Non-ferromagnetic Ni-based alloy base strip with cubic texture, and preparation method thereof

A technology of cubic texture and base alloy, applied in the field of iron-free magnetic cubic texture Ni-based alloy base belt and its preparation, can solve the problems of low yield strength, limited application range, hysteresis loss, etc., and achieve the effect of high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The steps of the preparation method of the inventive method embodiment 1 are as follows:

[0024] (1) Preparation of initial alloy billet

[0025] Firstly, a nickel-tungsten-carbon alloy ingot with carbon and tungsten atomic percentages of 0.005% and 9.5% is obtained by vacuum induction melting, and an initial alloy ingot is obtained by forging and hot rolling.

[0026] (2) Cold rolling of alloy billets

[0027] The initial alloy ingot obtained above is removed from scale and then subjected to large deformation cold rolling, with a total deformation of 99.6%, to obtain a nickel-tungsten-carbon alloy cold-rolled base strip.

[0028] (3) Recrystallization heat treatment of cold-rolled alloy base strip

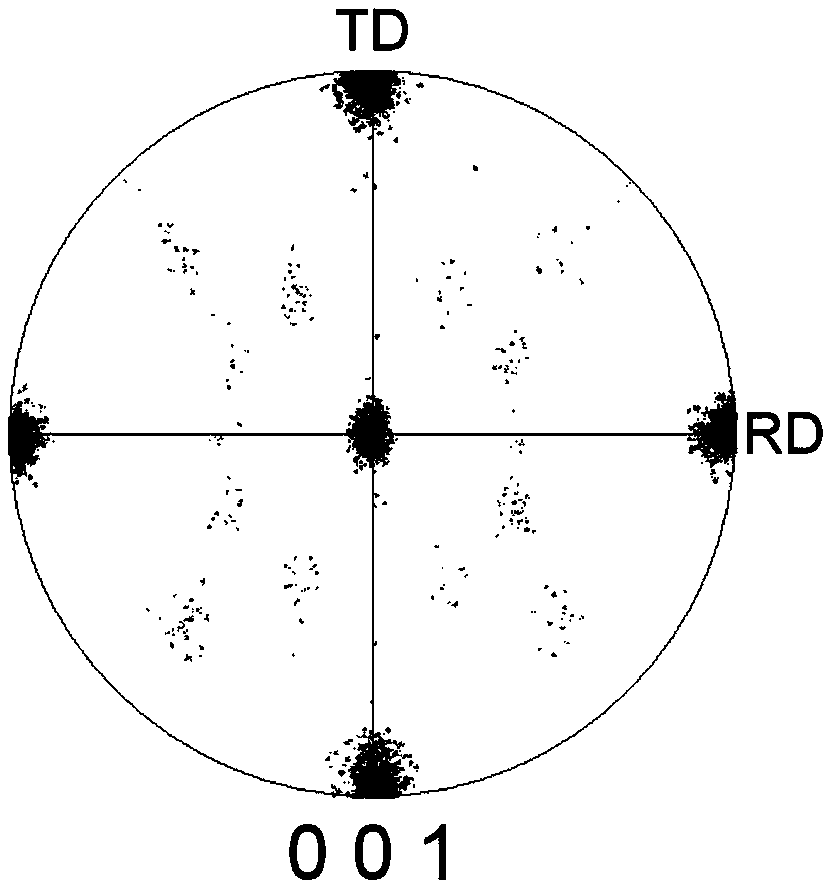

[0029] The cold-rolled alloy base strip obtained above is subjected to recrystallization heat treatment to obtain a nickel-tungsten carbon alloy base strip with strong cubic texture. The recrystallization heat treatment process is: 1230°C for 2 hours, the heating rate is...

Embodiment 2

[0032] The steps of the preparation method of the method embodiment 2 of the present invention are as follows:

[0033] (1) Preparation of initial alloy billet

[0034] First, vacuum induction melting is used to obtain nickel-tungsten-carbon alloy ingots with carbon and tungsten atomic percentages of 0.01% and 9.5%, respectively, and initial alloy ingots are obtained by forging and hot rolling.

[0035] (2) Cold rolling of alloy billets

[0036] The initial alloy ingot obtained above is removed from scale and then subjected to large deformation cold rolling, with a total deformation of 99.6%, to obtain a nickel-tungsten-carbon alloy cold-rolled base strip.

