Microwave method for large-scale and rapid improvement of hydrophilicity of carbon base and application thereof

A carbon-based, hydrophilic technology, applied in the field of improvement of functional materials, can solve the problems of high cost, complex production process, high energy consumption, etc., and achieve the effect of low equipment, simple experimental steps, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

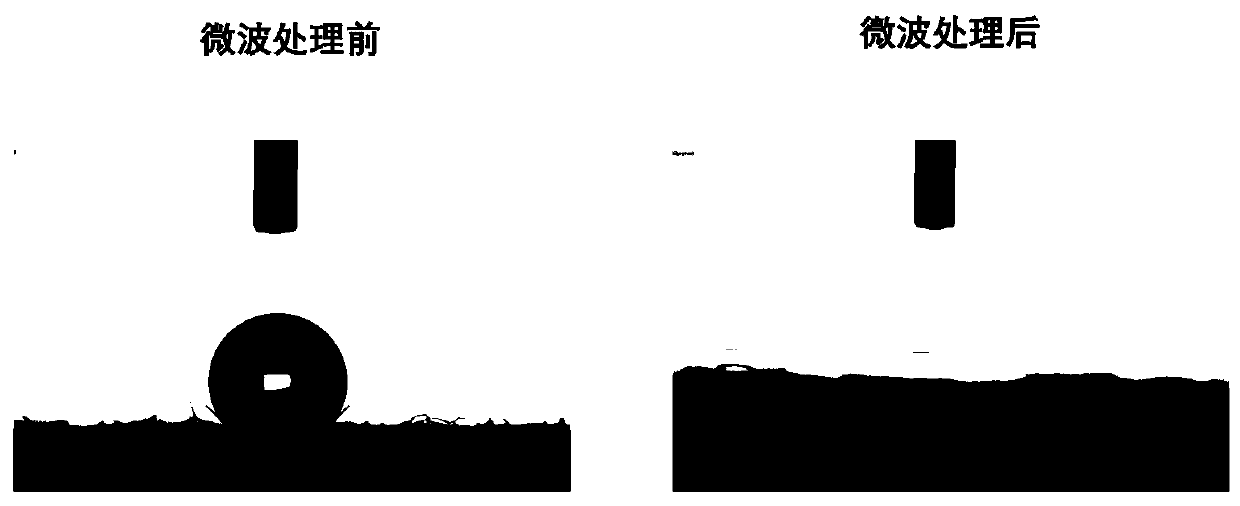

[0035] Take two pieces of 10*10cm carbon cloth, one of them is placed in a microwave reactor for microwave reaction for 120s, and the other piece is not treated at all. Drop 1 to 20 drops of water on it with a dropper, and you can observe the microwave reaction. The phenomenon of arc discharge ignition is eliminated, and the hydrophilicity of the carbon cloth after microwave treatment is much greater than that of carbon cloth without any treatment (such as figure 1 )

Embodiment 2

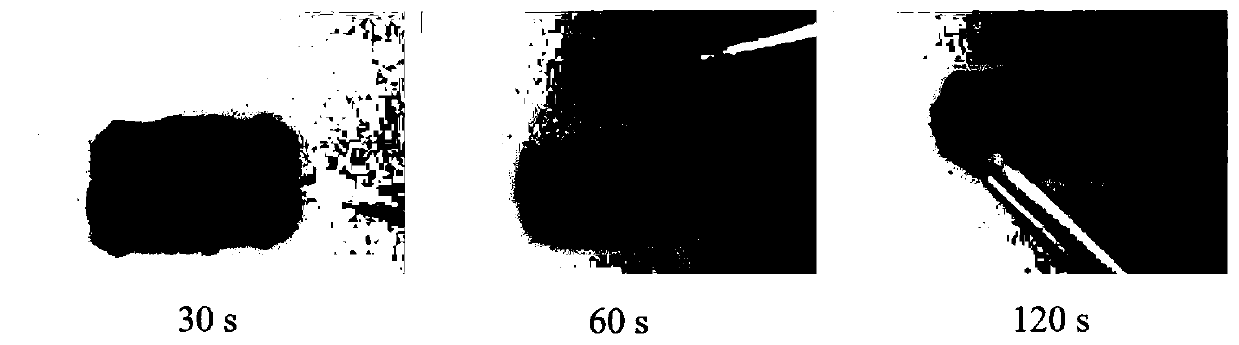

[0037] Put 3 small pieces of carbon cloth with a size of 3*4cm directly into a microwave reactor filled with air, and carry out microwave reactions for 30s, 60s (2 times of 30s), 120s (4 times of 30s), and then spray the surface with drops Pipe drops 1 to 20 drops of water, and it can be observed that arc discharge and ignition have occurred in the microwave reaction, and the hydrophilic properties of the products have been improved, and the carbon cloth has the best hydrophilic properties after microwave treatment for 120s (such as image 3 )

Embodiment 3

[0039] Put 3 small pieces of carbon cloth with a size of 3*4cm directly into the N 2 In the microwave reactor, the microwave reaction was carried out for 30s, 60s, and 120s respectively, and then 1 to 20 drops of water were dropped on the surface with a dropper respectively. It can be observed that arc discharge phenomenon occurred in the microwave reaction, and the hydrophilic properties of the products were obtained. Greatly improved, and the carbon cloth has the best hydrophilic performance after microwave treatment for 120s (such as Figure 4 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com