Fixing device for three-roll skew rolling mill

A technology of fixing device and skew rolling mill, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of inability to guarantee the stability and consistency of product production, waste of time and manpower, and the impact of pipe body Part of the quality of the processing and other issues, to enhance the practicality, reduce manpower operations, the operation process is simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

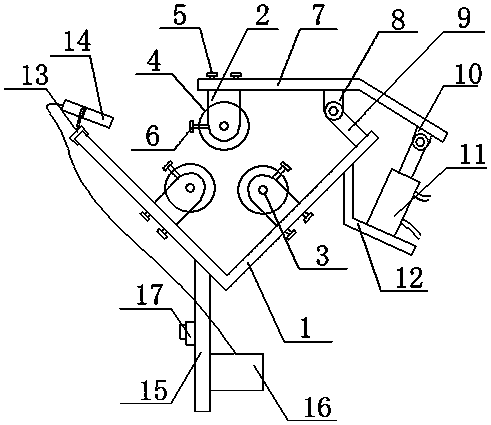

[0015] Combine below figure 1 The fixing device of a three-high cross rolling mill of the present invention is further described.

[0016] A fixing device for a three-roll skew rolling mill, which is characterized in that it comprises a base 1, a drum 4, and a rotating arm 7. The base 1 adopts angle iron, and a fixing seat is provided on both sides of the base 1 and the front end of the rotating arm 7. 2. A round hole 3 is provided on the fixing base 1-2, a roller 4 is connected to the round hole 3, a fixing clip 13 is arranged on the left edge of the base 1, and an induction head is arranged on the fixing clip 13 14. The right side edge of the base 1 is provided with a support seat two 9, and the upper end of the support seat 9 is connected with a fixed seat two 8, and the fixed seat two 8 is connected in the middle of the rotating arm 7, and the rotating arm 7 tails One end is provided with a connecting seat 10, the connecting seat 10 is successively provided with an air cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com