[0037] (3) Recrystallization heat treatment of cold-rolled alloy base strip

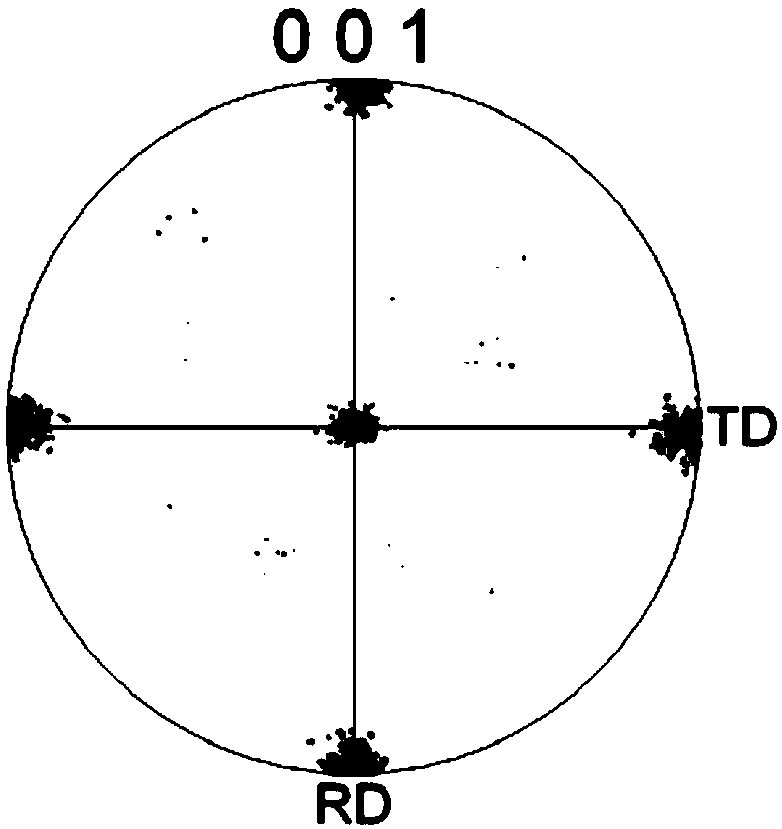

[0038] The cold-rolled alloy base strip obtained above is subjected to recrystallization heat treatment to obtain a nickel-tungsten carbon alloy base strip with strong cubic texture. The recrystallization heat treatment process is: 1280°C for 2...

Embodiment 3

[0041] The steps of the preparation method of the inventive method embodiment 3 are as follows:

[0042] (1) Preparation of initial alloy billet

[0043] Firstly, nickel-tungsten-carbon alloy ingots with carbon and tungsten atomic percentages of 0.007% and 9.5% were obtained by vacuum induction melting, and initial alloy ingots were obtained by forging and hot rolling.

[0044] (2) Cold rolling of alloy billets

[0045] The initial alloy ingot obtained above is removed from scale and then subjected to large deformation cold rolling, with a total deformation of 99.6%, to obtain a nickel-tungsten-carbon alloy cold-rolled base strip.

[0046] (3) Recrystallization heat treatment of cold-rolled alloy base strip

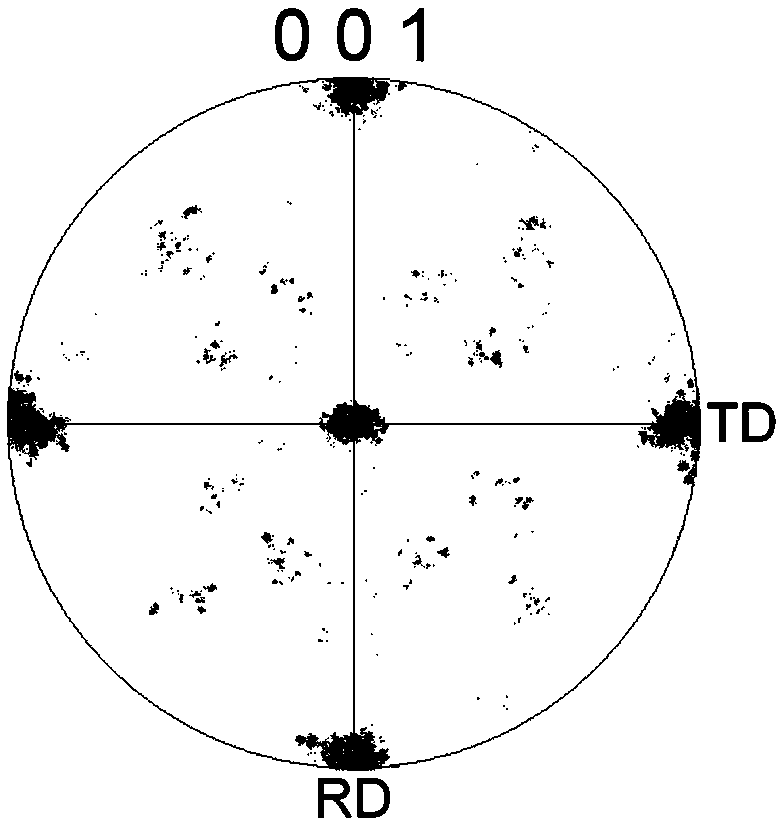

[0047] The cold-rolled alloy base strip obtained above was subjected to recrystallization heat treatment to obtain a nickel-tungsten carbon alloy base strip with strong cubic texture. The recrystallization heat treatment process was: 1250°C for 2 hours, the heating rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com