water-saving technology, applied in the direction of textiles and papermaking, textile material treatment, continuous treatment of textile materials, etc., can solve the problems of energy saving, large power consumption, long technical route, etc., and achieve improved water washing Effect, the effect of water storage increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

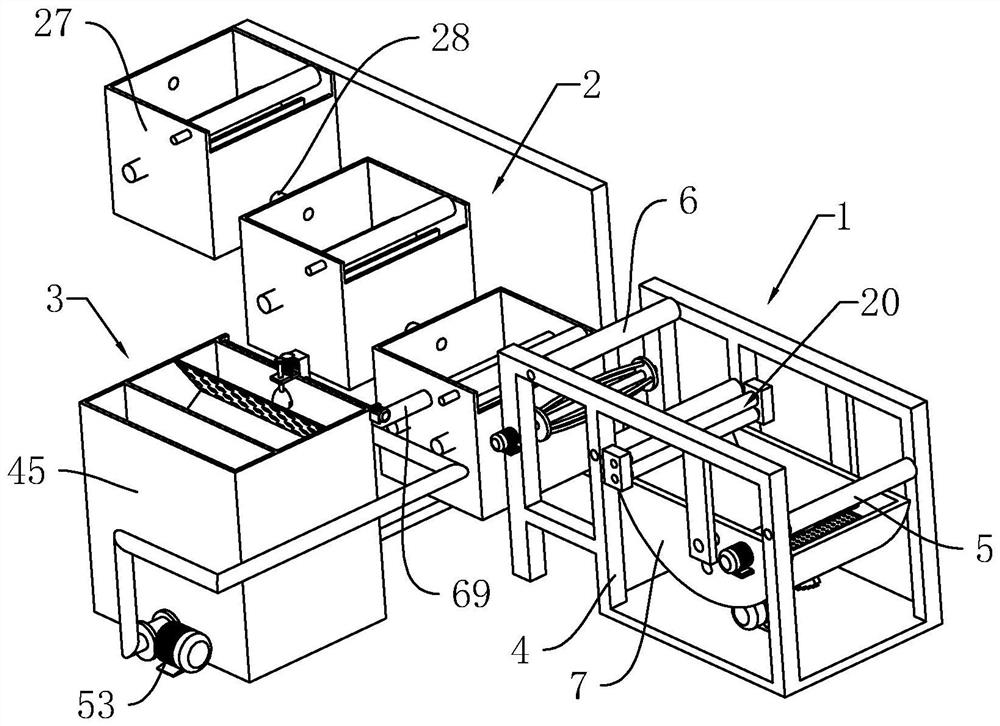

[0041] refer to figure 1 , is a water-saving washing circulation system disclosed in the present invention, comprising a feeding mechanism 1, a washing mechanism 2 and a circulation mechanism 3 arranged in sequence, and the cloth is initially cleaned after passing through the feeding mechanism 1, and then sent to the washing mechanism 2 for further cleaning. Multiple times of deep cleaning, the waste water generated during the cleaning process enters the circulation mechanism 3 for filtration treatment, and then passes into the washing mechanism 2 to realize the reuse of waste water, achieving the effect of high efficiency and water saving, which is in line with the concept of green development.

