Intelligent safety risk early warning method and system for drilling engineering

A drilling engineering and safety risk technology, applied in the field of drilling engineering intelligent safety risk early warning methods and systems, can solve problems such as algorithm defects, poor model applicability, and insufficient model applicability, so as to reduce the accident rate, improve work efficiency, and achieve unattended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

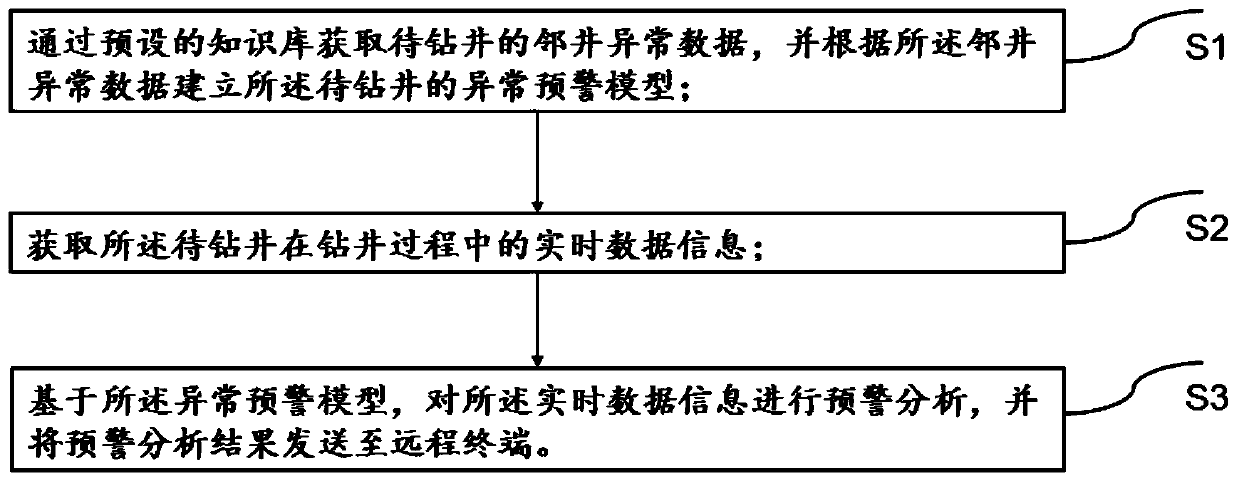

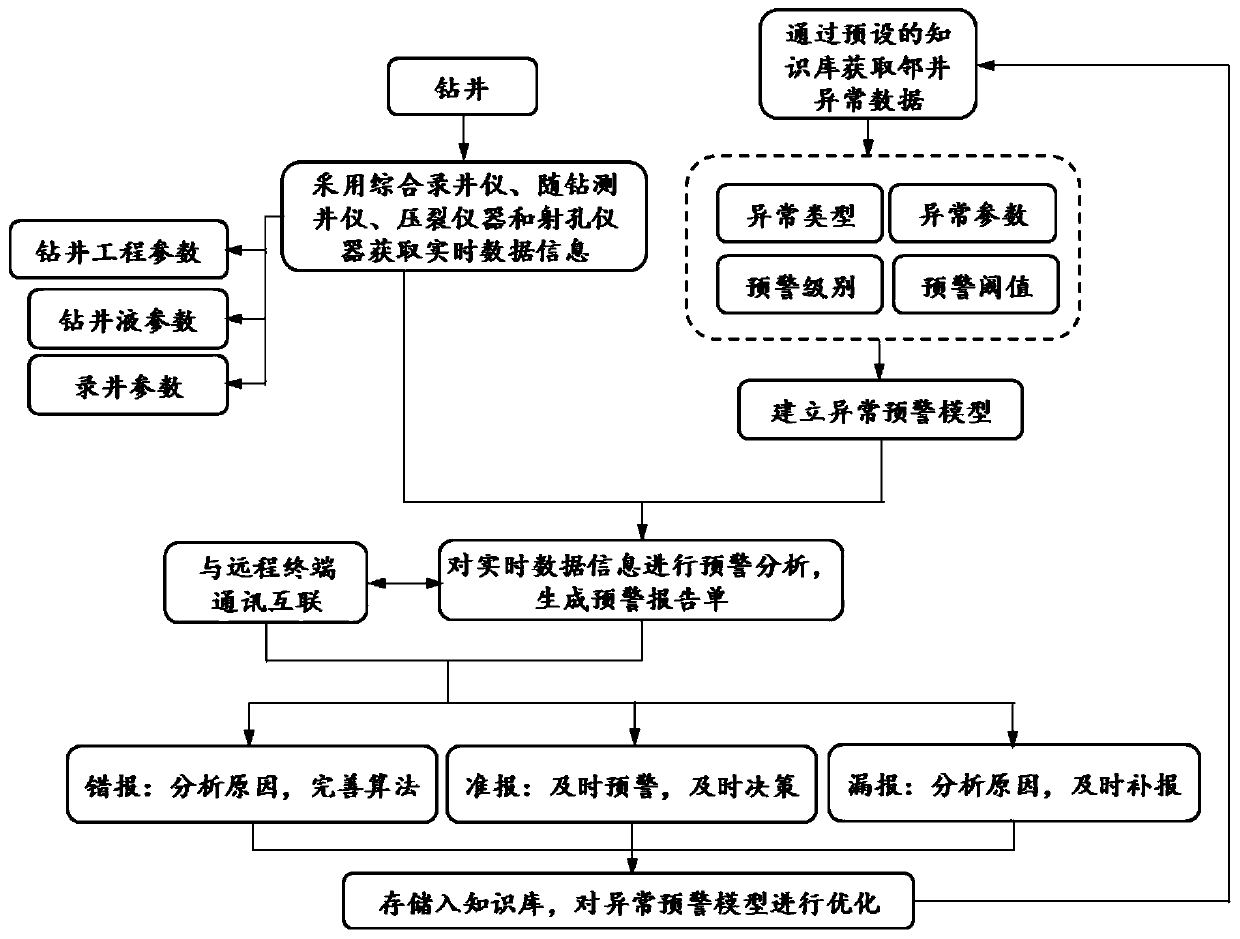

[0061] Embodiment one, as Figure 1-6 As shown, a drilling engineering intelligent safety risk early warning method includes the following steps:

[0062] S1: Obtain the abnormal data of the adjacent wells to be drilled through the preset knowledge base, and establish the abnormal early warning model of the adjacent wells according to the abnormal data of the adjacent wells;

[0063] Step 2: Obtain real-time data information of the well to be drilled during the drilling process;

[0064] Step 3: Based on the abnormal early warning model, perform early warning analysis on the real-time data information, and send the early warning analysis results to the remote terminal.

[0065] Based on the search of the preset knowledge base, the abnormal data of adjacent wells can be obtained, which provides data support for the establishment of the abnormal early warning model of the well to be drilled, and facilitates the early warning analysis of the real-time data information during the...

Embodiment 2

[0134] Embodiment two, such as Figure 7 As shown, an intelligent safety risk early warning system for drilling engineering, including a search module, an abnormal early warning model establishment module, an acquisition module and a processing module;

