A method for calculating the time-varying meshing stiffness of an internal meshing gear pair of a straight-tooth cylindrical gear

A technology of spur gears and time-varying meshing stiffness, which is applied in calculation, instrumentation, electrical digital data processing, etc., and can solve problems such as complex modeling process, time-consuming, and insufficient accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In order to explain the present invention more clearly, the following embodiments are described in detail in conjunction with the accompanying drawings.

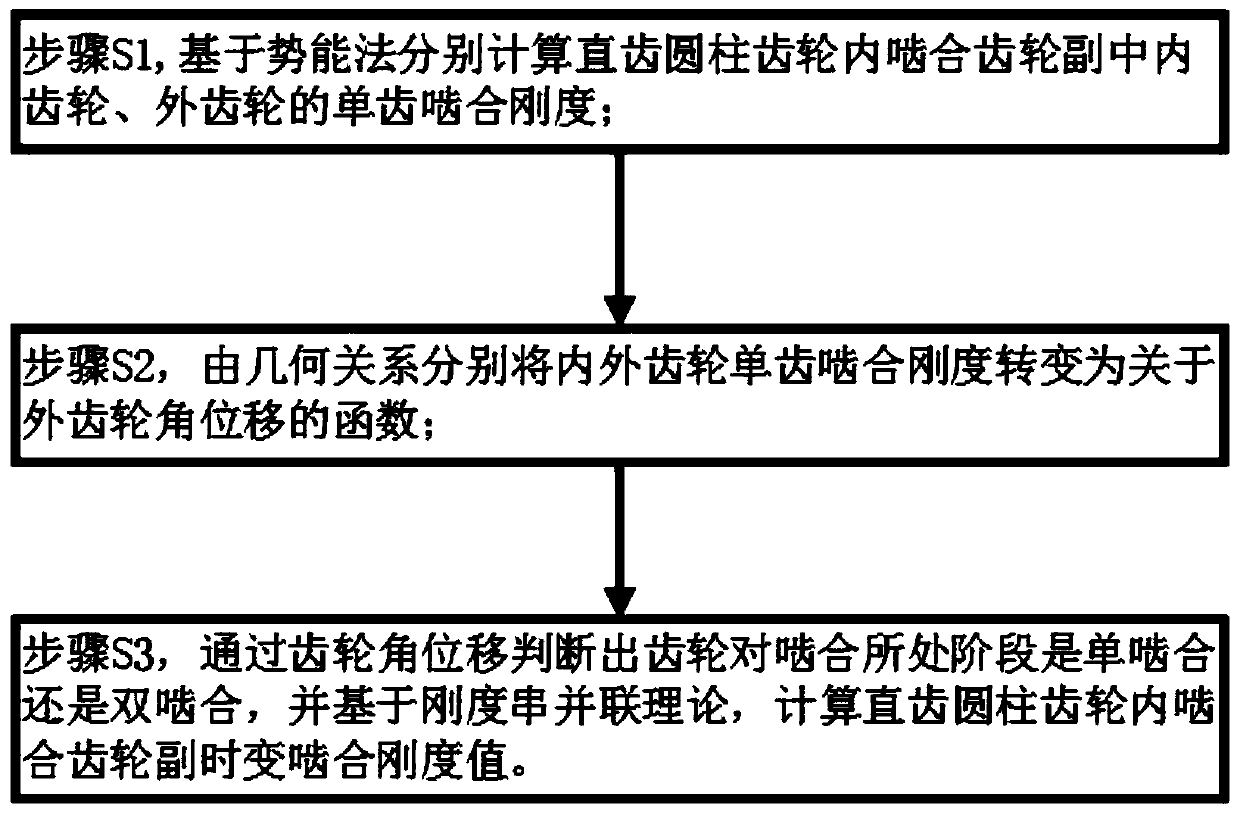

[0091] figure 1 It is a flowchart of a method for calculating the time-varying meshing stiffness of a spur gear internal meshing gear pair disclosed in the present invention, combining figure 1 , the steps of the specific embodiment of the present invention are:

