Environment-friendly fluff recovering machine

A technology for recycling machines and fluff, which is applied in the installation of suction filters, motor fan components, and cleaning equipment, etc. It can solve problems such as inability to meet large-scale production requirements, affect breeding effects, and incomplete recycling, so as to save manpower and eliminate The effect of random flying and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

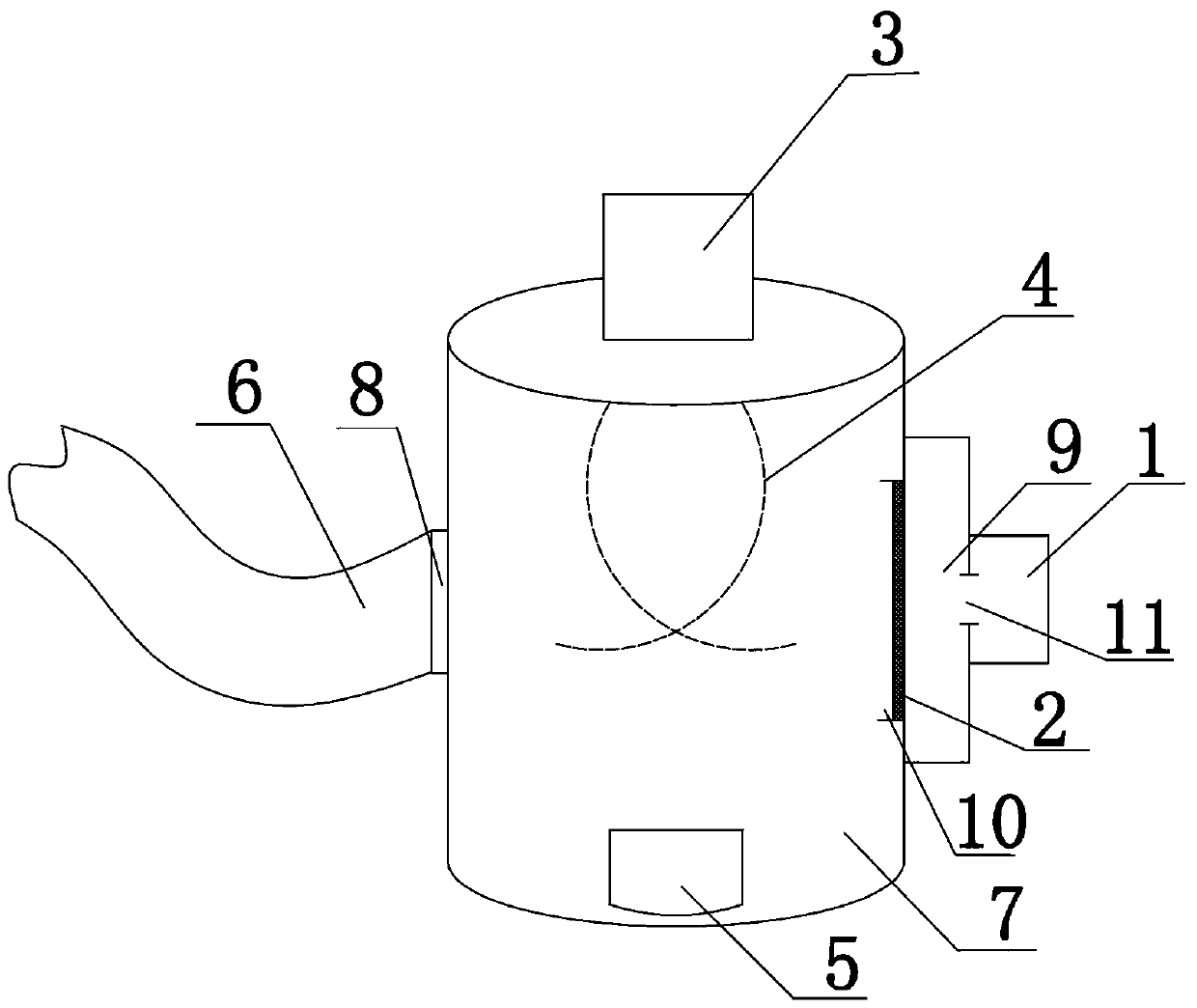

[0020] Such as figure 1 As shown, the environment-friendly fluff recovery machine of the present invention is characterized in that it comprises a fluff recovery bucket 7, and the geared motor 3 arranged at the top of the fluff recovery bucket 7 is connected with the output end of the geared motor 3 and extends into the The screw presser 4 inside the fluff recycling bucket 7 is arranged on the suction port 8 on one side of the barrel wall of the fluff recycling bucket 7, and the suction duct 6 connected with this suction port 8 is arranged on the fluff recycling bucket 7 The fan cover 9 on the other side of the barrel wall, the centrifugal fan 1 connected with this fan cover 9, is arranged on the barrel wall of the fluff recovery barrel 7 and is positioned at the hair outlet 5 at the bottom,

[0021] An air suction port II10 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com