Active deformation compensation clamping device for ultra-precision cutting of soft and brittle ultra-thin crystals

A clamping device and active deformation technology, which is applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of inconsistent thickness and deformation of various points of the product, and achieve the improvement of ultra-precision cutting processing accuracy and high reliability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Active deformation compensation clamping device for ultra-precision cutting of soft and brittle ultra-thin crystals, which is fixedly installed above the vacuum suction cup in the single-point diamond ultra-precision lathe;

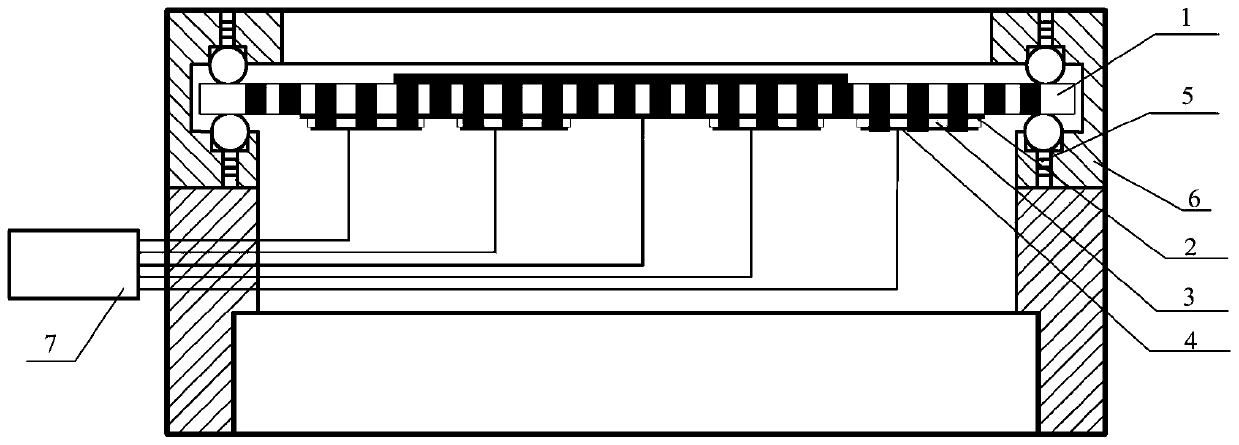

[0026] The clamping device includes a thin glass plate 1, a built-in electrode 2, a piezoelectric ceramic 3, a back electrode 4, a flexible support column 5, a deformation unit installation frame 6 and a voltage regulating circuit 7;

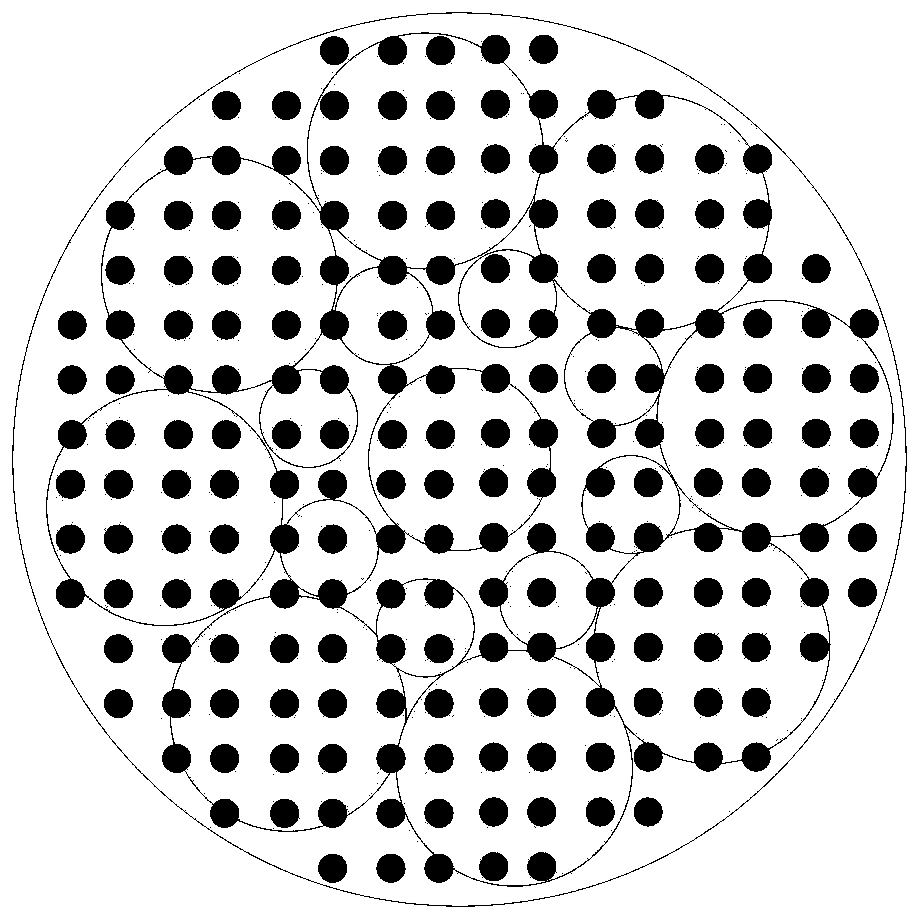

[0027] The installation frame 6 of the deformation unit is a two-body structure, and the two-body structure is assembled to form a concave-shaped structure, that is, there is a groove in the middle; the two-body structure is respectively equipped with a flexible support column 5; the built-in electrode 2 and the back electrode 4 respectively located on both sides of the piezoelectric ceramic 3, and then jointly fixed on the bottom surface of the glass sheet 1 to form a clamped part; the clamped part is fixed in the de...

Embodiment 2

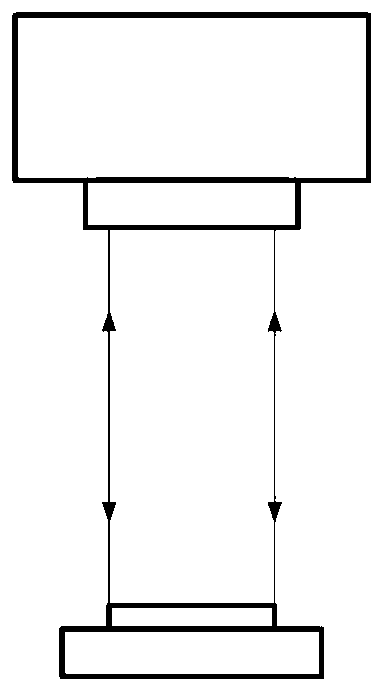

[0035] combine Figure 5 To illustrate this embodiment, the cesium iodide crystal size is φ25.4mm×100μm, and the active deformation compensation clamping device includes a glass thin plate with a diameter of 50mm, a built-in electrode chemical deposition of 200μm, a piezoelectric ceramic PZT-5A, a back electrode, a flexible support column, Deformation unit mounting frame, vacuum suction cup, vacuum generator.

[0036] like Figure 5 a, Vacuum adsorption deformation is PV 3.711 wavelength without active compensation, such as Figure 5 b, The vacuum adsorption deformation after active compensation is PV 0.931 wavelength, which meets the needs of ultra-precision cutting.

[0037] The active deformation compensation clamping device for ultra-precision cutting of soft and brittle ultra-thin crystals of the present invention can be widely used in ultra-precision cutting of scintillation crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com