Reactor for treating polystyrene material

A polystyrene and reactor technology, applied in plastic recycling, recycling technology, chemical instruments and methods, etc., can solve the problems of different consistency, sensitive to the quality and quantity of polystyrene feed, and low conversion process efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Methods of processing polystyrene material (eg, waste polystyrene material) within the reactors of the system are described below. Suitable waste polystyrene materials include, but are not limited to, expanded and / or extruded polystyrene foam and / or rigid products. Virgin polystyrene can also be used.

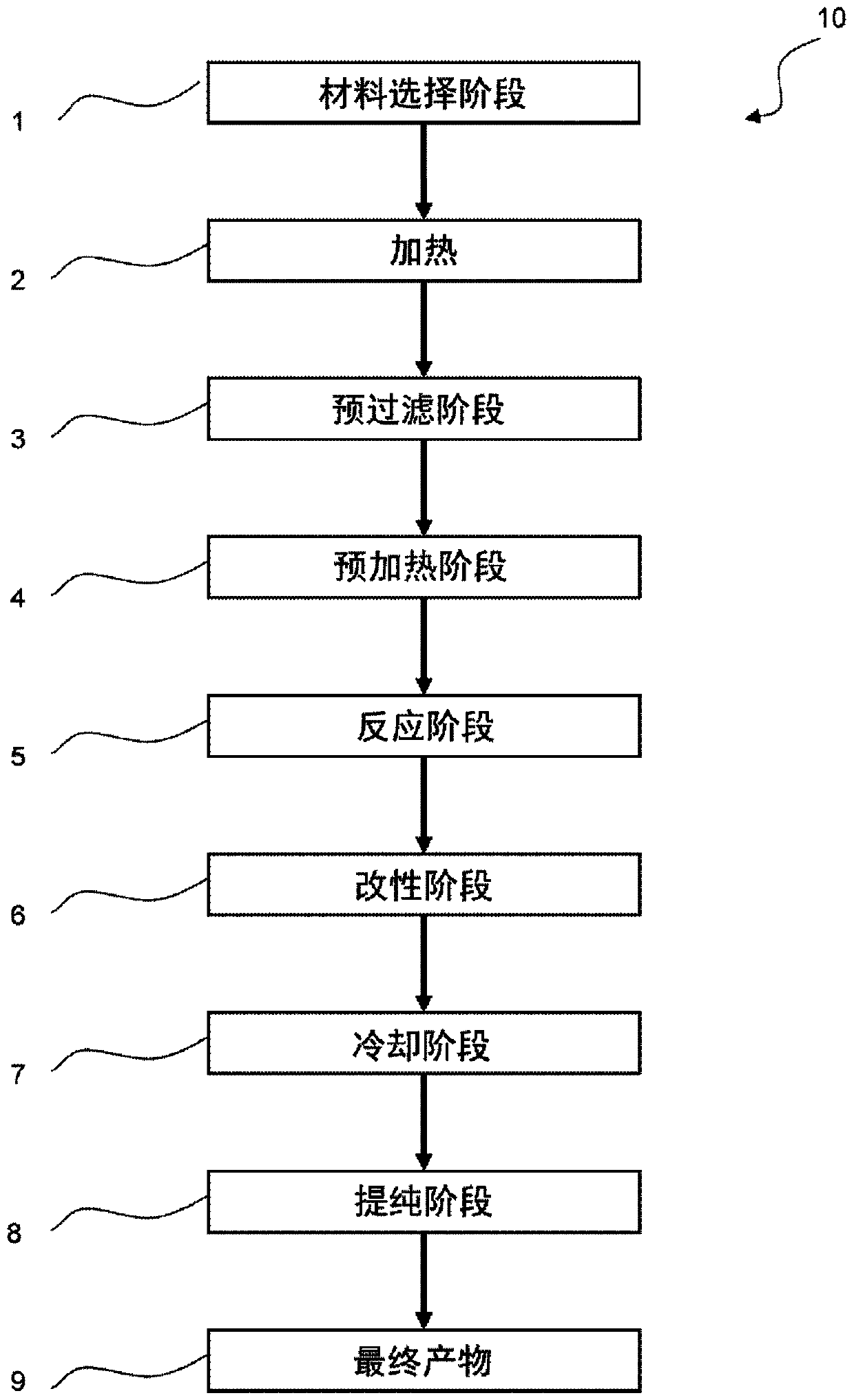

[0061] Figure 1A A method 10 for processing polystyrene material is illustrated. Process 10 can be performed batchwise, but is more preferably a continuous process. The parameters of method 10 (including but not limited to temperature, flow rate of polystyrene, grafted monomer / copolymer during the reaction and / or modification stages, and the total number of preheating, reaction, or cooling stages) can be modified to produce End products of different molecular weights, such as macromers or PAH products. For example, increasing the temperature and / or decreasing the flow rate through the reaction section or changing the number of reaction sections will result in a produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com