Gate valve structure and production method therefor

A manufacturing method and gate valve technology, applied in the valve shell structure, manufacturing tool, sliding valve and other directions, can solve the problems of raw material waste and cost increase, and achieve the effect of shortening the construction period, reducing the cost of repairing, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

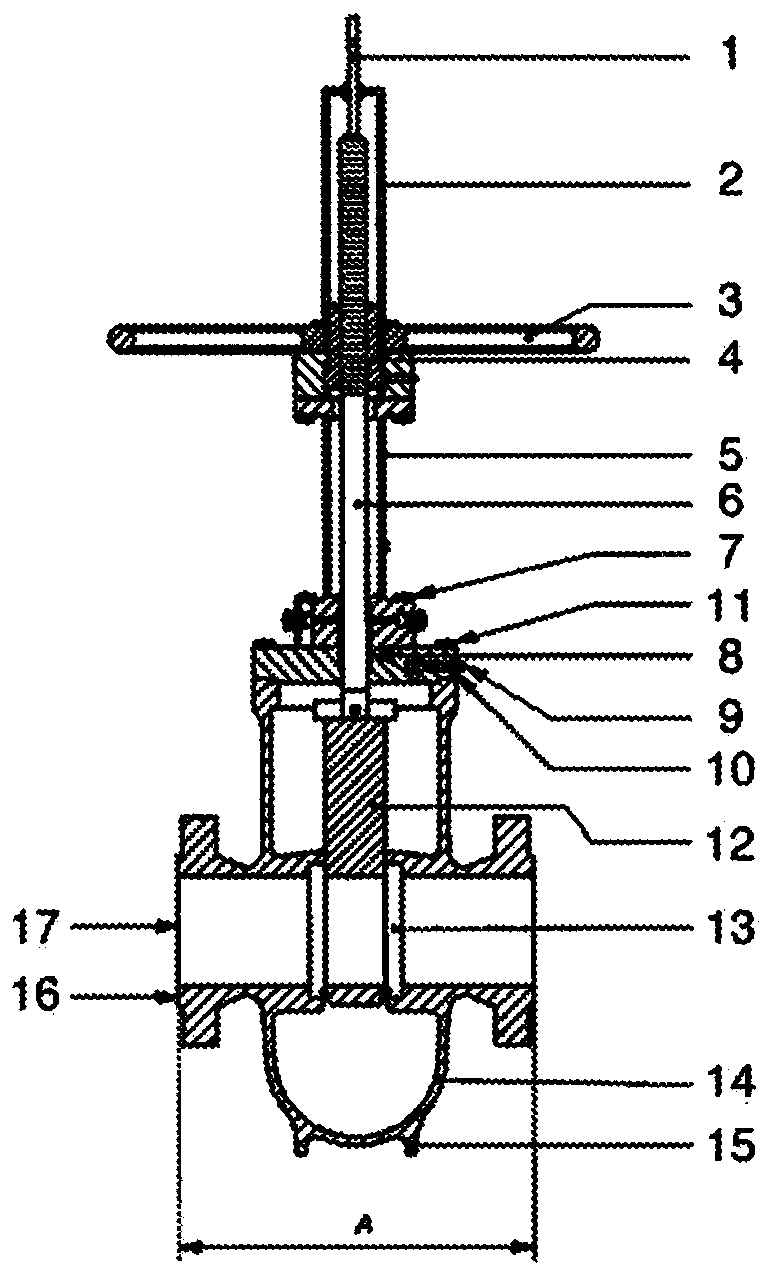

[0042] When the valve body is produced by forging, if it has an axisymmetric shape, it can be easily produced by ring forging or die forging. However, both ring forging and die forging are difficult to form a product with a large length / diameter ratio or a product with a thin wall thickness. In order to facilitate forging, such as Figure 4A As shown, the valve body is divided at the connecting pipe portion so that the length / diameter ratio becomes small. In addition, by dividing the bulging portion that can die-forge the central portion of the valve body, a material close to the final shape can be used, thereby reducing material costs.

