Five-axis linkage round hole glue dispenser

A five-axis linkage and glue dispenser technology, which is applied to coatings, devices that apply liquid to the surface, etc., can solve the problems that the dispensing platform cannot meet the needs of full-screen dispensing, and the round holes cannot be opened too large. , to achieve the effect of simple structure, simple control and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

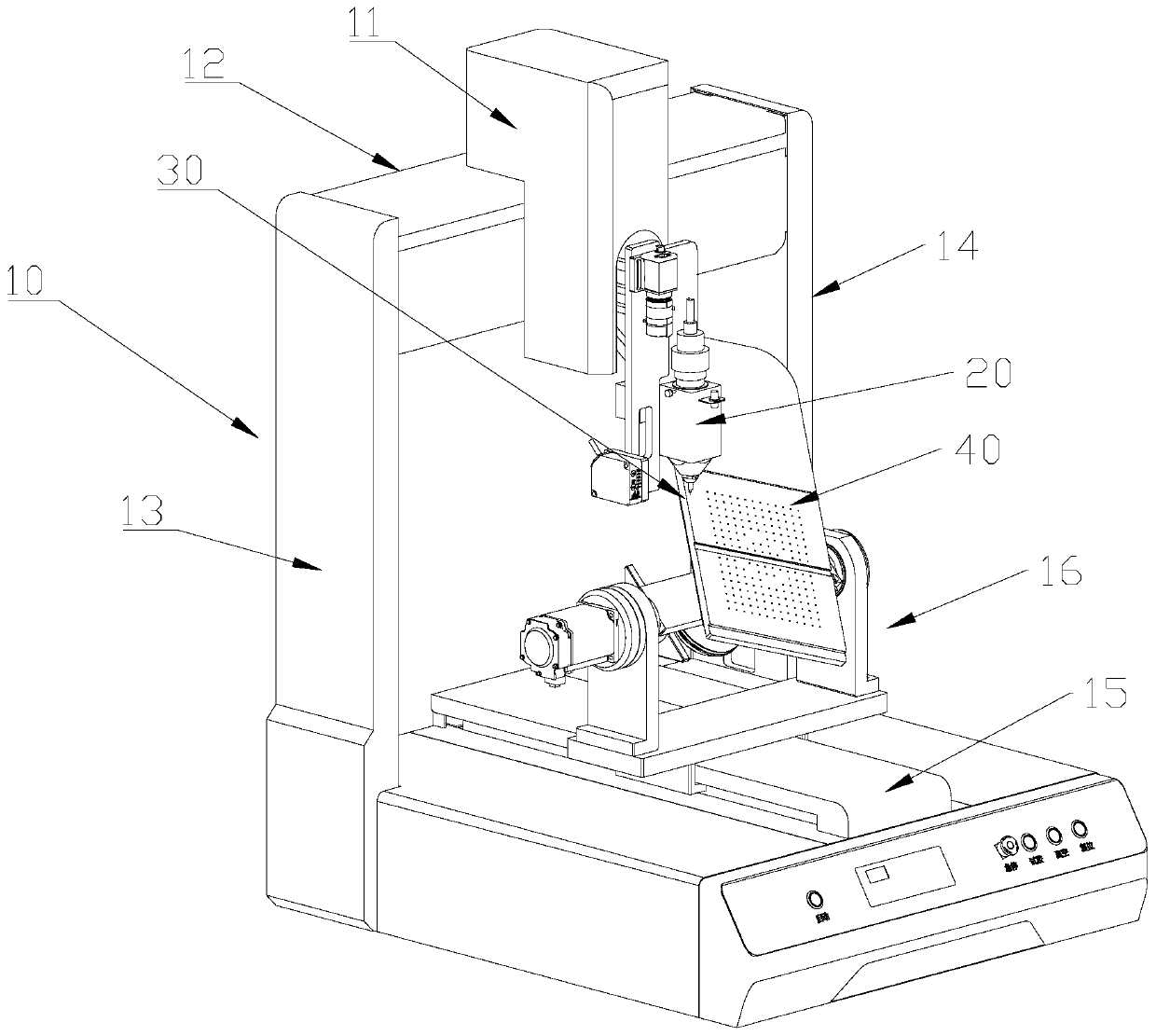

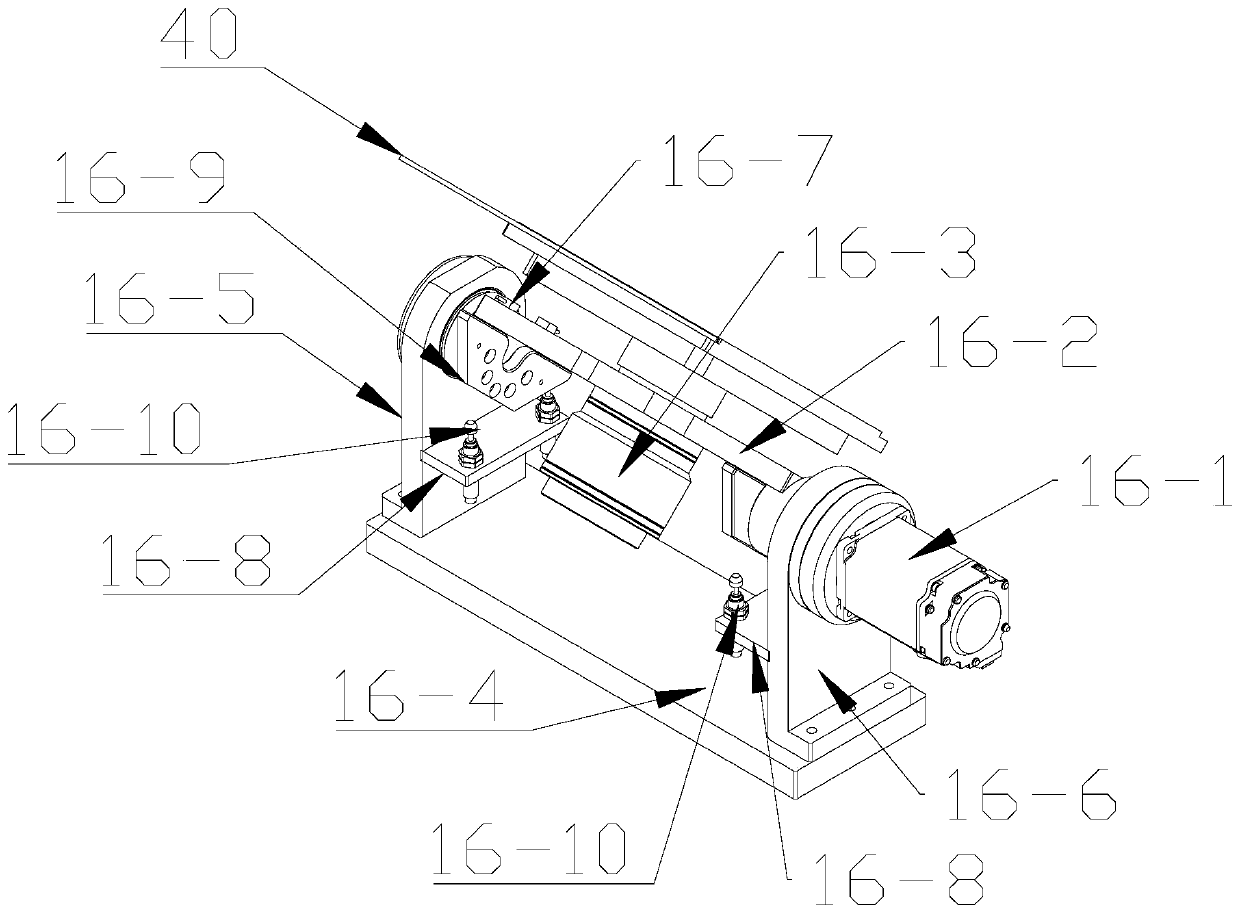

