A kind of optical glass sticking film method

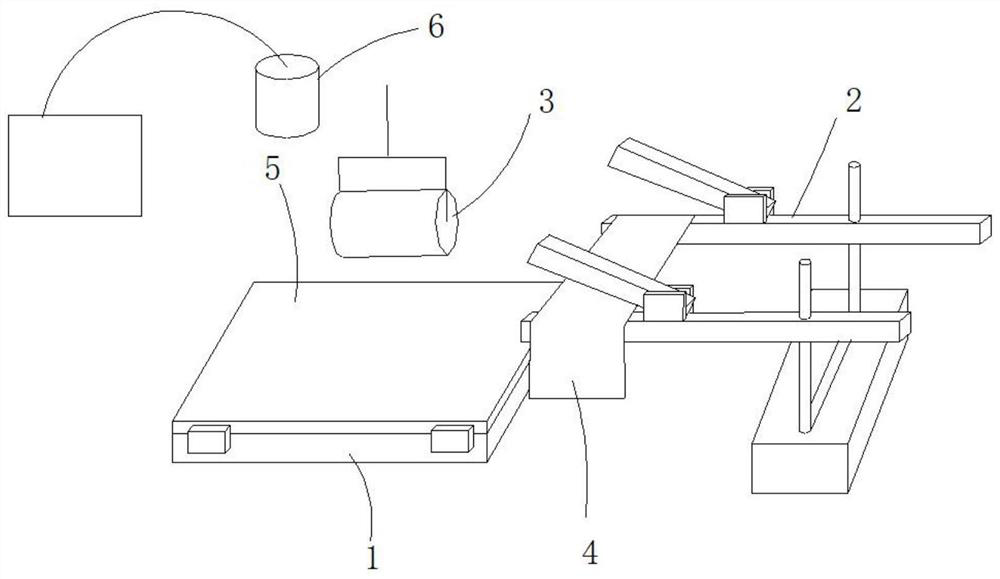

An optical glass and film technology, applied in optical components, home appliances, other home appliances, etc., can solve the problems of poor verticality of the film, eye fatigue, and the distance between the film and the film is not easy to control, etc., to achieve stable fixation and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

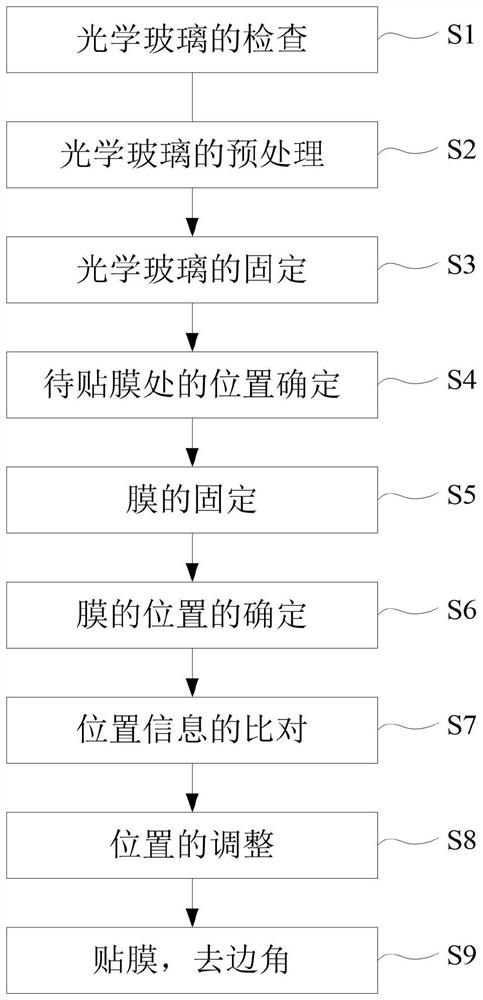

[0033] see figure 2 As shown, an optical glass laminating method applied to the above-mentioned optical glass laminating equipment, comprising:

[0034] Step S1: The staff wears silk gloves and holds the optical glass to inspect the surface of the optical glass. Before the optical glass is filmed, the surface of the optical glass to be filmed is inspected to find out the stains on the surface of the optical glass. The stain of the optical glass is judged by the method of water infiltration of the glass, cover the surface of the optical glass with clean water, the water adheres to the surface of the optical glass, and there are droplets or gaps on the formed water film, indicating that the surface of the optical glass has stains;

[0035] Step S2: Pretreatment of the optical glass, the staff wears silk gloves to hold the edge of the optical glass with stains on the surface, aligns the stained area with the air outlet of the air humidifier, and wipes the stained area with a sil...

Embodiment 2

[0044] The second embodiment deals with the case where the optical glass is partially pasted and the pasted film is attached on the basis of the pasted film,

[0045] The process of steps S1-S3 is the same as that of the first embodiment;

[0046] Step S4: the CCD alignment camera obtains the edge information of the film that has been pasted; specifically, the CCD alignment camera takes pictures and measures the four corners of the top surface of the optical glass, and determines the four corners of the top surface of the optical glass. Position information or take pictures of the boundary line between the optical glass and the pasted film, and determine the position of the boundary line by determining the position of the two intersection points between the boundary line and the edge of the optical glass;

[0047] The process of steps S5-S6 is the same as that of the first embodiment;

[0048] Step S7: Compare the edge information of the film that has been pasted on the optic...

Embodiment 3

[0051] The third embodiment deals with the case where multiple films are connected and pasted on the optical glass plate in turn. First, S1-S8 of the first embodiment is implemented, and then the process of S4-S8 of the second embodiment is repeated until the optical glass plate is pasted. Finally, the implementation is carried out. In S9 of Example 1 or Example 2, a cutter is used to cut off the film beyond the surface of the optical glass, and the optical glass is removed from the fixing table.

[0052] In the above three embodiments, in the process of steps S1-S9, the inner layer of the silk gloves worn by the staff is provided with a sweat-absorbing layer, or the inner layer of the staff wears rubber gloves and the outer layer wears silk gloves to prevent the staff from sweating. Affects the cleanliness of the gloves. During the implementation of step S5, a certain horizontal distance is maintained between the film and the optical glass, so as to avoid the impact on the ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com