Thermoelectric insulating medium fault simulation device

A technology of fault simulation device and insulating medium, which is applied in the direction of testing dielectric strength and test ship construction, and can solve problems such as high overheating temperature, limited temperature resistance of insulating materials, and inability to simulate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

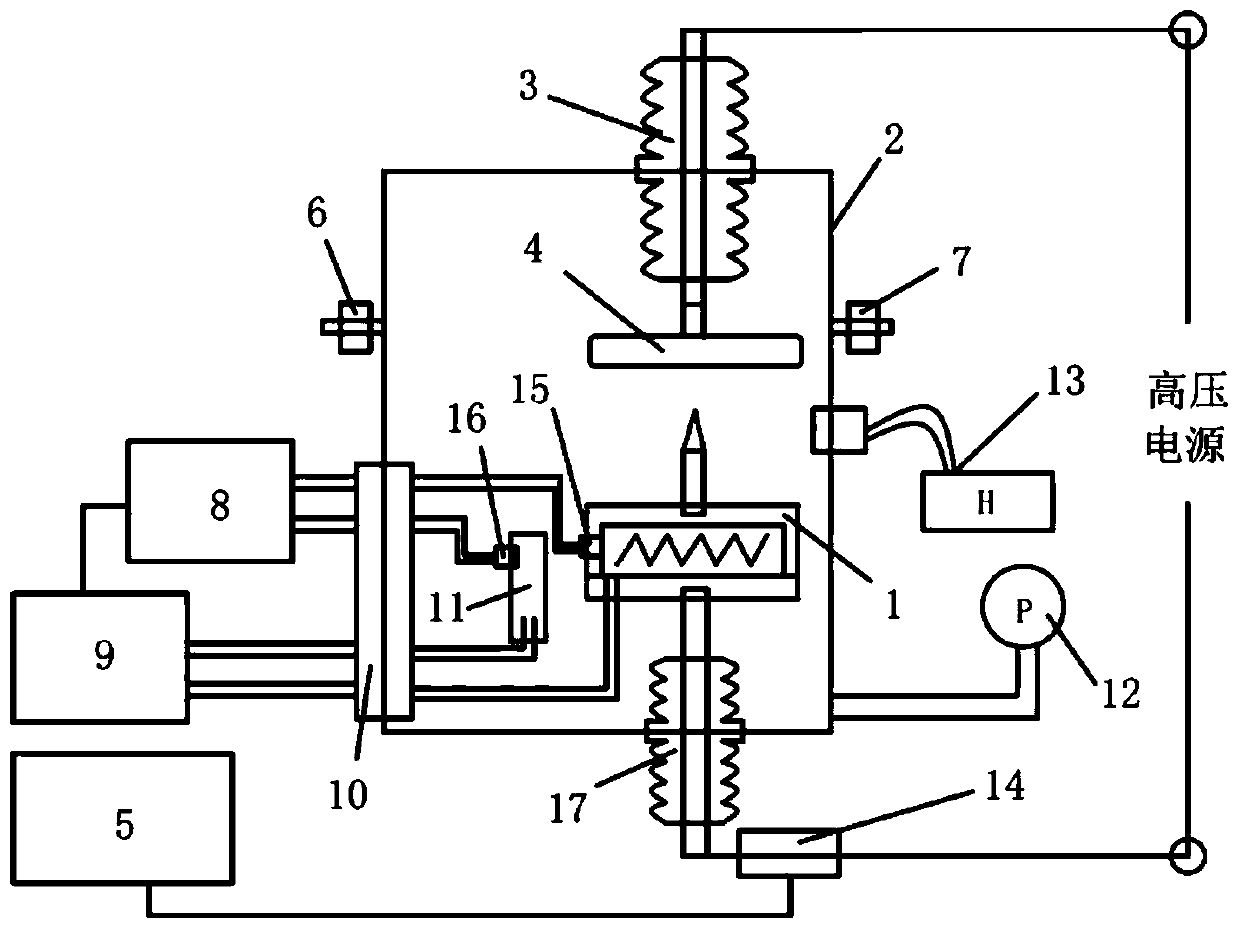

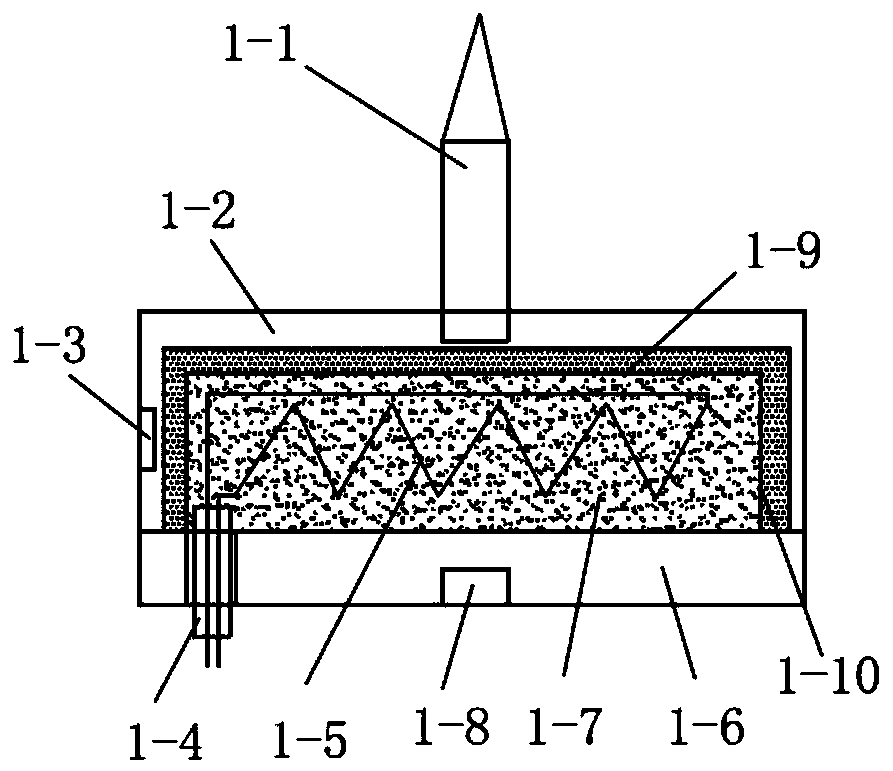

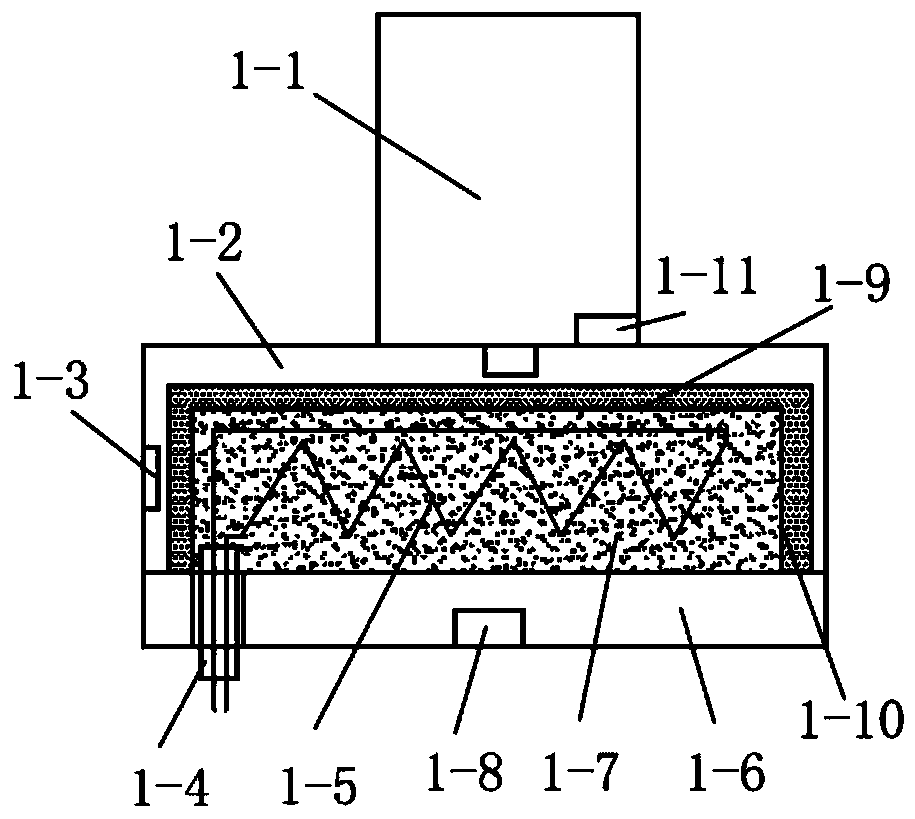

[0027] figure 1 It is a schematic diagram of an embodiment of the insulation medium failure simulation device with thermal-electric composite action of the present invention. Such as figure 1 As shown, the insulation medium failure simulation device of the present invention includes a sealed container 2, a self-heating electrode module 1, a high-voltage electrode 4, a high-voltage wall-through bushing 3, a low-voltage wall-through bushing 17, a sample inlet 6, a sampling port 7, and a discharge detection Device 5, temperature controller 8, heating power supply 9, plate-through flange 10, electric heating rod 11, pressure detector 12, micro-water detector 13, discharge signal sensor 14, first temperature sensor 15, and second temperature sensor 16.

[0028]The sealed container 2 is filled with an insulating medium through the injection port 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com