Honeycomb floating plate system good in seal effect and free of main and auxiliary beam structure

A technology of sealing effect and sealing system, which is applied in the field of honeycomb floating disc system, can solve the problems of failing to meet the national standard emission requirements and poor sealing effect, and achieve the effect of good sealing, simple installation structure and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

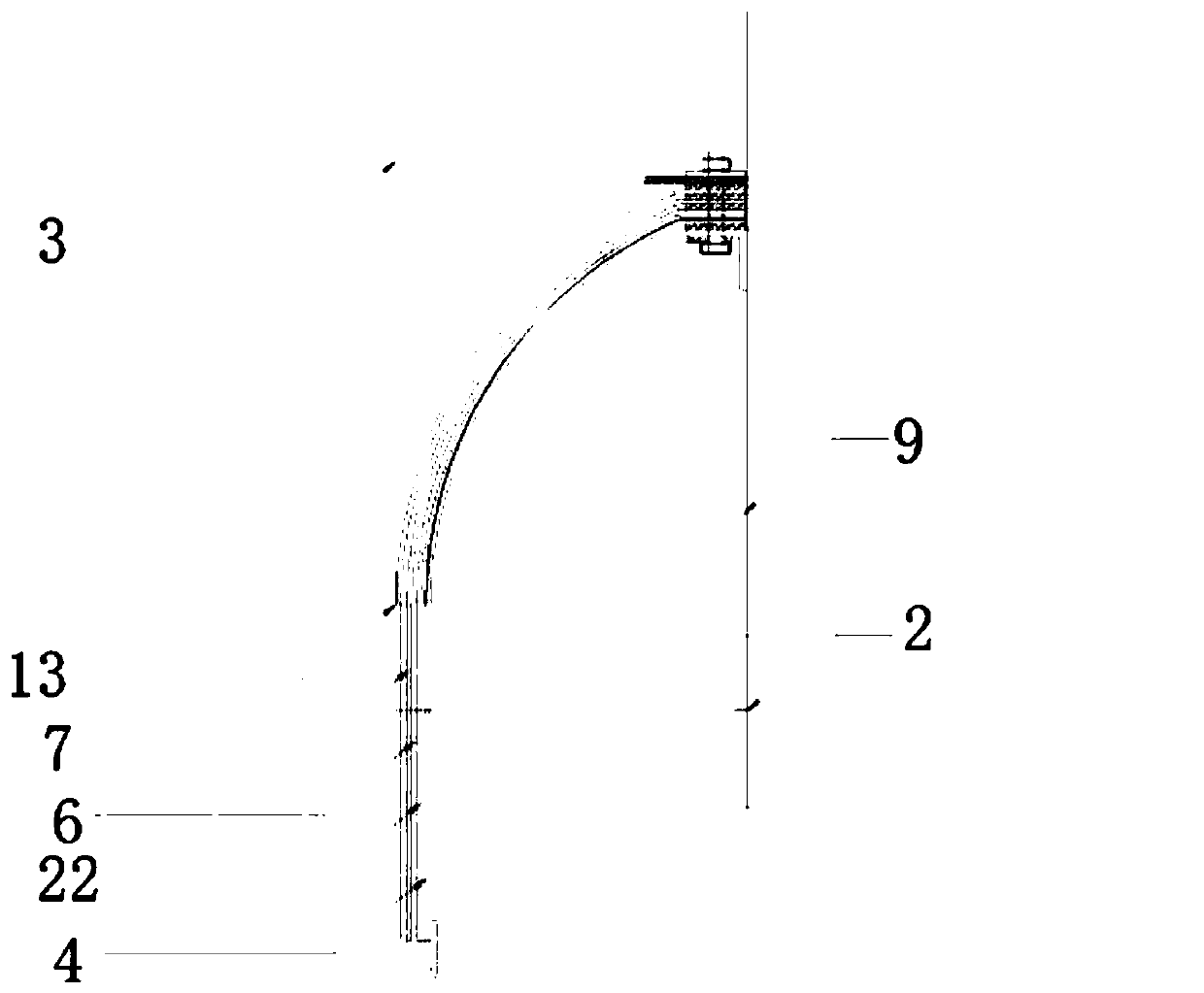

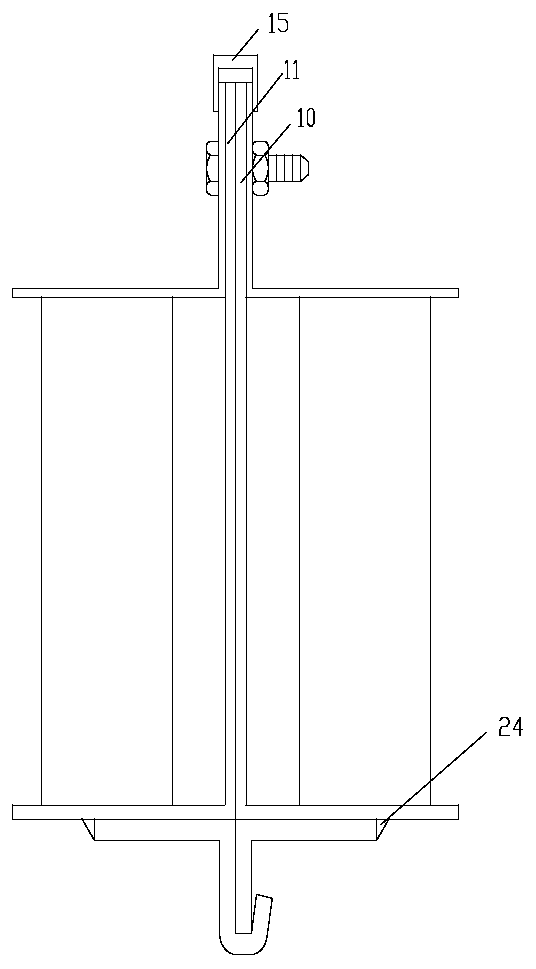

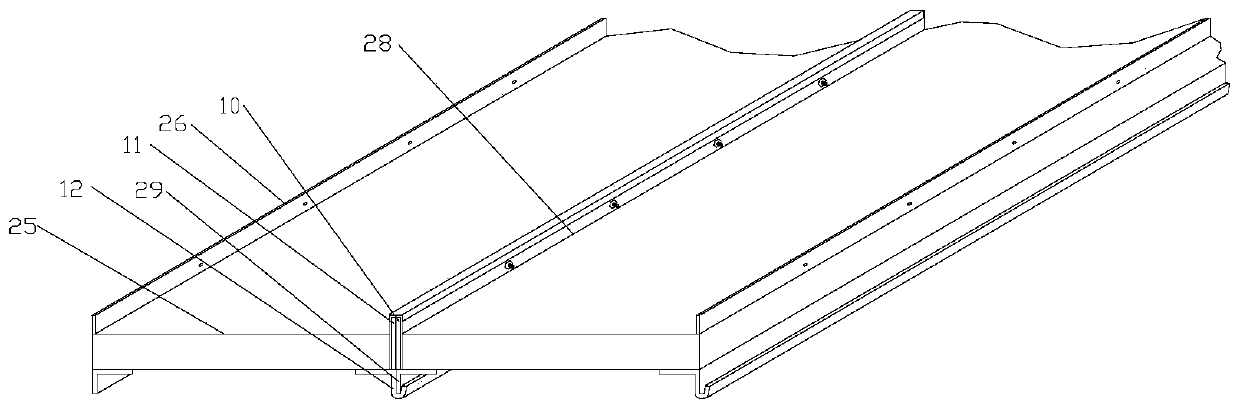

[0020] see figure 1 As shown, the honeycomb floating disc system with good sealing effect and no main and sub-beam structure includes a sealing system and several honeycomb boxes. It is characterized in that the sealing system includes an edge plate and a sealing device, and one end of the sealing device is installed on The other end is in contact with the tank wall; the sealing device includes membrane-supported stainless steel shrapnel, PTFE fiber membrane, supplementary elastic stainless steel plate, and high-elastic stainless steel shoe; the side wall of the edge plate is provided with There is a sealing protective film; the floating plate body is formed by connecting several honeycomb boxes floating on the liquid surface through hook-type plugging, and the sides of the honeycomb box body are composed of the first side, the second side, the third side and the fourth side. The sides are connected; the first side and the second side are provided with a first mounting plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com