Water surface spilled oil recovery device

A technology of oil spill recovery and recovery device, which is applied in the direction of general water supply saving, cleaning of open water surface, water conservancy projects, etc. It can solve the problems of difficulty in meeting actual needs and low recovery efficiency, and achieve simple structure, strong adaptability and good recovery effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

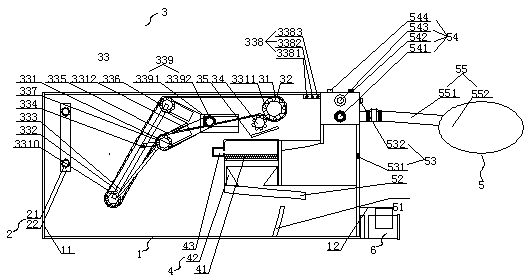

[0015] Such as figure 1 As shown, a water surface oil recovery device of the present invention is mainly composed of a box body 1, a baffle plate 2, a transmission device 3, a filter device 4, a recovery device 5, and a power device 6. The front of the box is a water inlet 11, the inside of the box is equipped with a baffle plate 2, a transmission device 3, a filtering device 4 and a partial recovery device 5, and a power unit 6 is installed at the rear of the box. The baffle plate 2 is a straight plate 22 fixed by bolts 21 , and is located at the front upper part of the box body 1 . The transmission device 3 is located behind the baffle plate 2 and is composed of an oil-absorbing felt 31, a recovery chain 32, a driving device 33, an oil squeezing gear 34, and an oil guide plate 35; the driving device 33 is composed of a bifurcated connecting rod 331, a long connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com