A processing technology and processing system for longitudinal wrapping of flame-retardant cables

A processing system and vertical wrapping technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problem that the finished cable flame retardant mud is easily powdered, the thickness of the fire retardant mud layer is uneven, and the fire retardant of the cable is affected. effect and other issues, to achieve the effect of reducing labor and equipment costs, reducing transportation costs and transportation difficulties, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

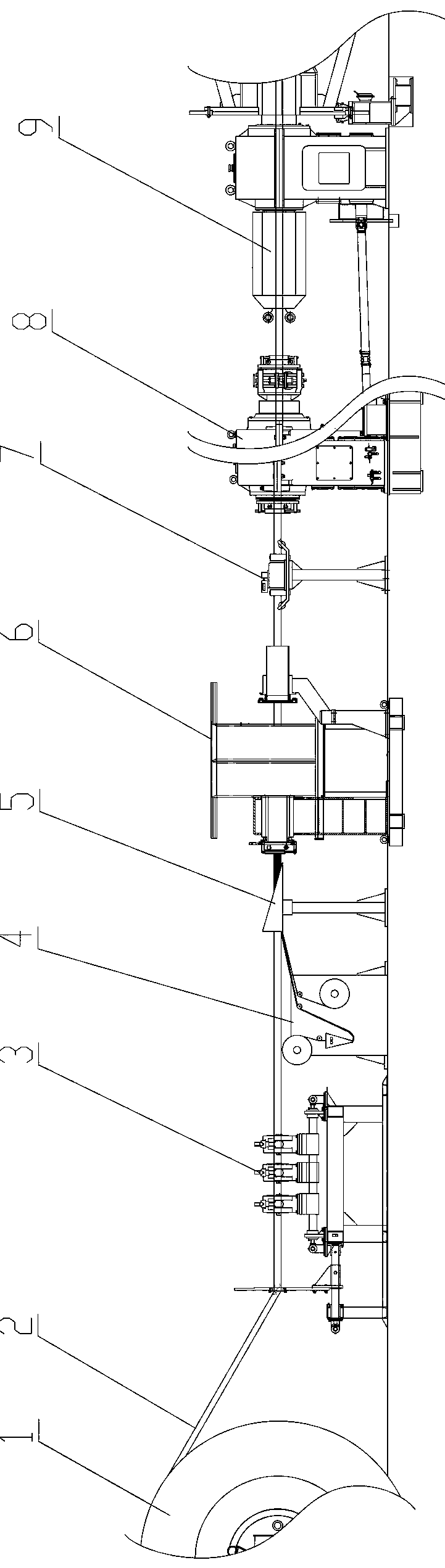

[0040] The invention includes a flame-retardant cable longitudinal wrapping process and a processing system.

[0041] The processing technology includes the following steps:

[0042] A. Select cable core 2;