[0092] Step S1, calculating the meshing stiffness of a single tooth of the internal and external gears in the spur gear internal meshing gear pair, specifically including:

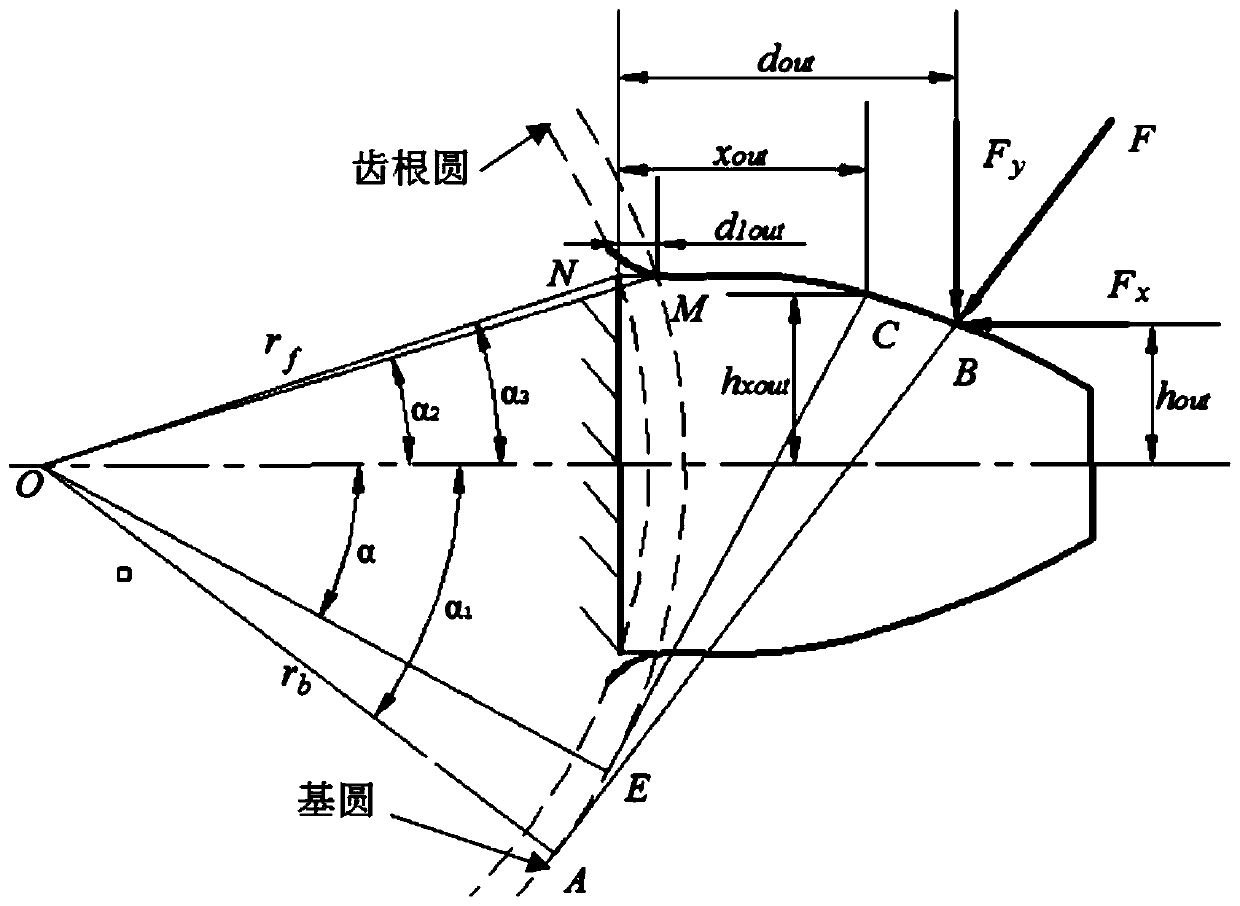

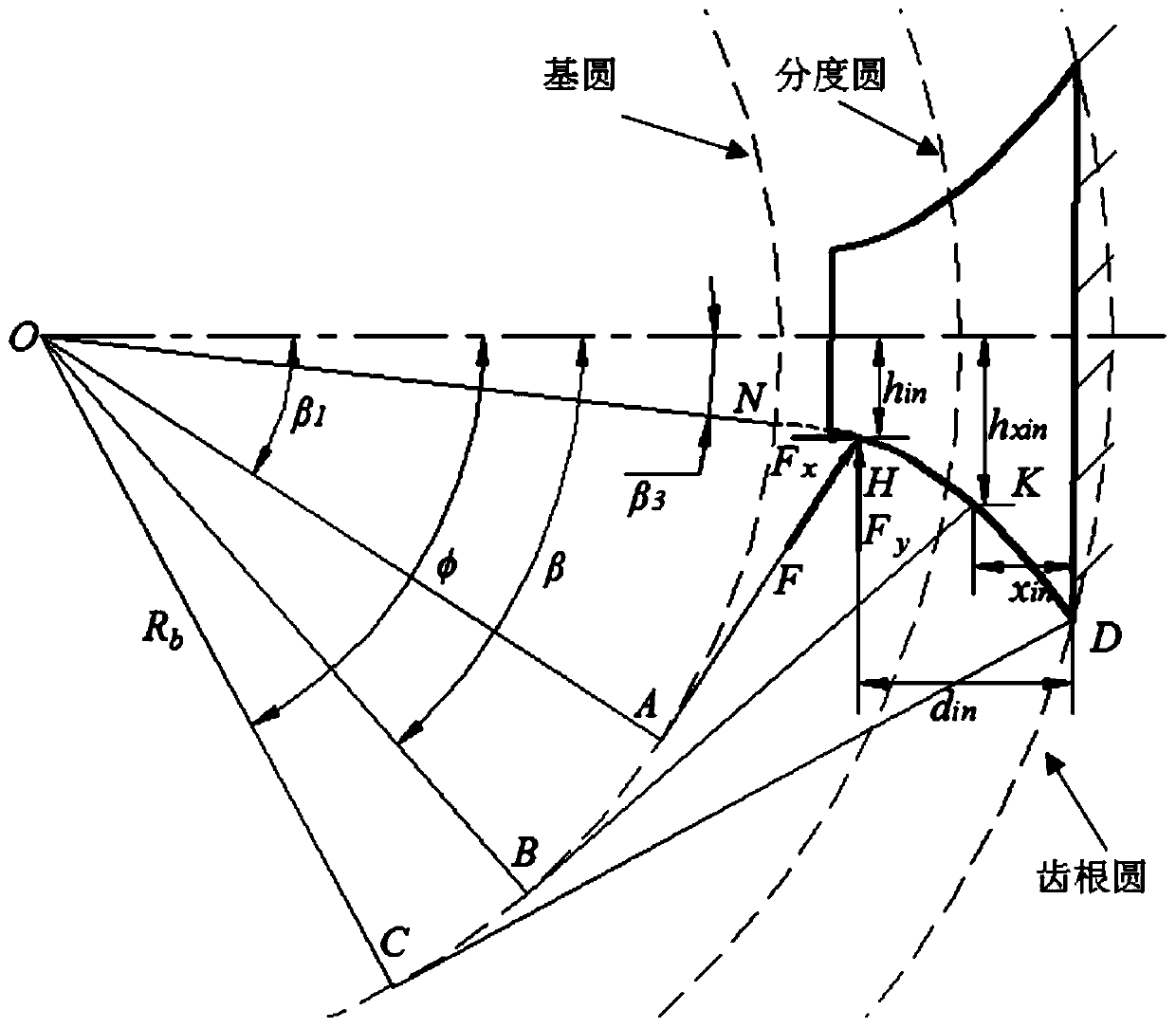

[0093] In step S11, the teeth of the internal and external gears are equivalent to a cantilever beam, and the contour shape of the cantilever beam is judged based on the relationship between the addendum circle and base circle diameter of the internal gear, and the dedendum circle and base circle diameter of the external gear;

[0094] When the gear teeth mesh, the deformation of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com