No-ferromagnetism, high-strength and high-cubic-texture nickel tungsten composite base belt and preparation method

A strong cubic texture and composite baseband technology, which is applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of obtaining strong cubic texture, the inability to effectively improve the strength, and the limited strength improvement. Achieving a strong cubic texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The steps of the preparation method of the inventive method embodiment 1 are as follows:

[0022] (1) Hot rolling of alloy ingots

[0023] The Ni-12at.% W nickel-tungsten alloy ingot obtained by smelting is hot-rolled. The hot-rolling process is as follows: the starting rolling temperature is 1300°C, the finishing rolling temperature is 1000°C, and the hot-rolling deformation is 90%;

[0024] (2) Cold rolling and recrystallization heat treatment of hot rolled sheet

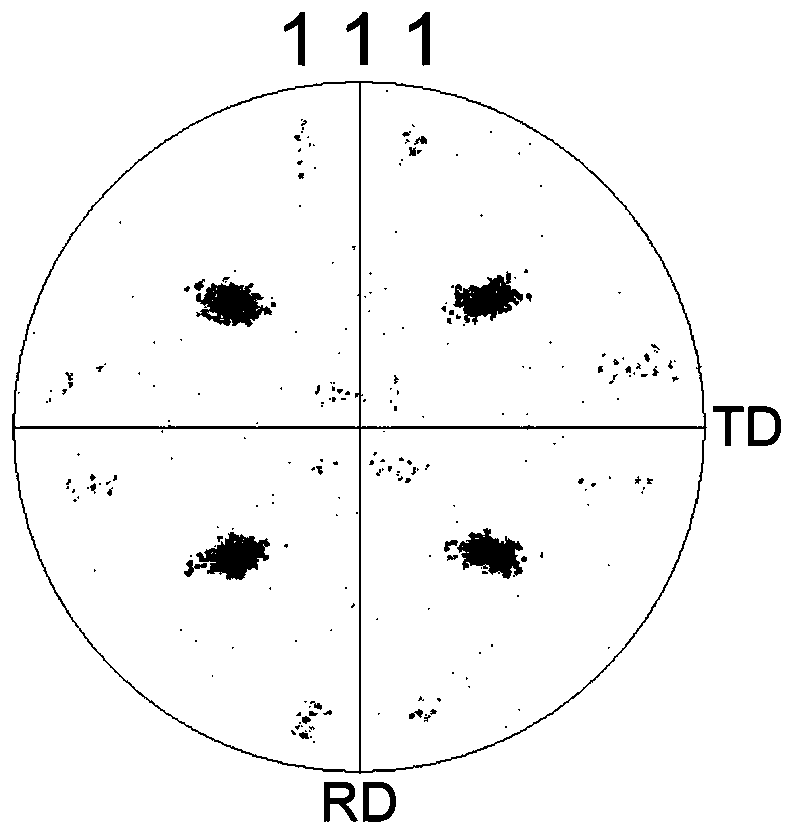

[0025] The obtained hot-rolled sheet is cold-rolled to a thickness of 50 μm, and then the cold-rolled strip is subjected to recrystallization heat treatment in pure hydrogen. The recrystallization heat treatment process is: 1280 ° C for 5 minutes;

[0026] (3) sputtering film

[0027] On the surface of Ni-12at.% W recrystallized strip obtained above, a layer of Ni-9at.% W alloy film is deposited by magnetron sputtering. The deposition process is: Ni-9at.% W prepared by vacuum induction melting The alloy ...

Embodiment 2

[0030] The steps of the preparation method of the embodiment of the present invention 2 are as follows:

[0031] (1) Hot rolling of alloy ingots

[0032] The Ni-12at.%W nickel-tungsten alloy ingot obtained by smelting is hot-rolled. The hot-rolling process is as follows: the starting rolling temperature is 1300°C, the finishing rolling temperature is 1030°C, and the hot-rolling deformation is 90%;

[0033] (2) Cold rolling and recrystallization heat treatment of hot rolled sheet

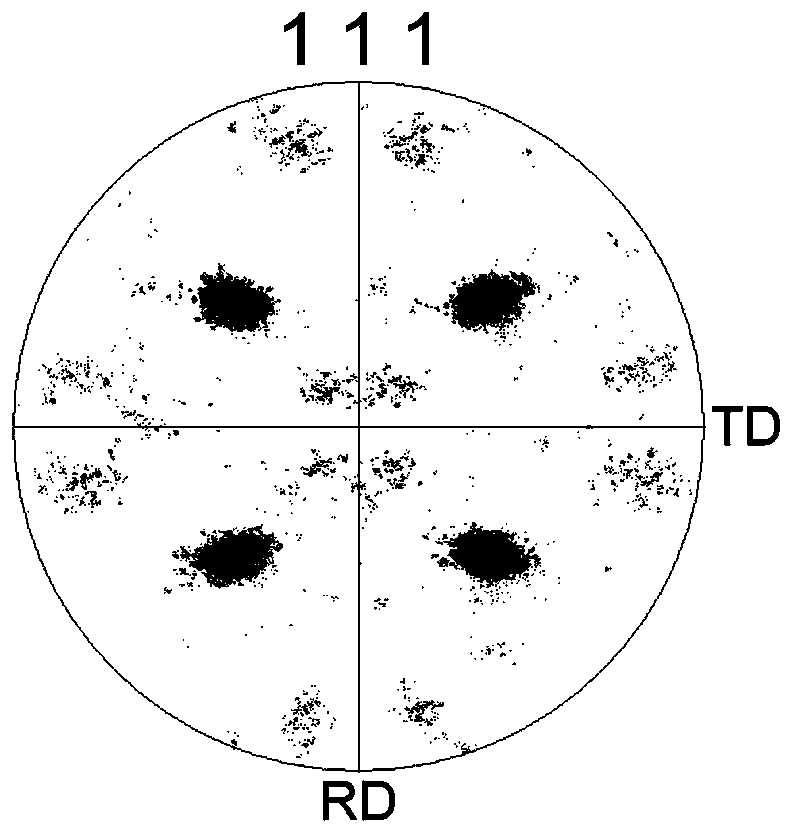

[0034] The obtained hot-rolled sheet is cold-rolled to a thickness of 50 μm, and then the cold-rolled strip is subjected to recrystallization heat treatment in pure hydrogen. The recrystallization heat treatment process is: 1300 ° C for 5 minutes;

[0035] (3) sputtering film

[0036] On the surface of Ni-12at.% W recrystallized strip obtained above, a layer of Ni-9at.% W alloy film is deposited by magnetron sputtering. The deposition process is: Ni-9at.% W prepared by vacuum induction melting The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com