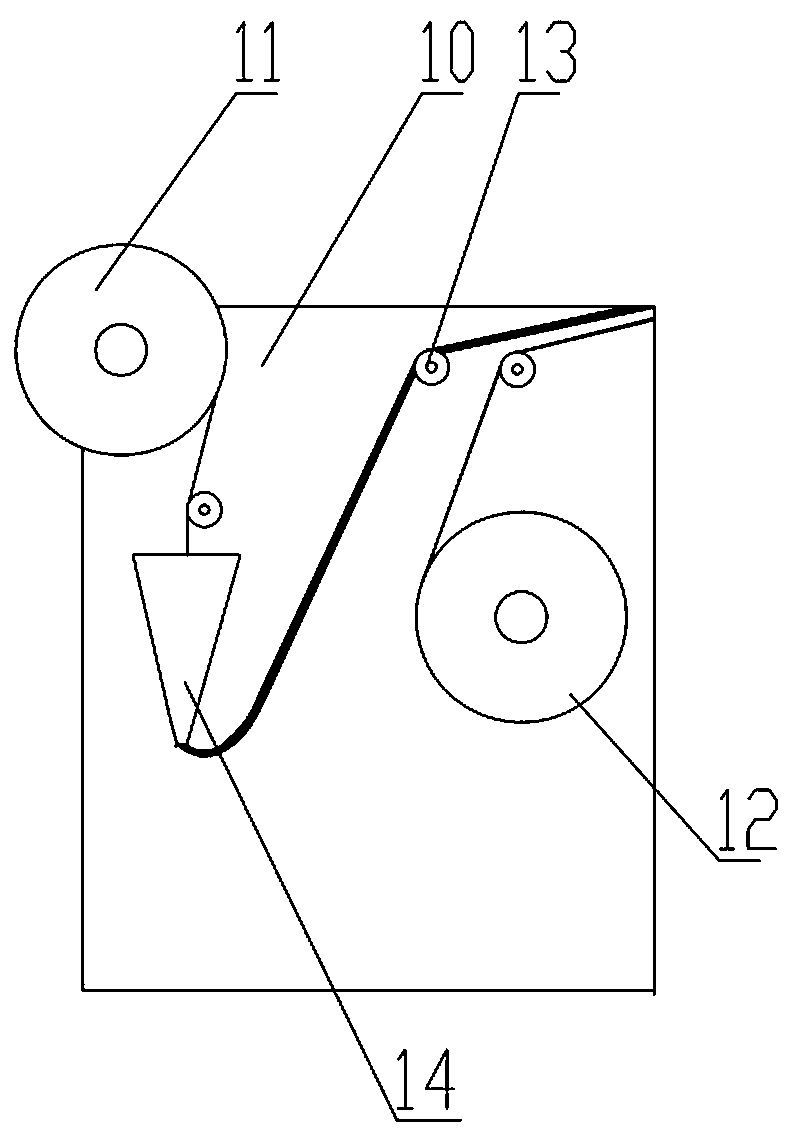

[0043] B. Coat the flame-retardant mud on the mesh tape and make it into a flame-retardant mesh tape; the specific process is as follows:

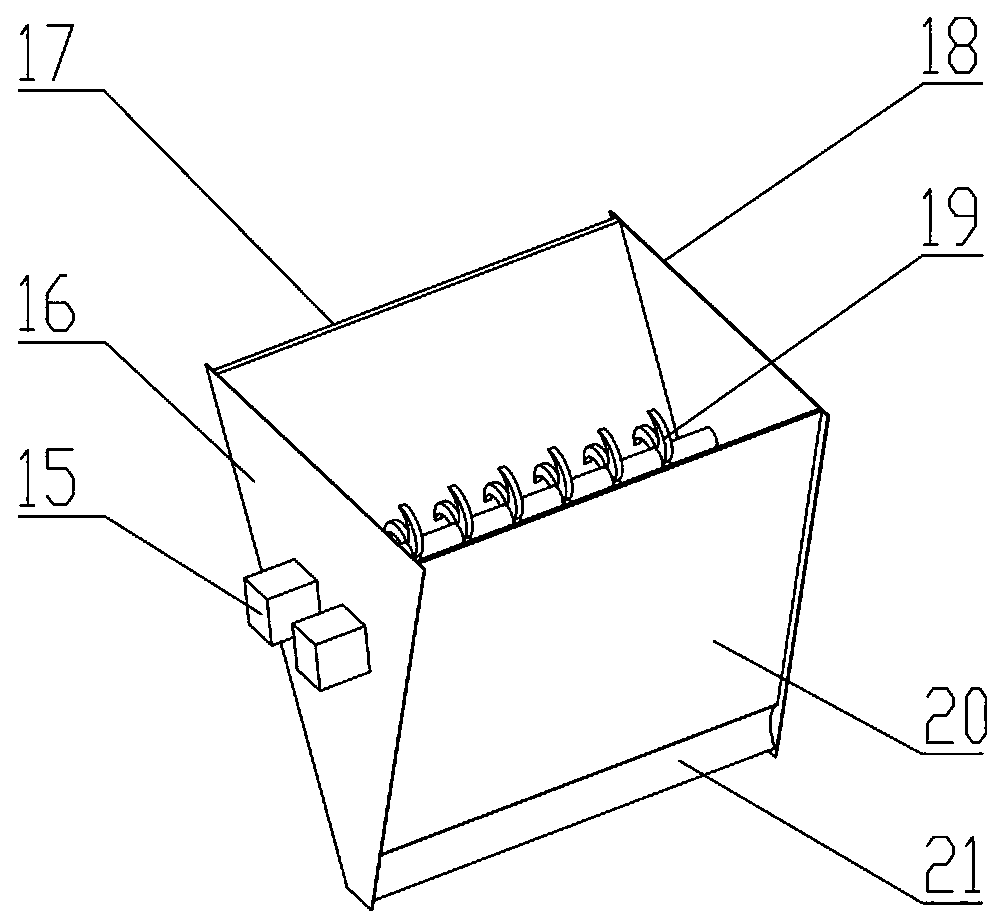

[0044]b1: Select the mesh tape and pass the head end of the mesh tape from top to bottom through the flame-retardant mud holding mold; the flame-retardant mud holding mold is provided with a strip-shaped outlet for the mesh tape to protrude; the mesh bag The belt width is 15mm~100mm, and the mesh tape density is 2 mesh~35 mesh;

[0045] b2: Load the fire-resistant and flame-retardant mud into the mold containing the fire-resistant mud;

[0046] b3: The grid tape is stretched downward, and the mesh tape pulled out from the fire-retardant mud holding mold is evenly coated with fire-resistant and flame-retardant mud to form a flame-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com