Green energy-saving interior wall paint

A kind of interior wall paint, green technology, applied in the direction of fireproof paint, antifouling/underwater paint, coating, etc., can solve the problem of irritating odor easily emitted from interior wall, irritating odor of formaldehyde, human health impact, etc. , to achieve the effect of improving green environmental protection performance, not easy to be corroded by water, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

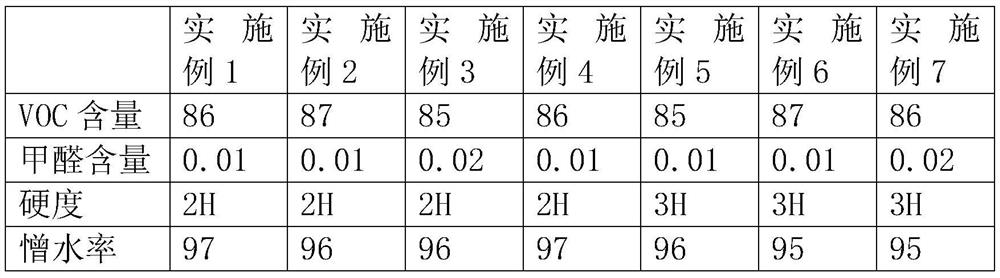

Examples

Embodiment 1

[0054] A green energy-saving interior wall paint, comprising the following components in parts by mass:

[0055] 50kg of water; 80kg of silicon-acrylic emulsion; 8kg of colored ceramic hollow microspheres; 5kg of nanoporous active silicon; 5kg of melamine; 10kg of octadecanoyl chloride.

[0056] The preparation method of the green energy-saving interior wall paint is as follows:

[0057] (1) In a 200L stirred tank, under normal temperature, add 80kg of silicon-acrylic emulsion, 8kg of colored ceramic hollow microspheres, 5kg of nanoporous active silicon, 5kg of melamine, and 10kg of octadecanoyl chloride, at a speed of 50r / min. stir;

[0058] (2) add water 50kg while stirring;

[0059] (3) After stirring and mixing evenly, the green and energy-saving interior wall paint is obtained.

Embodiment 2

[0061] A green energy-saving interior wall paint, comprising the following components in parts by mass:

[0062] 55kg of water; 90kg of silicon-acrylic emulsion; 9kg of colored ceramic hollow microspheres; 5.5kg of nanoporous active silicon; 7.5kg of melamine; 12.5kg of octadecanoyl chloride.

[0063] The preparation method of the green energy-saving interior wall paint is as follows:

[0064] (1) In a 200L stirred tank, under normal temperature conditions, add 90kg of silicon acrylic emulsion, 9kg of colored ceramic hollow microspheres, 5.5kg of nanoporous active silicon, 7.5kg of melamine, and 12.5kg of octadecanoyl chloride, at 50r / min Stir at a rotating speed;

[0065] (2) add water 55kg while stirring;

[0066] (3) After stirring and mixing evenly, the green and energy-saving interior wall paint is obtained.

Embodiment 3

[0068] A green energy-saving interior wall paint, comprising the following components in parts by mass:

[0069] 60kg of water; 100kg of silicon-acrylic emulsion; 10kg of colored ceramic hollow microspheres; 6kg of nano-microporous active silicon; 10kg of melamine; 15kg of octadecanoyl chloride.

[0070] The preparation method of the green energy-saving interior wall paint is as follows:

[0071] (1) In a 200L stirred tank, at room temperature, add 100kg of silicon-acrylic emulsion, 10kg of colored ceramic hollow microspheres, 6kg of nanoporous active silicon, 10kg of melamine, and 15kg of octadecanoyl chloride, at a speed of 50r / min. stir;

[0072] (2) add water 60kg while stirring;

[0073] (3) After stirring and mixing evenly, the green and energy-saving interior wall paint is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com