[0043] Use iron and steel materials with a carbon content of 0.1-0.4%, hot forge the parts 40 and 41 of the valve body at 1000-1500°C, and perform heat treatment (quenching, annealing) if necessary. in such as Figure 4B After the hemispherical valve body parts 40, 41 are welded in this way, the opening 42 ( Figure 4C ). For example, a ...

Embodiment 2

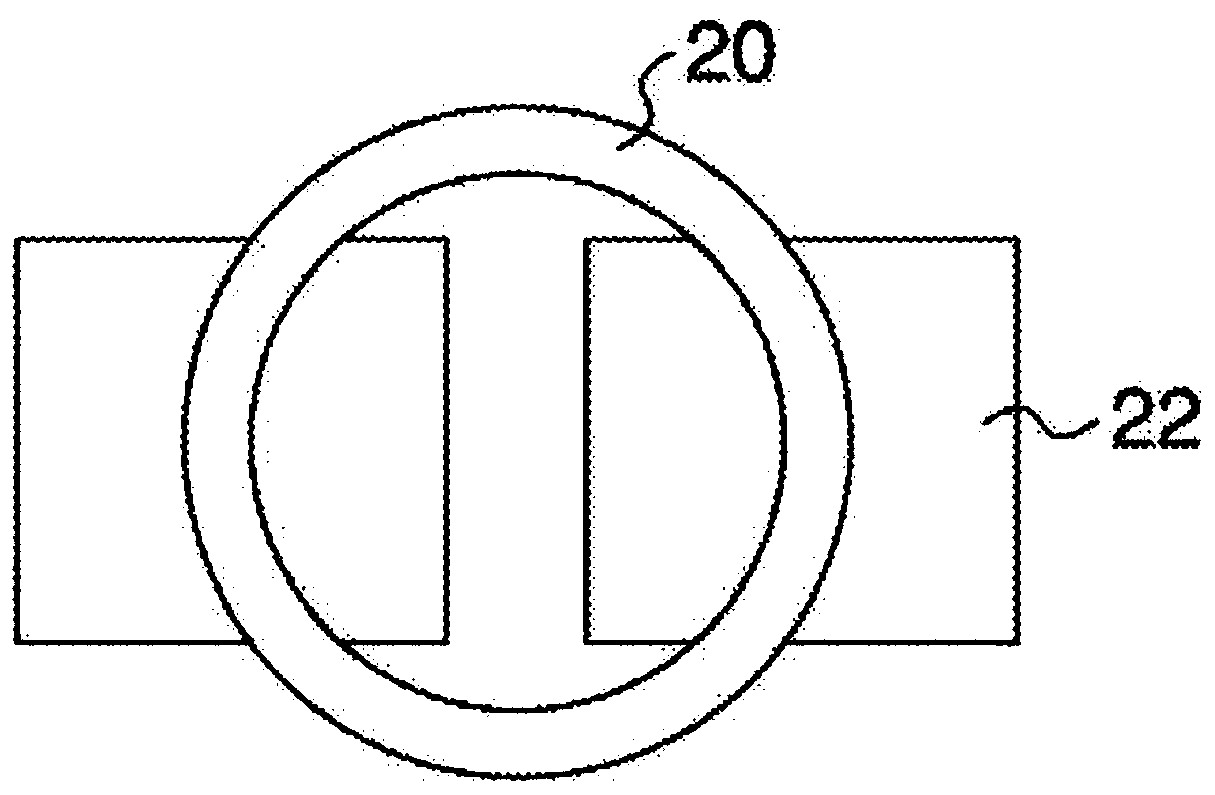

[0048] In the present invention, the welded portion of the connecting pipe may also be formed as Figure 5 structure shown. That is, on the outside of the connecting pipe 55, an annular protruding portion 57 is integrally formed with the connecting pipe in the form of a part of the spherical portion of the valve body, and the outer periphery of the protruding portion 57 is made with it. The boundaries between matching openings serve as welds 53 . If the protruding portion 57 protrudes more than 2 cm outside the connecting tube, the radiation 61 from the radiation source 60 can be easily irradiated to the welded part 53 in the radiation inspection, and the photosensitive film 62 for radiation detection can be easily placed on the surface of the joint. Since it is fixed inside the valve body, radiological inspection can be easily performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com