Hanging bar direct current brushless fan motor

A DC brushless and fan technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of complex control process, limited application occasions, high voltage, etc., to avoid displacement or falling off, improve safety, and reduce load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

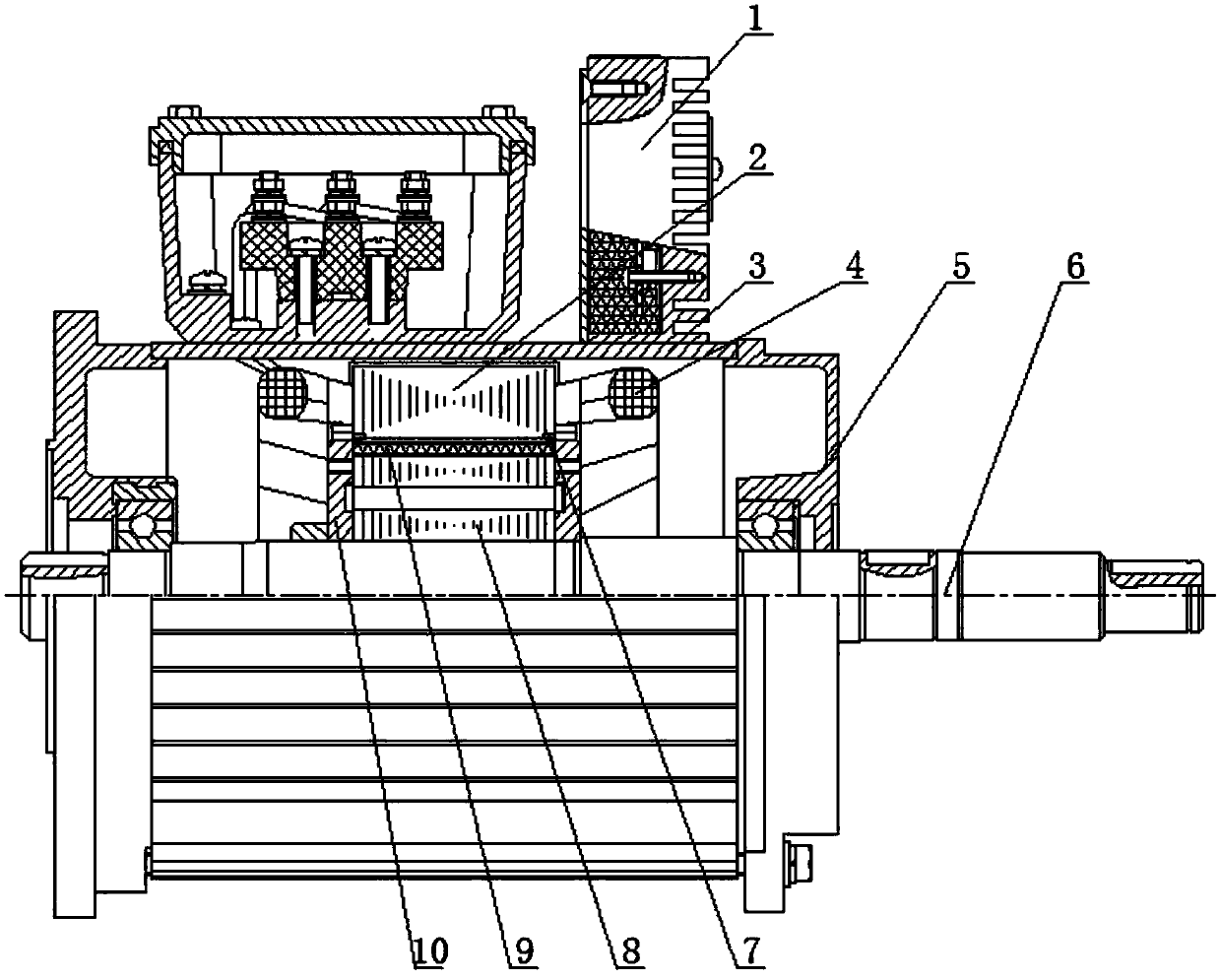

[0014] A suspension rail DC brushless fan motor, including a casing 3, an end cover 5 is installed on both sides of the casing, and a motor shaft 6 is installed in rotation between the two ends of the cover, and the outer side of the motor shaft is installed There is a rotor 8, a stator 2 is installed in the outer casing of the rotor, and a plurality of windings 4 are installed in the stator. The innovation of the present invention is that a plurality of magnetic steels 9 are installed at even intervals on the outer side of the rotor, and each A position sensor 7 is respectively installed in the stator relative to the position of the magnet, and the position sensor is used to detect the corresponding signal of the position of the magnet. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap