Intelligent constant-filling hydraulic coupling

A hydraulic coupling, intelligent technology, applied in the direction of instruments, measuring force, fluid transmission devices, etc., can solve the problems of difficult quality assurance, reduction of overload capacity of working machines, removal of hydraulic coupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

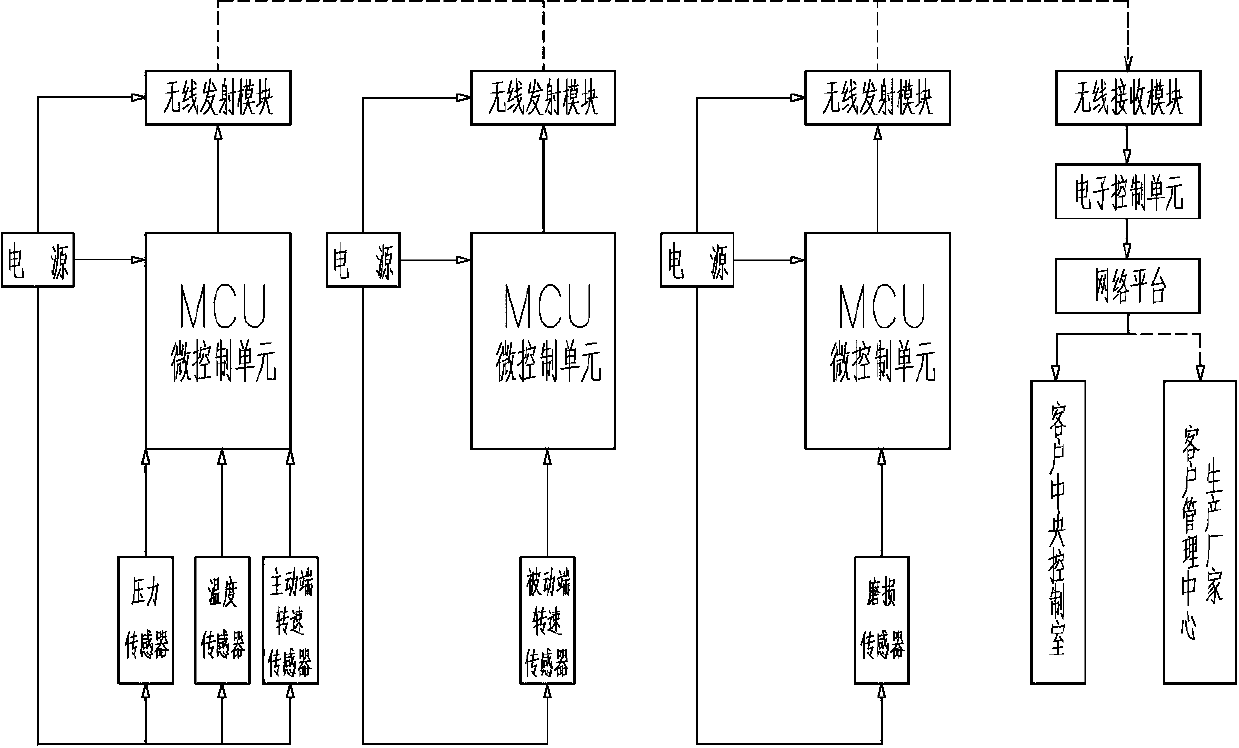

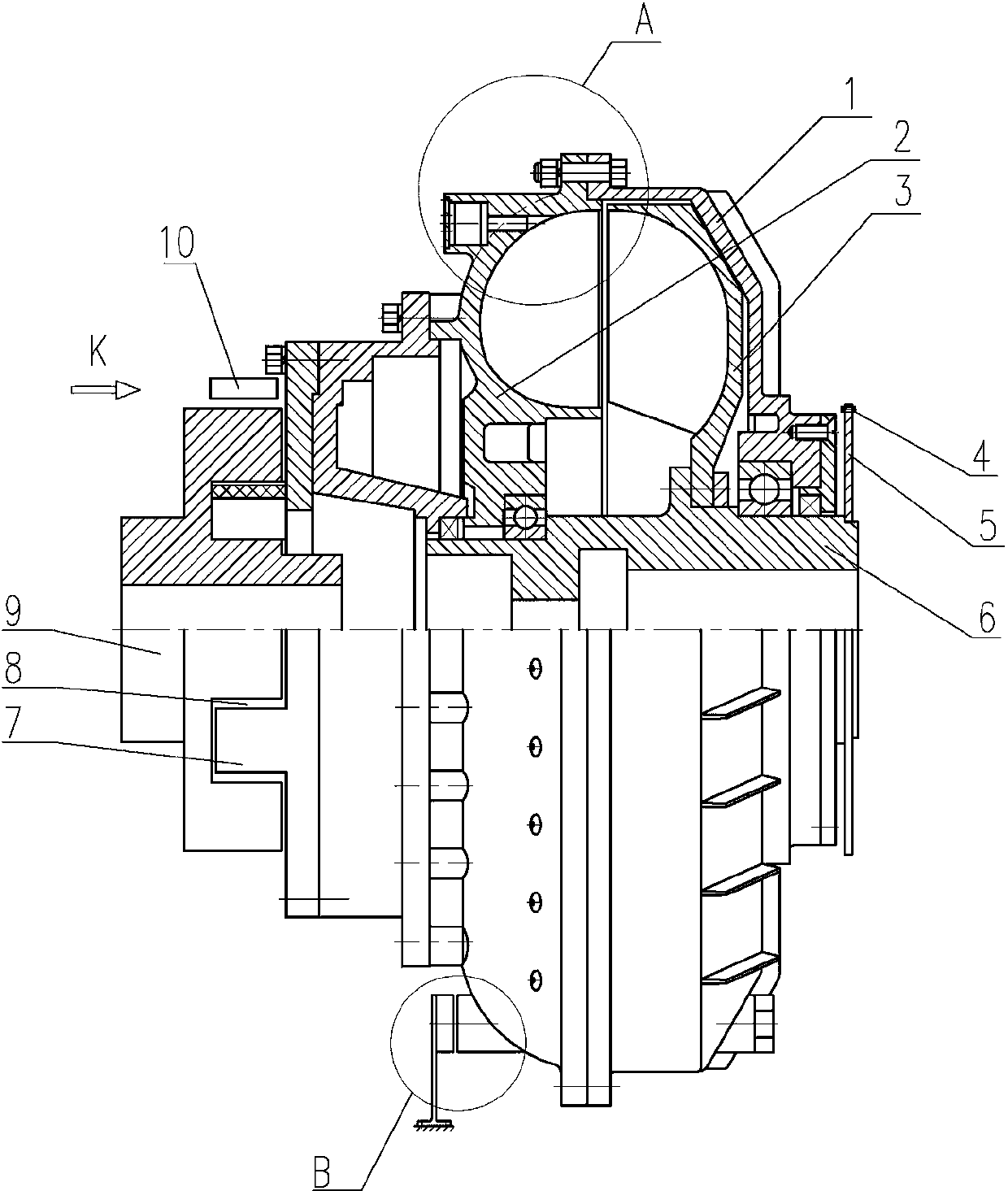

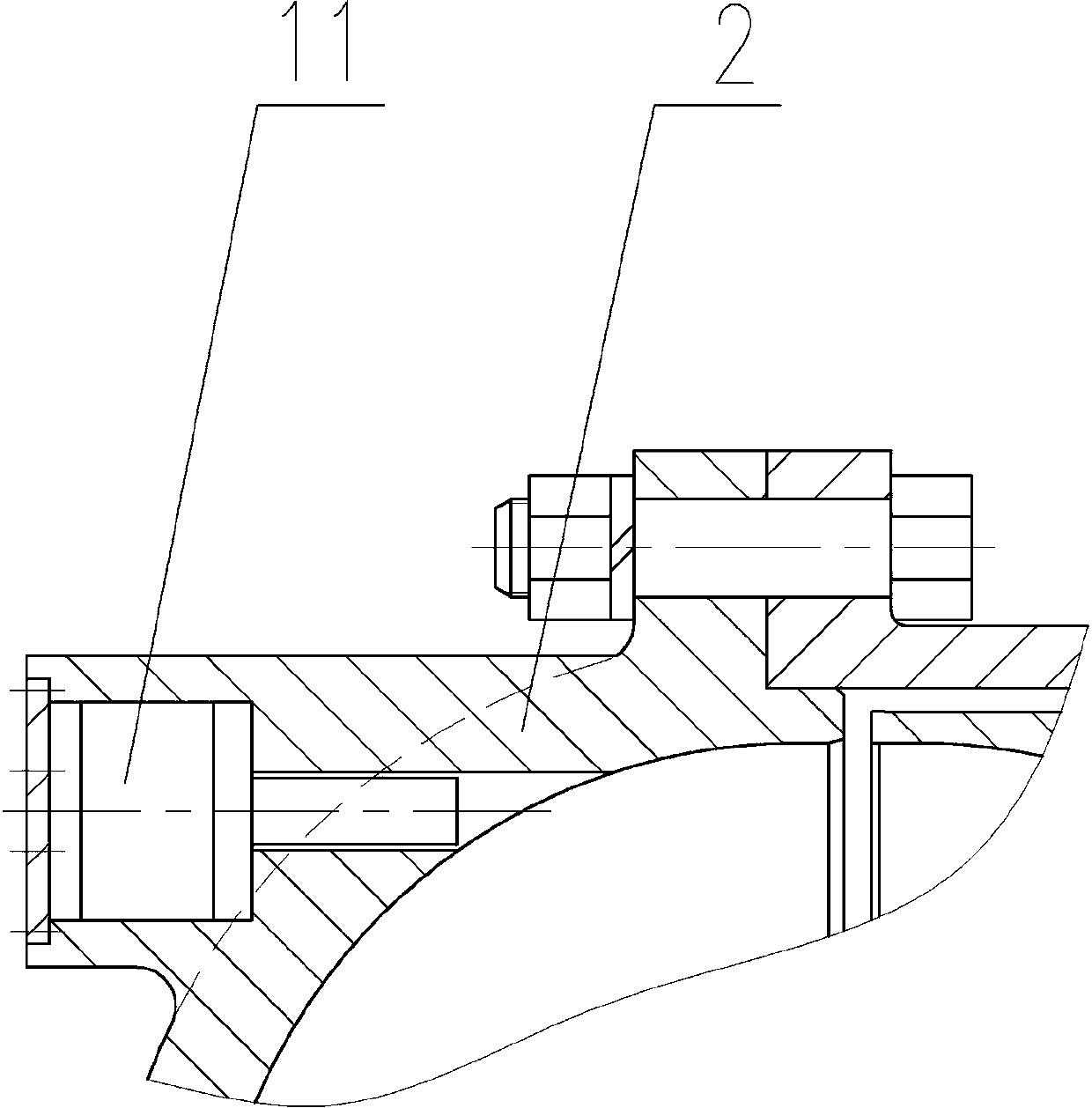

[0031] Depend on figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 It can be seen that an intelligent fixed-fill hydraulic coupling includes a casing 1, a pump wheel 2, a turbine 3 installed on the main shaft 6, and an elastic coupling connected to the pump wheel 2. On the casing 1 or the pump wheel 2 A pressure sensor for detecting the