Preparation method and apparatus of composite laser gain medium

A technology of laser gain and composite structure, applied in the field of laser applications, can solve the problems of low yield and difficult preparation, and achieve the effects of high yield, improved energy storage capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

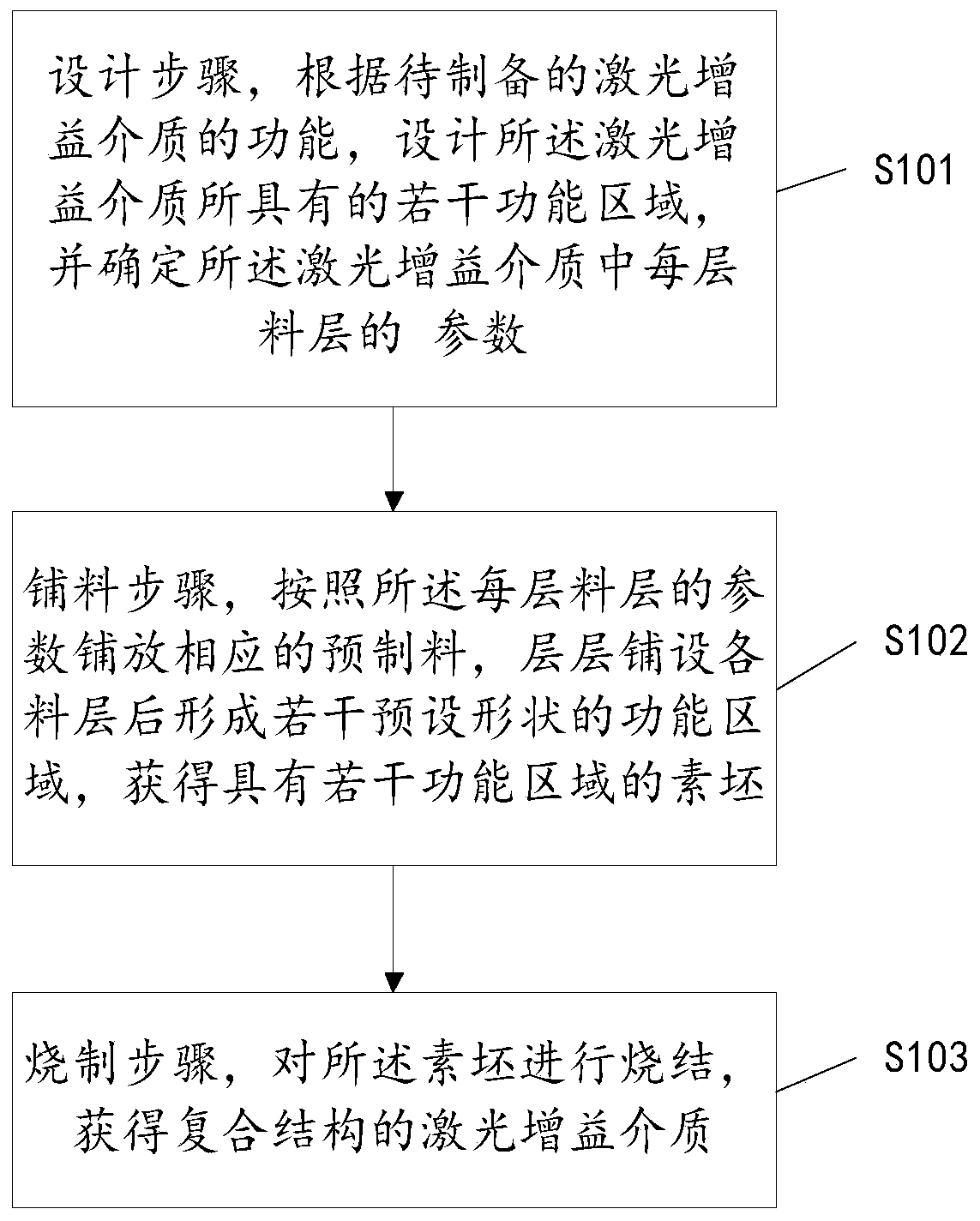

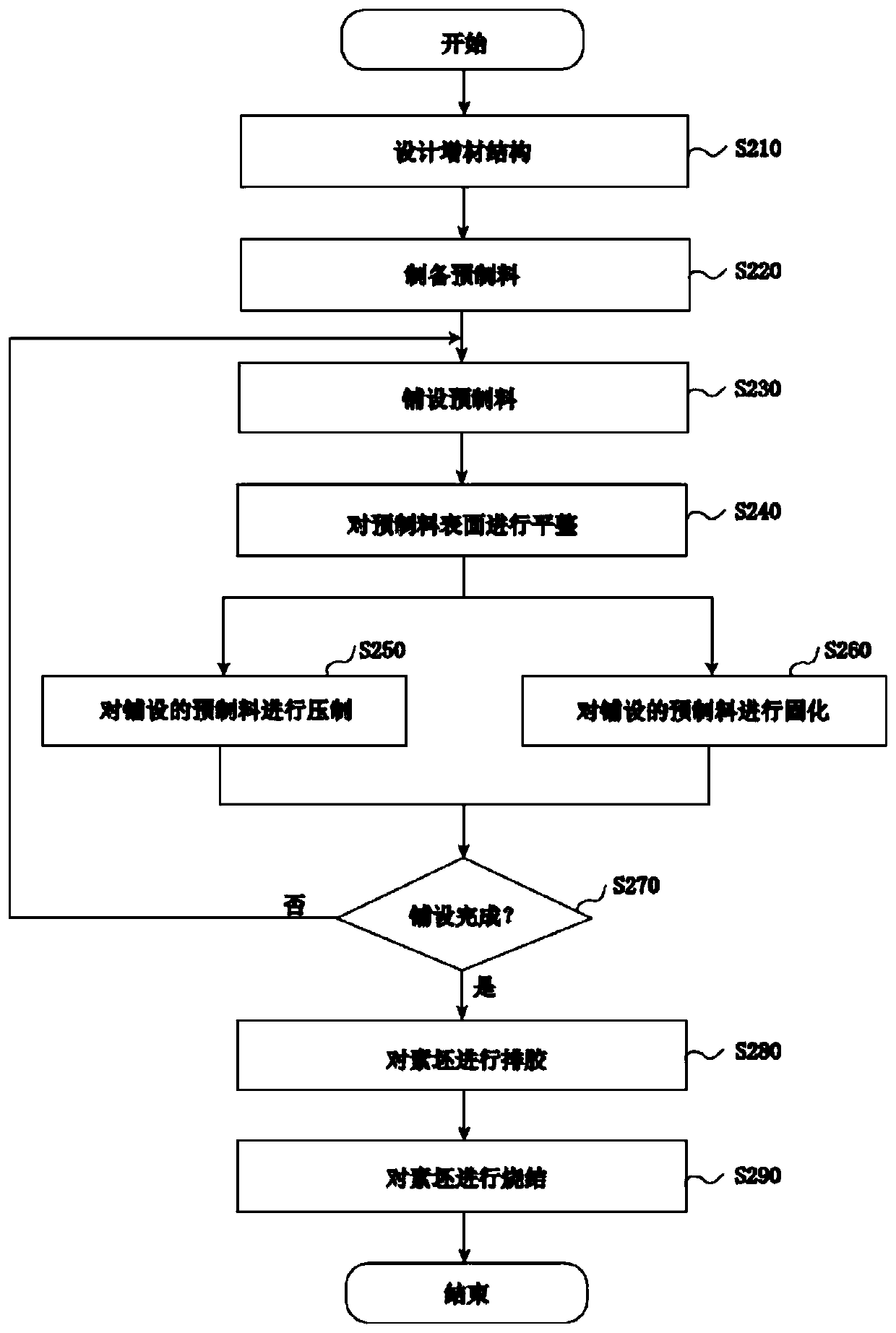

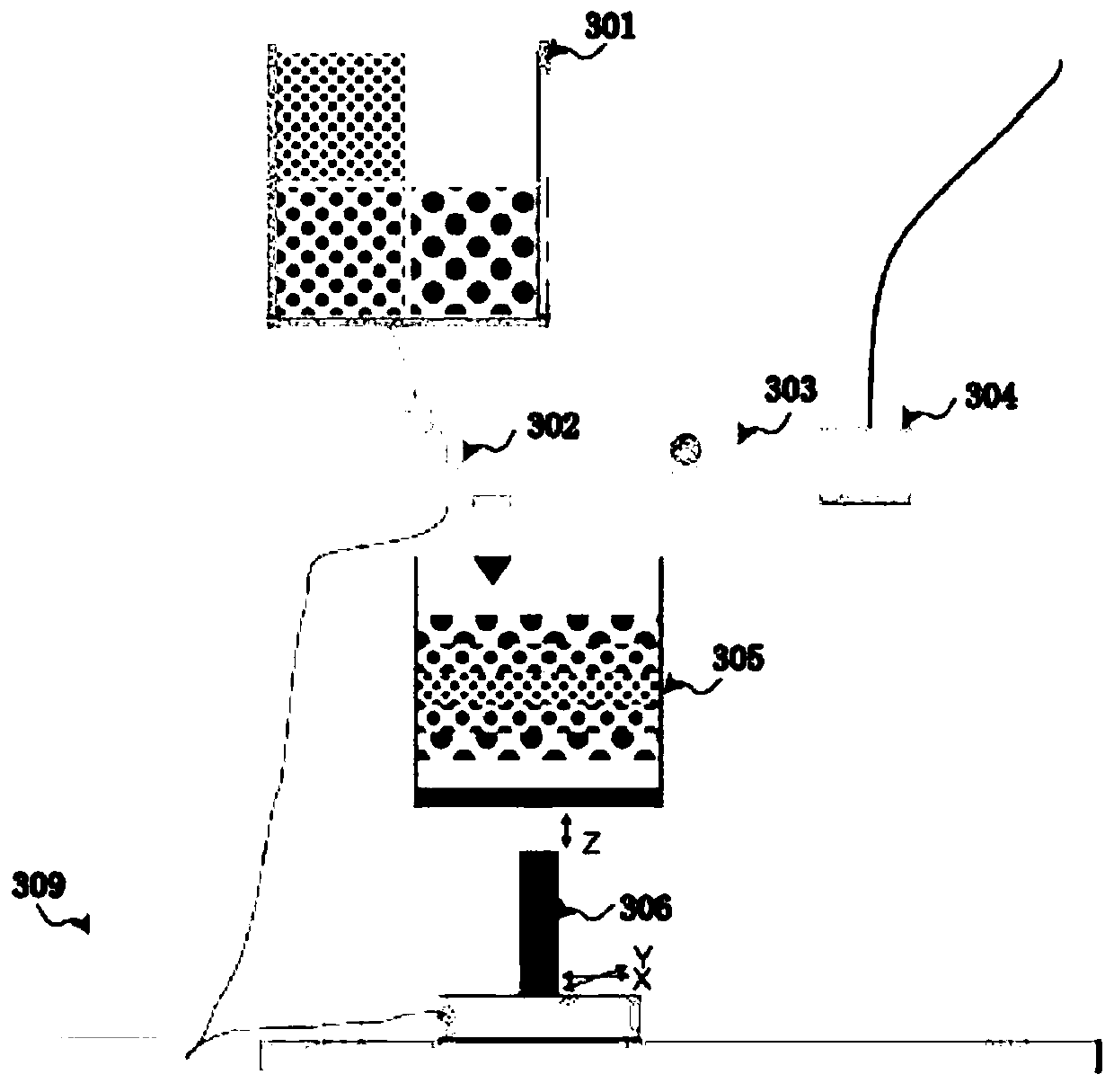

[0041] The first embodiment of the present invention provides a method for preparing a composite structure laser gain medium, such as figure 1 shown, including the following specific steps:

[0042] Step S101, according to the function of the laser gain medium to be prepared, design several functional areas of the laser gain medium, and determine the parameters of each material layer in the laser gain medium;

[0043] Step S102, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com