[0135] The search module is used to obtain abnormal data of adjacent wells to be drilled through a preset knowledge base;

[0136] The abnormal early warning model establishment module is used to establish the abnormal early warning model of the well to be drilled according to the abnormal data of the adjacent well;

[0137] The collection module is used to obtain real-time data information of the well to be drilled during the drilling process;

[0138] The processing module is configured to perform early warning analysis on the real-time data information based on the abnormal early warning model, and send the early warning analysis results to the remote terminal.

[0139] Based on the search module, the abnormal data of adj...

Embodiment 3

[0149] Embodiment 3. Based on Embodiment 1 and Embodiment 2, this embodiment provides another intelligent safety risk early warning system for drilling engineering, including a processor, a memory, and a program stored in the memory and operable on the processor. A computer program, the specific steps of S1-S3 in Embodiment 1 are implemented when the computer program runs.

[0150] Through the computer program stored in the memory and run on the processor, the intelligent safety risk warning system for drilling engineering of the present invention is realized, which facilitates real-time monitoring of the drilling work at the well site, and when an abnormality occurs, relevant personnel can be notified in time to adopt corresponding decisions. It has achieved timely tracking, forecasting and early warning, which can effectively avoid well site risks, reduce the incidence of accidents, realize efficient drilling, intelligent decision-making, unattended well site, higher intellig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com