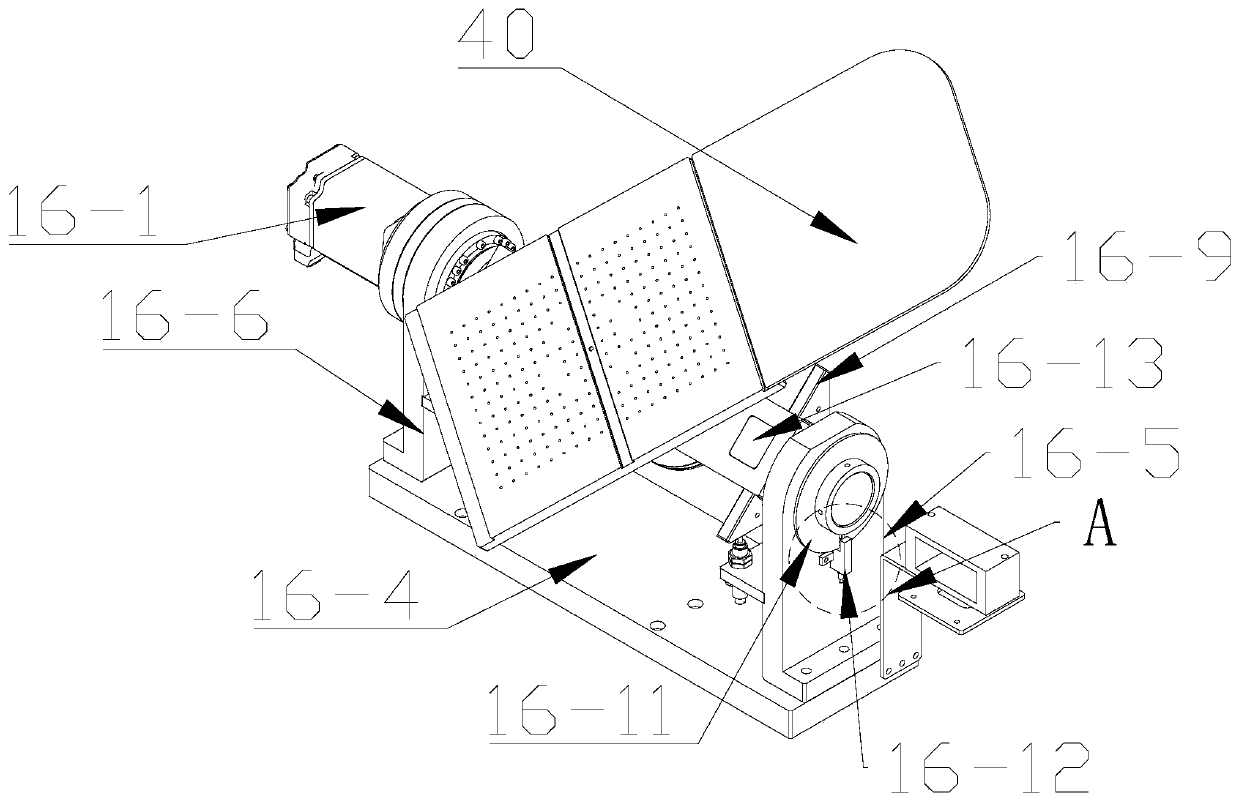

[0025] like figure 1As shown, the five-axis linkage circular hole dispenser of the present invention includes a frame 10, a dispensing head assembly 20, a porous adsorption platform 40 and a calibration system 30 for spatial calibration. The frame 10 includes a left vertical plate 13, Right vertical plate 14, the first linear guide rail slide table 11, the second linear guide rail slide table 12, the third linear guide rail slide table 15 and the biaxial rotating mechanism 16, the described biaxial rotating mechanism 16 includes a base, a servo Motor 16-1, rotating bracket 16-2 and hollow rotating DD motor 16-3; the calibration system 30 is installed on the dispensing head assembly 20, and the dispensing head assembly 20 is installed on the first straight line on the slide block of the guide rail slide table 11 and move freely along the guide rail of the first linear guide rail slide table 11, and the first linear guide rail slide table 11 is installed on the slide block of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com