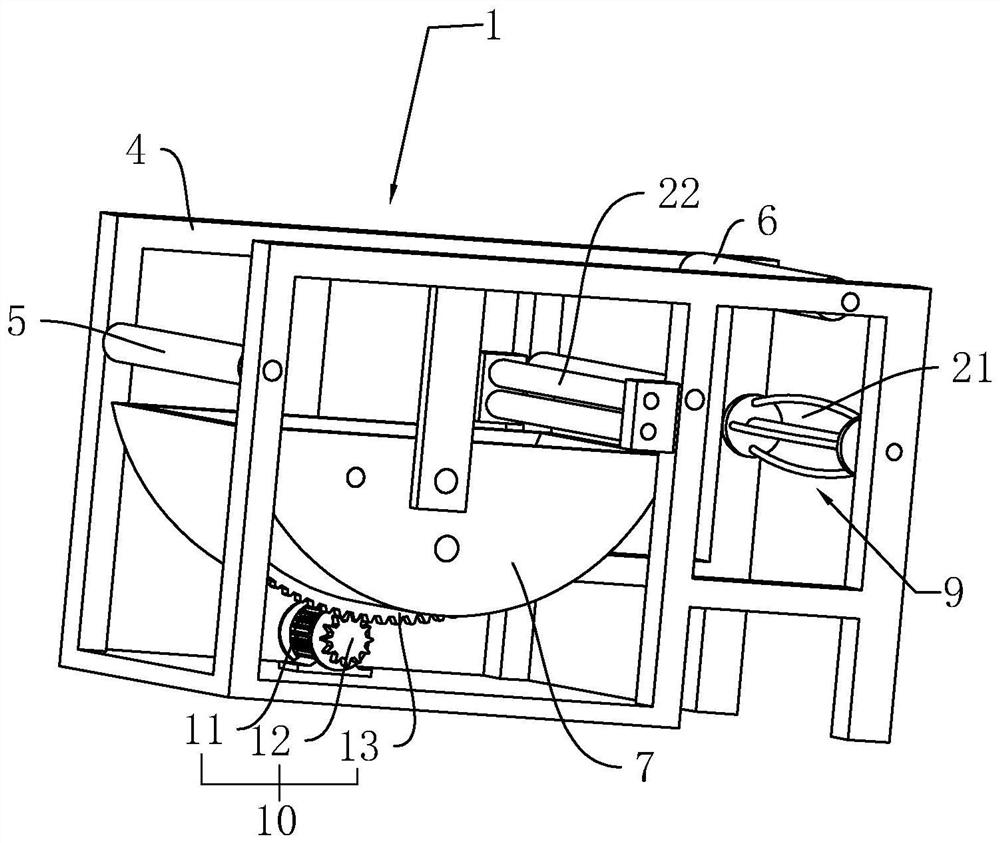

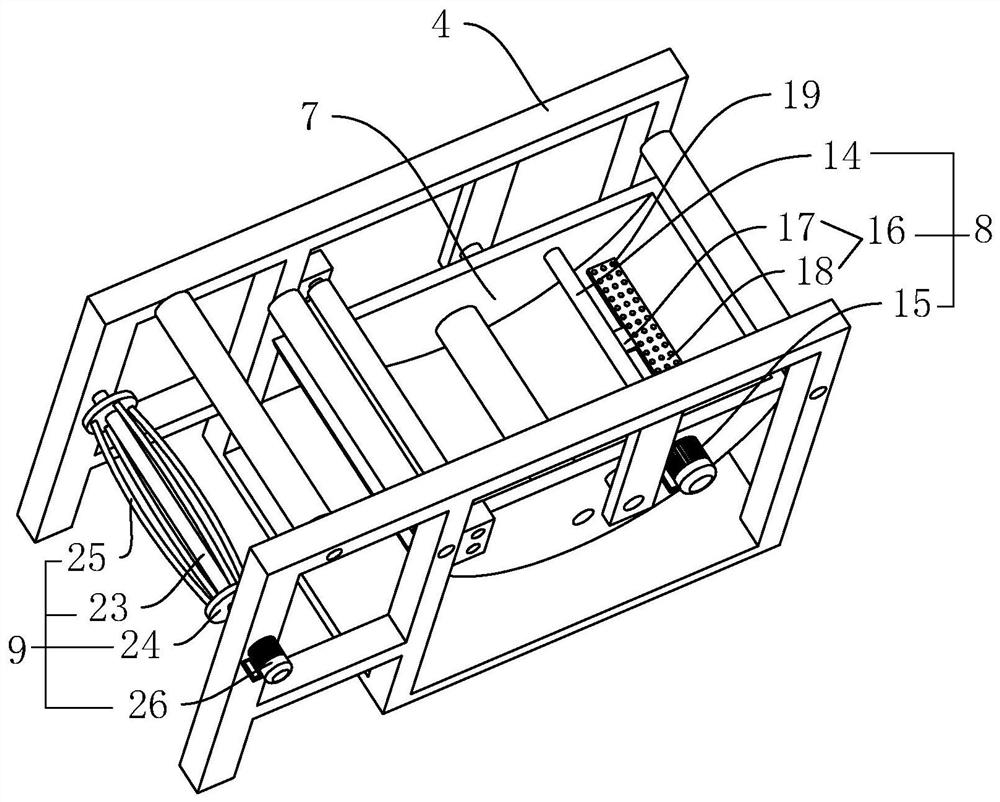

[0042] like figure 2 and image 3 As shown, the feeding mechanism 1 includes a frame 4, a feed roller 5 and a discharge roller 6 that are respectively rotated at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com