Piezoelectric type variable stiffness and variable damping dynamic vibration absorber

A technology of dynamic shock absorber and variable stiffness, which is applied in the direction of shock absorber, elastic shock absorber, friction shock absorber, etc., which can solve the problems of non-adjustable natural frequency, complex structure, mechanical wear, etc., and achieve good vibration reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

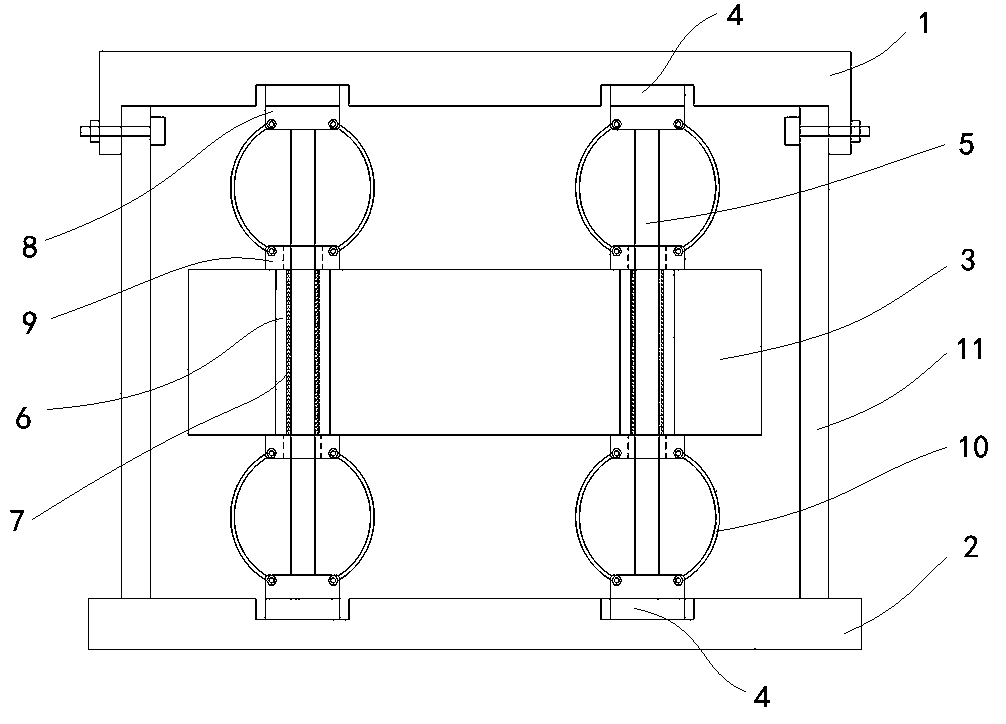

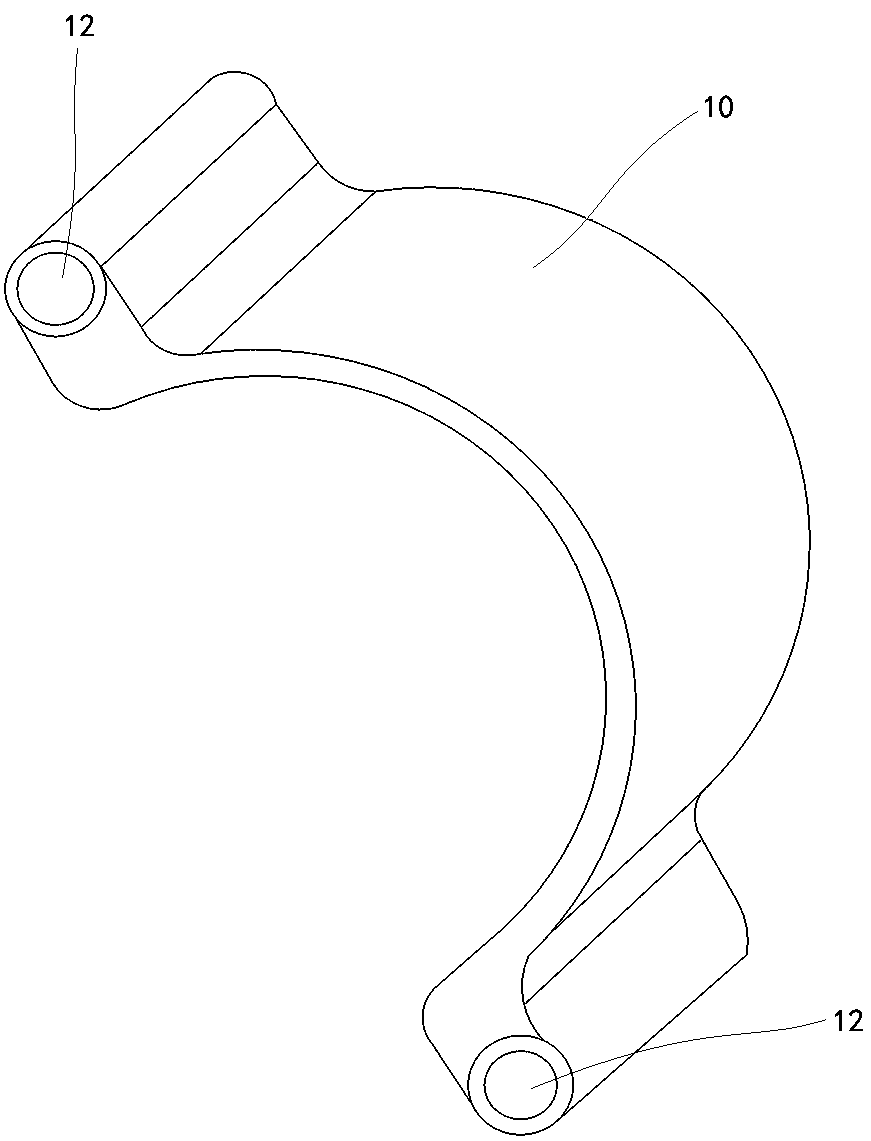

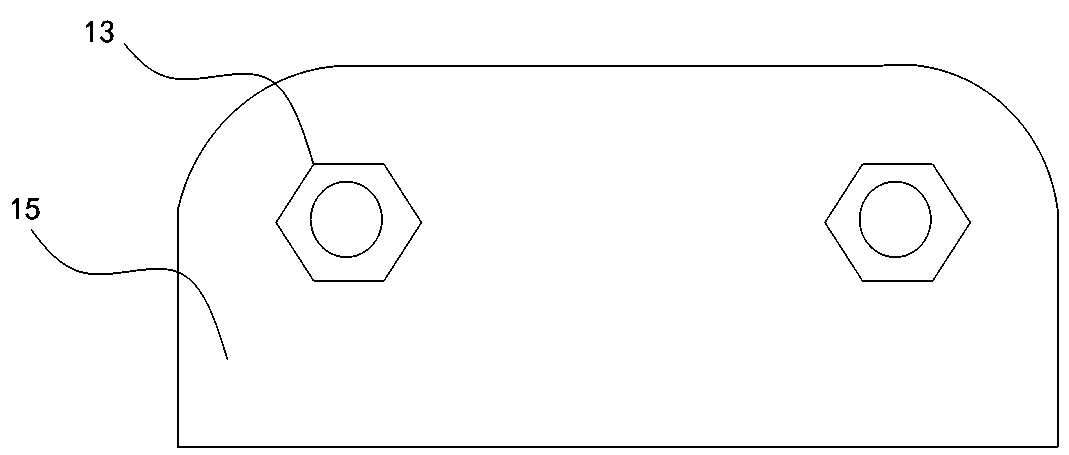

[0024] Example: such as Figure 1-6 As shown, this embodiment specifically relates to a piezoelectric variable-stiffness variable-damping dynamic vibration absorber. By setting the vibration-absorbing unit and the first piezoelectric element 4 and the second piezoelectric element 6 therein, artificial control of the dynamic vibration absorber can be realized. Stiffness and damping coefficients.

[0025] Such as figure 1 As shown, the dynamic vibration absorber in this embodiment includes an upper platform 1, a lower platform 2, and a middle platform 11, and a mass inertia block 3 and two vibration-absorbing units are arranged between the upper platform 1 and the lower platform 2, The lower bearing platform 2 is fixedly connected with the equipment to be damped, the top of the middle bearing plate 11 is fixedly connected with the upper bearing platform 1 , and the bottom of the middle bearing plate 11 abuts on the lower bearing platform 2 . The overall frame of the dynamic vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com