pressure in the working chamber of the hydraulic coupling, a temperature sensor for detecting the temperature of the working medium, and an active-end speed sensor for detecting the speed of the pump wheel are provided, and a passive-side speed sensor for detecting the speed of the turbine 3 is installed on the main shaft 6; The sensor signals at the active end of the force coupling and the sensor signals at the passive end of the hydraulic coupling are collected and sent to their respective MCU micro-control units for processing, and then transmitted through the wireless transmitting module, and then transmitted to the electronic cont...

Embodiment 2

[0056] Depend on Figure 4 , Figure 6 It can be seen that the wear sensor 10 of this embodiment and the corresponding power supply, MCU micro control unit, and wireless transmission module are installed on the active joint 9, and the driven claw 17 of the driven joint 7 is provided with an induction head 16 corresponding to the wear sensor 10 . When the elastic block 8 is worn out, the driven joint 7 deflects, so that the induction head 16 on the driven claw 17 corresponds to the wear sensor 10, thereby sending out a wear signal of the elastic block, which is transmitted through the corresponding MCU micro control unit and the wireless transmission module. After being received by the wireless receiving module, it is sent to the electronic control unit, and the electronic control unit gives an alarm to remind the customer to replace the elastic block 8 .

[0057] The power supply of this embodiment adopts a power generation mechanism installed on the hydraulic coupling, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com